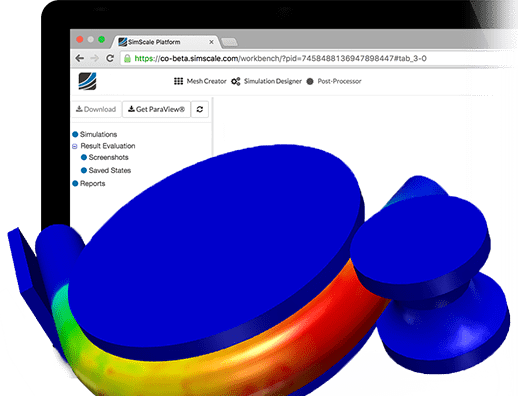

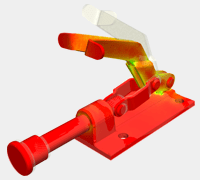

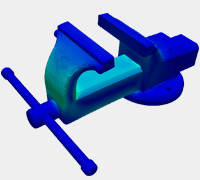

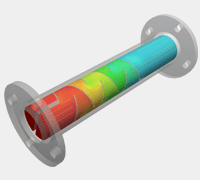

SimScale enables the rapid iterative design of complex manufacturing components and processes within your web browser. This toolset can be used by OEMs and end users to ensure quality, increase reliability, enhance safety, and ultimately reduce the cost of production.

With SimScale, manufacturing companies, OEMs and suppliers can virtually analyze and experiment with their processes and machines, massively reducing the time and costs associated with physical testing.

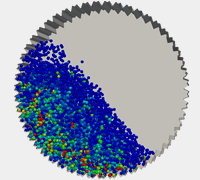

The rapid developments in technology, material science, and advanced manufacturing are changing the way global companies use market opportunities and create strategies to stay ahead of the competition. Along with innovative models, 3D printing, and analytics on customer preferences, simulation and computer modeling are part of the new era of innovation in manufacturing.

Optimized for a wide range of machines, tools, and processes, SimScale has been chosen by engineers worldwide to virtually test their designs and analyze multiple scenarios in less time with lower costs than physical prototyping.

Customer Success

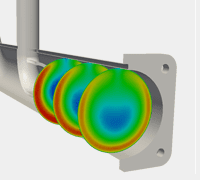

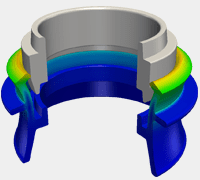

Carbomech simulated an air-bearing spindle using SimScale’s FEA analysis. They managed to get accurate results within an hour, cutting their physical prototype testing in half. Their ROI in using SimScale was significantly high, given that a spindle price is 3-4 times that of the SimScale subscription.

Sign up for SimScale

and start simulating now