Documentation

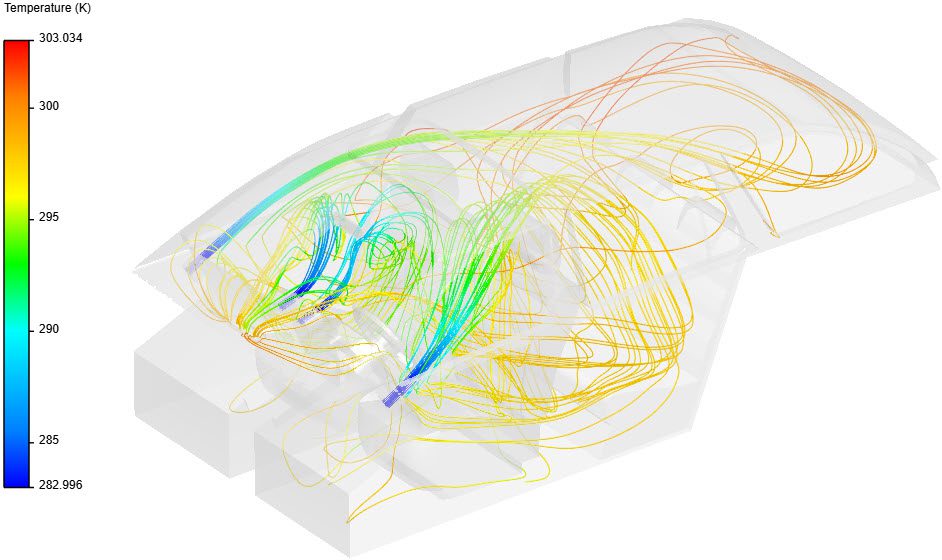

Convective heat transfer analysis can be used in cases where temperature changes in the fluid lead to changes in density. As a result, the fluid circulates under the influence of gravity.

To create a convective heat transfer analysis, the first step is to select the desired geometry and then click on ‘Create Simulation‘:

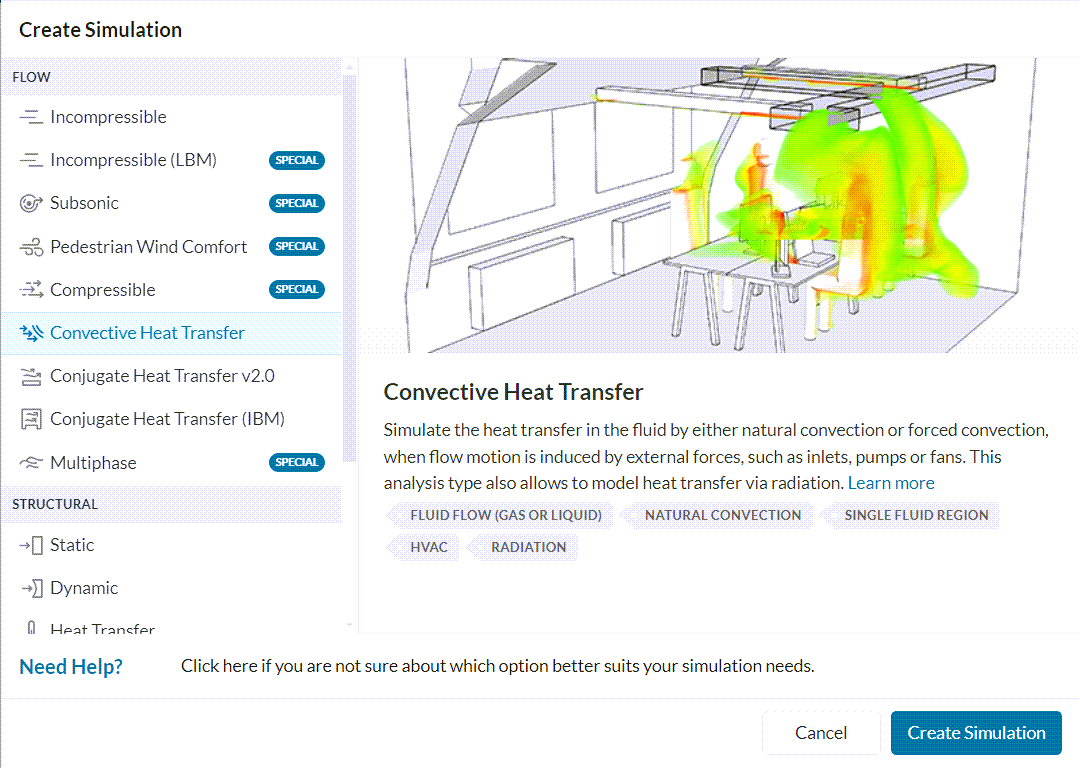

Afterward, a window with available analysis types appears as follows:

Choose the ‘Convective Heat Transfer’ type from the list and confirm your choice by clicking the ‘Create Simulation‘ button. The following simulation tree with the corresponding settings should appear:

To access the global settings, click on ‘convective heat transfer‘ in the simulation tree. In there, users can configure a series of parameters, namely:

For more information about each one of these entries, visit the global settings page.

The geometry tab contains the CAD model used for the simulation. Details of CAD handling are described in the pre-processing section.

Important

For convective heat transfer simulations, the solid parts should not be in the domain. Only the fluid domain is necessary.

In SimScale, it’s possible to use flow volume extraction operations to create a flow region and remove the solid parts from the domain.

Alternatively, it’s also possible to create the flow domain in your local CAD software.

Find more details on CAD preparation and upload here.

Under the model, gravity can be defined. If any passive species are being modeled, their diffusion coefficient can also be specified. Lastly, in case LES Smagorinsky or LES Spalart-Allmaras have been set as a turbulence model, their cutoff length can also be configured.

Find further information about the model tab here.

In the Materials tab, users should specify a fluid for the domain. For more information, please check the relevant documentation page for materials.

Initial conditions define the values which the solutions fields will be initialized with. They play a vital role in the stability and computing time of the simulation.

For a convective heat transfer analysis, the velocity, temperature, pressure, and passive scalar fields can either be initialized uniformly or separately via subdomains for each region.

For a complete list of parameters and initialization methods, check out this page.

Important

It is recommended to set the initial conditions close to the expected solution to avoid potential convergence problems.

Boundary conditions define the external input parameters for the simulation. For a complete list of boundary conditions and a description of how they work, make sure to check this page.

Some boundary conditions available in convective heat transfer simulations are supported in parametric experiments. Find an overview of parametric studies in this article.

Important

In case no boundary conditions are assigned to a face, by default it will receive a no-slip wall boundary condition with adiabatic condition (zero gradient) for temperature.

Furthermore, if radiation is enabled, these faces will also be modeled as grey bodies with 0.9 emissivity.

Under advanced concepts, you will find additional setup options, such as rotating zones, power sources, momentum sources, porous media, and passive scalar sources. Visit this dedicated page for more information.

Moreover, momentum sources, power sources, and rotating zones are supported in parametric experiments. Please visit this article for more details.

Note

It’s not possible to create rotating zones if radiation is enabled.

Numerical settings play an important role in the simulation configuration. When they are set correctly, they enhance the stability and robustness of the simulation. In most cases, the standard settings should be acceptable, and should not be changed without reason. Find further information here.

Note

SimScale uses its own version of OpenFOAM® solvers developed in-house.

The simulation control settings define the general controls over the simulation. In this tab, a series of variables can be set. For example, the end time and maximum runtime for the simulation can be defined.

For a complete overview of the parameters and their meaning, check this page.

Result control allows users to define additional simulation result outputs. These monitors are helpful to assess the convergence of a simulation. Amongst the available result controls, we have probe points and area averages.

Find more details about result controls here.

Meshing is the discretization of the simulation domain. It essentially means to split up a large problem into multiple smaller mathematical problems.

For a convective heat transfer analysis, the standard, hex-dominant, and hex-dominant parametric algorithms are available. For more information about meshes, make sure to check the dedicated page.

Last updated: April 26th, 2024

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now