Documentation

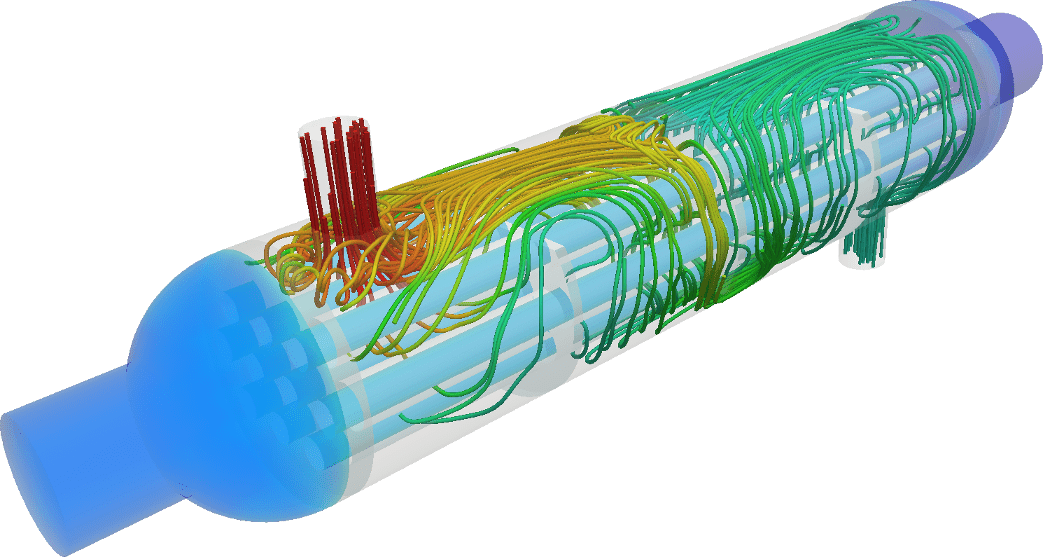

The Conjugate Heat Transfer v2.0 (CHT v2.0) analysis type allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them. Typical applications of this analysis type exist as, but are not limited to, the simulation of heat exchangers, cooling of electronic equipment, and general-purpose cooling and heating systems.

The following section will explain the step-by-step procedure to set up a conjugate heat transfer v2.0 simulation within the SimScale platform:

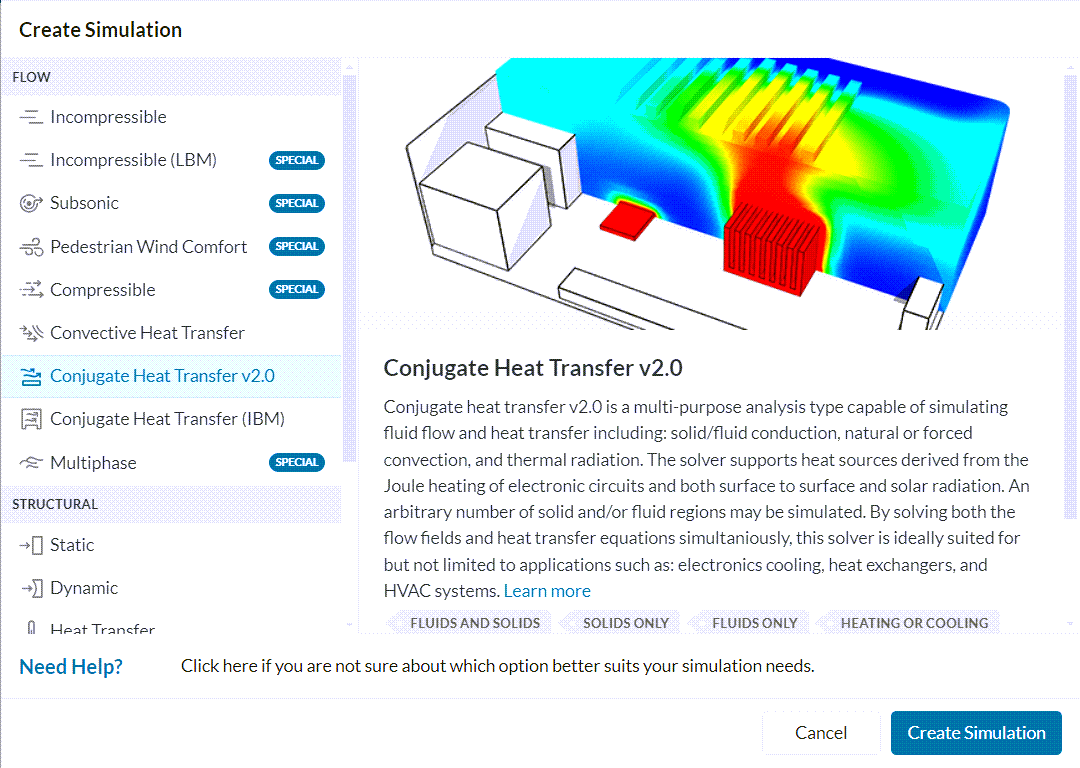

To create a CHT v2.0 analysis, first, select the desired geometry and click on ‘Create Simulation’:

Please note that .stl models are not supported for CHT v2.0 analyses. A list of alternative supported CAD formats can be found here.

Next, a window with a list of analysis types supported in SimScale will be displayed:

Choose Conjugate Heat Transfer v2.0 analysis type and click on ‘Create Simulation’. This will lead to the Workbench for the simulation with the following simulation tree and the respective settings:

To access the global settings, click on ‘Conjugate Heat Transfer v2.0’ in the simulation tree. It consists of certain parameters that can be selected to define the simulation. The parameters are listed below:

Find detailed information on each parameter here.

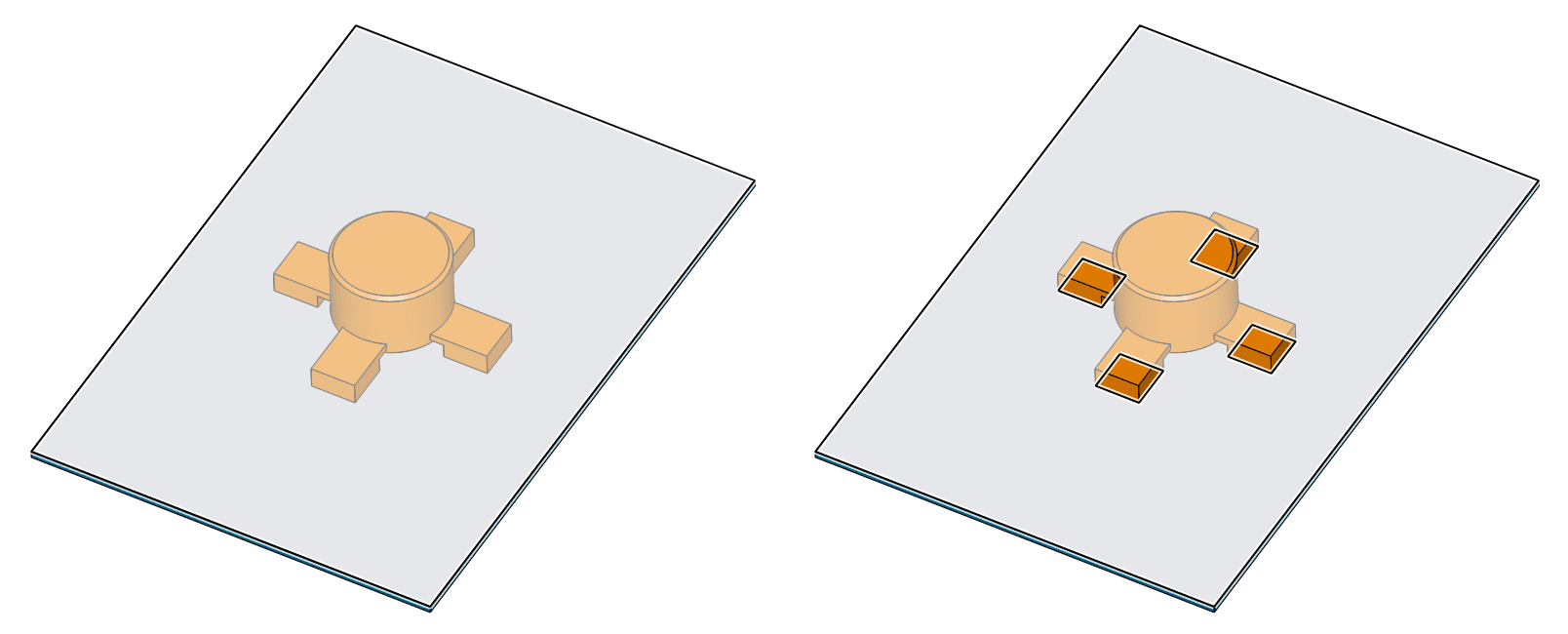

When performing a Conjugate Heat Transfer v2.0 analysis, additional CAD requirements have to be taken into account. These include:

Our knowledge base article offers a quick guide into satisfying these two major CAD requirements.

Under Contacts, one should see all the interfaces listed. Interfaces are required for simulating heat transfer between two regions. When creating a CHT v2.0 simulation or when assigning a new simulation domain to an existing simulation, all interfaces will automatically be detected by the platform. It is required that these interfaces are defined by two congruent faces on both contacting regions. In case this requirement is not met by the assigned CAD model, the platform will recommend an automatic Imprinting operation, which splits existing faces into multiple parts in order to guarantee perfect overlaps.

As mentioned, all possible interfaces will automatically be detected upon simulation creation and domain assignment.

Under Model, gravity can be defined. In case LES Smagorinsky has been set as a turbulence model, its cutoff length and other parameters related to the delta coefficient can be defined too. Find further information here.

The CHT v2.0 analysis type allows you flexibility with the materials being used in the simulation. That is, it can be used with only flow regions, only solids, or a combination of both.

Basically, users can now run conjugate, convective, and simple heat transfer simulations within CHT v2.0, with the intention of leveraging its better numerics and radiation model for other types of simulations. Read more in the dedicated document on materials in SimScale.

In a conjugate heat transfer simulation, the computational domain will be solved for three fields: pressure \((P)\) and velocity \((U)\), and temperature \((T)\). Here the pressure is referred to as Modified pressure and takes absolute values only. Additional turbulent transport quantities may be included based on the turbulence model selected. Under Initial conditions, these values can be initialized for the whole domain or a sub-domain for each region.

Important

For any simulation, initial and boundary conditions must be specified for all required variables on every boundary.

It is recommended to set the initial conditions close to the expected solution to avoid potential convergence problems. Learn more about initial conditions in this document.

Boundary conditions help to add a closure to the problem in hand by defining how a system interacts with the environment. This detailed list of available boundary conditions leads to dedicated pages each explaining their importance and how they can be applied to the domain boundaries.

Some boundary conditions available in conjugate heat transfer simulations are supported in parametric experiments. Find more details about parametric studies in this article.

Important

In case no boundary conditions are assigned to a face, by default it will receive a no-slip wall boundary condition with wall function for turbulence resolution.

Under Advanced concepts, you will find additional setup options, such as Rotating zones, Momentum sources, Power sources, and Thermal Resistance Networks. Visit this dedicated page for more information.

Furthermore, momentum sources, power sources, and rotating zones are supported in parametric experiments. This dedicated article contains more information on parametric studies.

Numerical settings play an important role in the simulation configuration. They define how to solve the equations by applying proper discretization schemes and solvers to the equations. They help enhance the stability and robustness of the simulation. Although all numerical settings are made available for users to have full control over, it is advised to keep them default unless necessary.

Note

SimScale uses its own version of OpenFOAM® solvers developed in-house.

Numerical settings are recommended for advanced users but interested readers are encouraged to learn more about them through this documentation.

The Simulation Control settings define the general controls over the simulation. In these settings the number of iterations, simulation interval, timestep size, and several other variables can be set. Find further information here.

The Result Control section allows users to define additional simulation result outputs. It controls how the results will be written meaning the write frequency, location, statistics of the output data, etc.

Find more details about result controls here.

Meshing is the process of discretization of the simulation domain. That means we split up a large domain into multiple smaller domains and solve equations for them.

A multi-region mesh is required for a conjugate heat transfer simulation to have a clear definition of the interfaces in the computational domain. With the interfaces properly defined, this is automatically taken care of in SimScale. To learn more about the mesh settings in SimScale and its upload, visit this page.

Take a look at the following tutorial to get started with conjugate heat transfer v2.0 analysis on SimScale:

Interested in more? Quickly check out our page for all the basic and advanced tutorials.

Last updated: April 26th, 2024

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now