Error

Maximum number of iterations exceeded when calculating temperature from a thermodynamic potential. This may be caused by low-quality mesh producing unrealistic pressure in a few cells. Inspect fields for large values in the last time step.

What Happened?

The simulation stopped because the solver exceeded the maximum number of iterations, without being able to reach the specified tolerances in a given time step.

What Could Be the Possible Reason?

This error may occur due to several problems. Find below the most common ones:

- Low mesh quality

- Poor definition of boundary conditions, which cause flow variables to reach extremely large or non-physical values

- Severe inflow/outflow conditions

- Poor definition of fluid materials’ properties

- Inappropriate time step size, for transient simulations

What Can I Do Now?

- One of the most common causes of this error is a poor mesh quality. So, as a first step, please examine the mesh thoroughly. Inspect the surfaces, making sure there are no distorted cells. The meshing log and the mesh quality feature also provide valuable insight. Find in this article the step-by-step procedure for checking and improving the mesh quality.

- If a data set was saved for the simulation run, use the isovolumes filter to spot cells with unrealistic levels for the parameters (e.g., pressure or temperature). This will give you additional information about the problematic regions.

- Ensure that the boundary conditions are correct and have appropriate values. Please see our boundary condition documentation for details of their implementation. Furthermore, our step-by-step tutorials can also be used as a reference.

- If the flow conditions are severe, for example, involving high velocity or pressure inlet boundary conditions, consider using a table input to ramp the values for the first few hundred iterations. This practice enhances the stability of the simulation. The steps to ramp an inlet boundary condition are explained in detail in this tutorial.

- If you’re running a conjugate heat transfer analysis, verify the CAD model, looking for gaps between parts that should be in contact. If there are gaps present, no heat will be exchanged between the two parts.

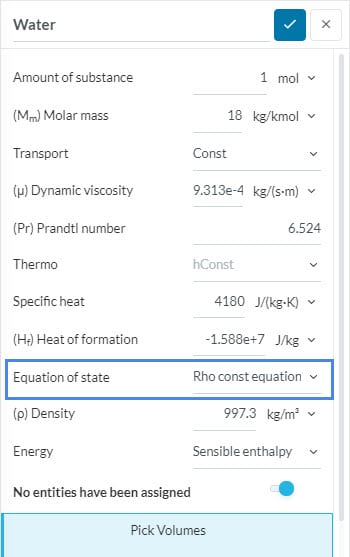

- Again, for the conjugate heat transfer analysis type, please check the Equation of state defined for the fluid materials, making sure it’s adequate (e.g., defining Perfect gas for water may result in iterations exceeded error). The formulation for the various equations of state is given in this documentation page.

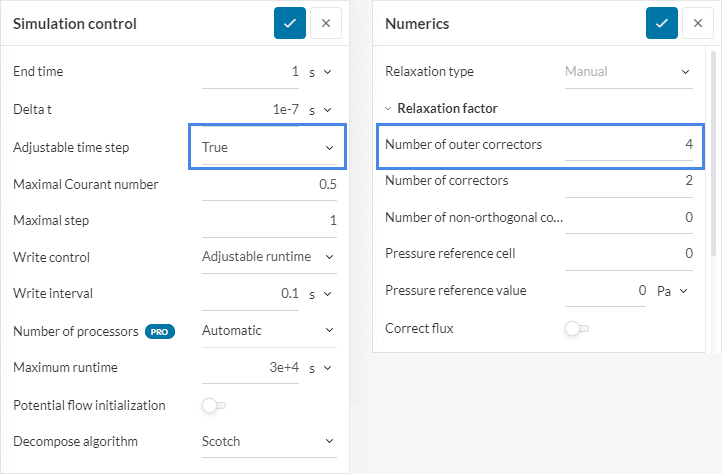

- In the case of transient analysis, navigate to the Simulation control tab and set Adjustable time step to ‘True’. Additionally, under Numerics, ensure that the Number of outer correctors is set to at least ‘4’.

- In the Numerics tab, use lower values for the Relaxation factors. Read more on it in this forum discussion.

Important Information

If none of the above suggestions solved your problem, then please post the issue on our forum or contact us.