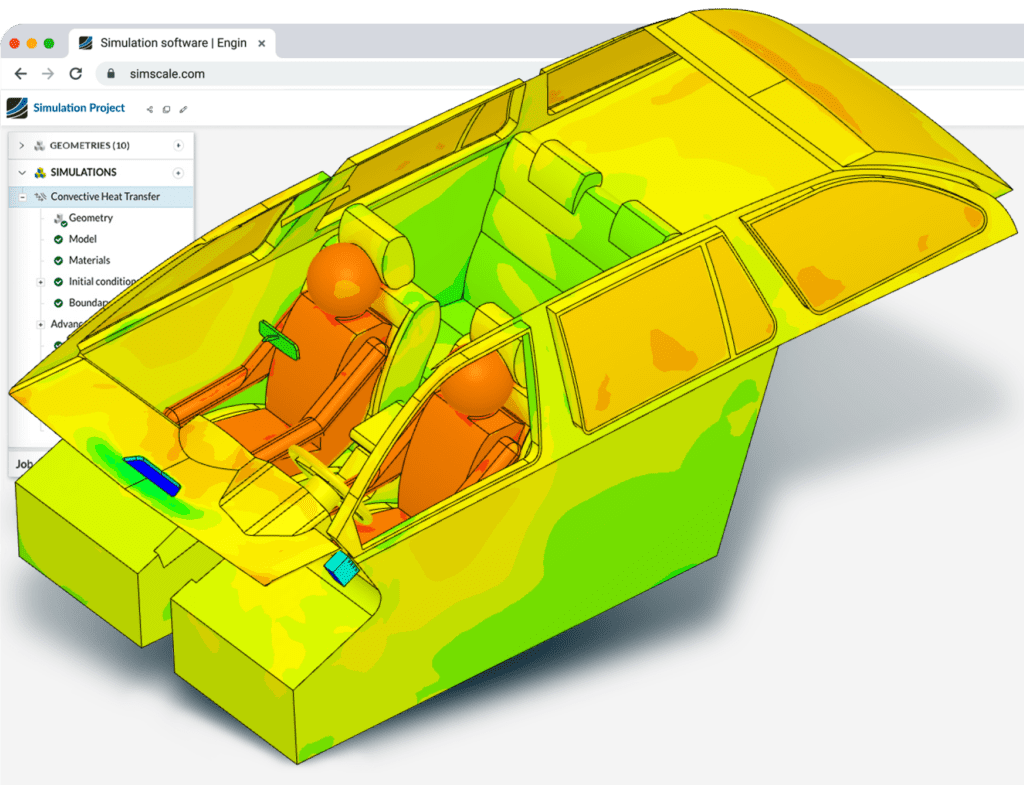

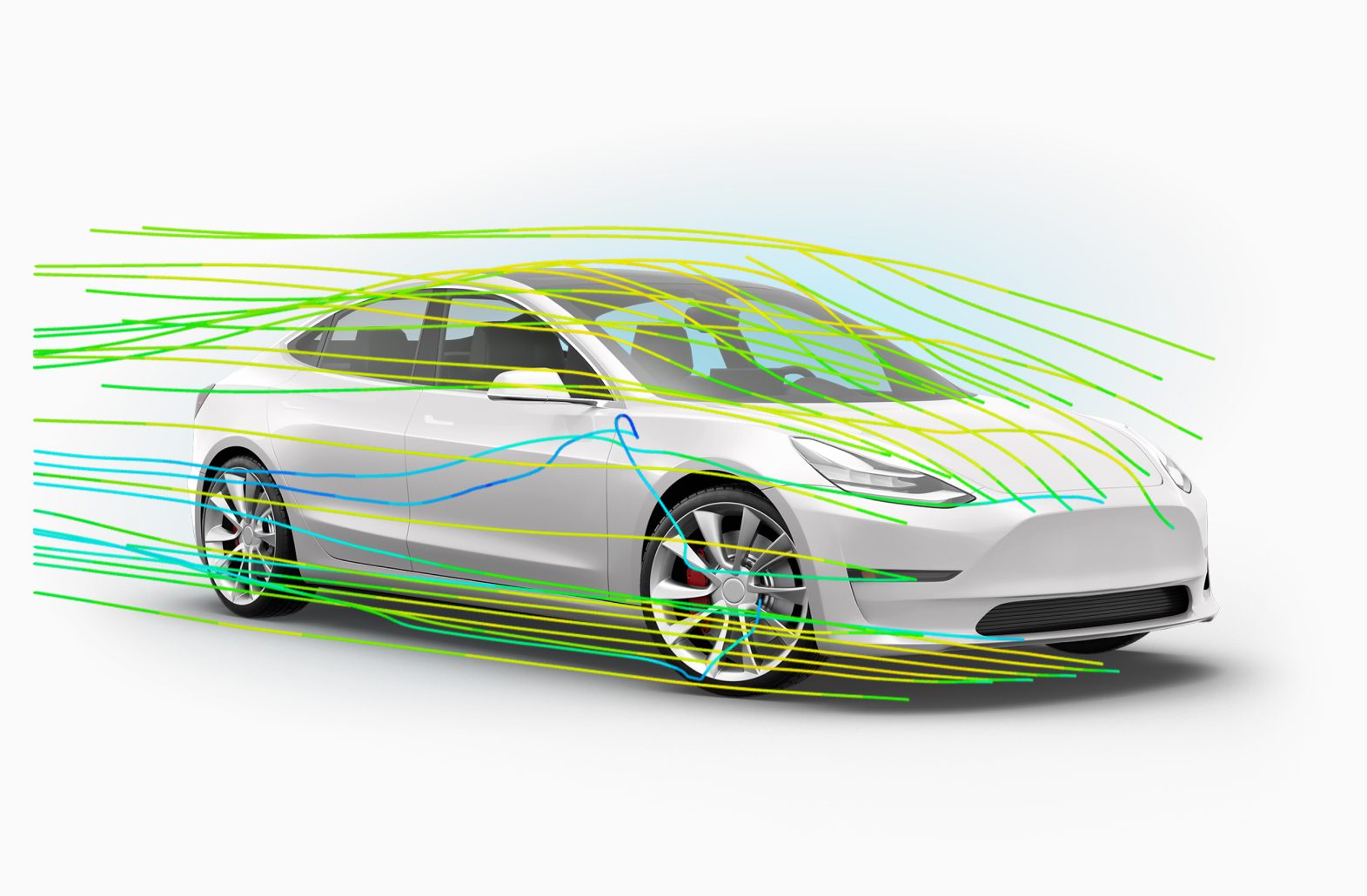

SimScale enables automotive engineering organizations to simulate earlier, broader, and faster and thereby deliver better vehicle designs earlier while improving engineering efficiency.

The automotive industry is transforming quickly towards more electrification, autonomy, connectivity, and sustainability. OEM and supplier engineering organizations need to accelerate new product introduction while lifting engineering efficiency on legacy products.

The rate-limiting factor for both is the cost and speed of making sound engineering decisions. The organizations that will thrive in this transformation are those that can rapidly iterate through design iterations via aggressive simulation use. Legacy simulation deployments are not built for this as they imply long simulation lead times and siloed use.

That’s where SimScale – a next-generation simulation platform – comes in. It dramatically reduces simulation lead time from weeks to minutes, enabling automotive engineering organizations to innovate faster while increasing engineering efficiency.

Cloud-native simulation’s HPC elasticity allows unlimited simulation size and simultaneous runs without the need to manage a data center. More simulations faster means compressed cycle times and faster innovation.

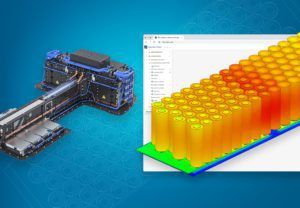

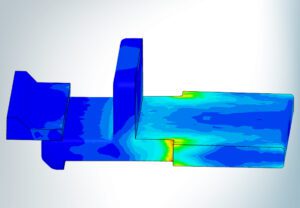

“Now we can innovate and test all the core functionalities (thermal, structural, and electrical) of the new high-voltage battery connector. We could not have developed this new product so fast without SimScale.”

Cloud-native simulation allows for decentralized simulation use while maintaining central quality control. Providing everyone safe and robust access to simulation becomes for the first time practically possible.

“Using SimScale in the early R&D stages of the product, we were able to fully leverage simulation capabilities into our product design process.”

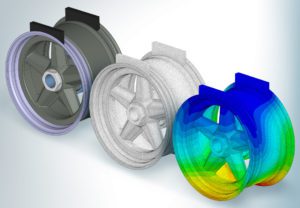

Next-generation engineering workflows such as generative, optimization, or AI do not work with legacy desktop data silos. Cloud-native simulation persists data in a way immediately accessible for AI, generative, or optimization workflows.

“The key advantage of using SimScale for us is to extract fast design insights at the early stages. We can then arrive at a final design faster and have more confidence when moving to the physical prototyping stage.”

Learn more about how you can optimize your automotive design process with SimScale and get industry insights for free.

Customer Success

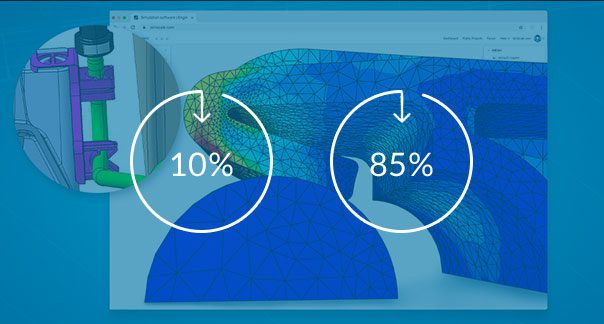

Using SimScale, ITW Automotive simulated the nonlinear static analysis of an anchor clip. With quick iterations and insights, they realized a 10% reduction in R&D costs and 85% reduction in insertion force.

Check out all the success stories of our customers in the automotive and transportation industry.

See All Stories

Sign up for SimScale

and start simulating now