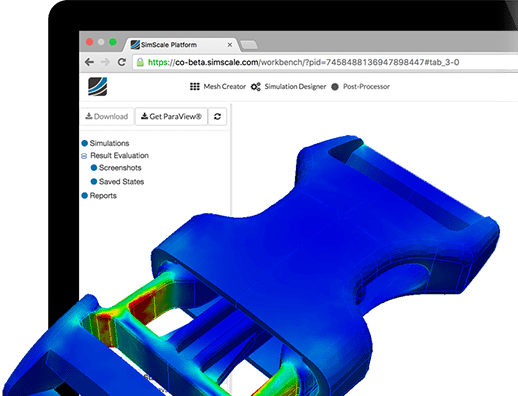

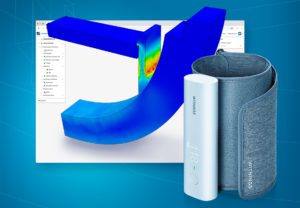

SimScale enables consumer product companies to simulate and optimize their designs to produce better products.

Reduced time-to-market and constant decreases in production costs are the drivers behind most consumer products. Products need to become cheaper and innovation cycles shorter. With simulation, companies have a reliable way to fulfill these needs.

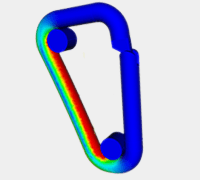

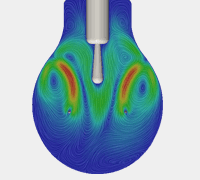

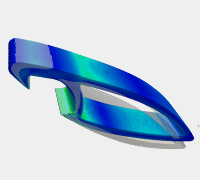

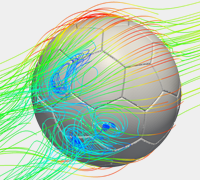

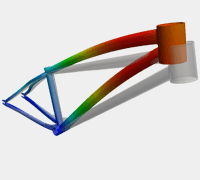

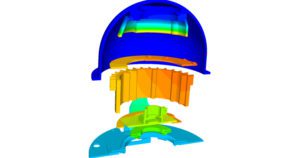

Cloud-based, robust, and easy to use, SimScale supports the simulation of consumer products as diverse as washing machines, mobile phones, beverage containers, car seats, racing bikes, and many more, with plenty of different simulation types, including Structural Mechanics (FEM), Fluid Dynamics (CFD), Electromagnetics (EM), Thermodynamics, Acoustics, and Particle Analysis.

Customer Success

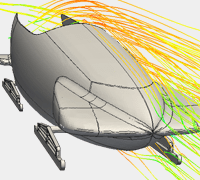

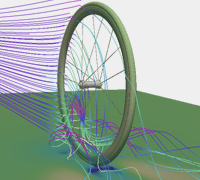

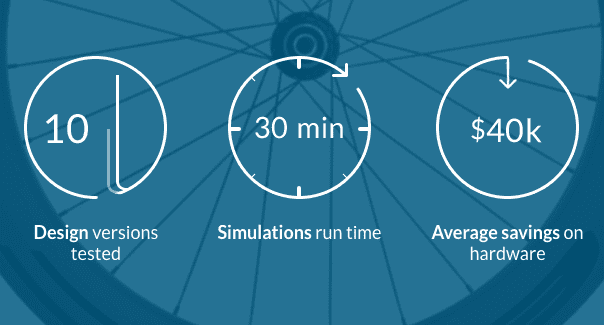

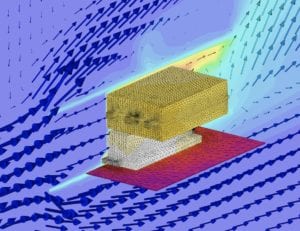

In this analysis, Tokyowheel wanted to ensure their carbon wheels were aerodynamic enough, so they ran multiple fluid flow analyses of strategically different wheel designs in parallel on SimScale. In 30 mins, they were able to test 10 designs and determine the most aerodynamic design profile, all the while saving no less than $40k on hardware.

Check out all the success stories of our customers in the Consumer Products industry, including EUROpack A.S. and more.

See All Stories

Sign up for SimScale

and start simulating now