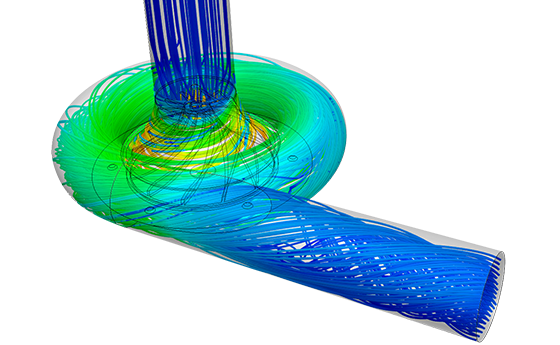

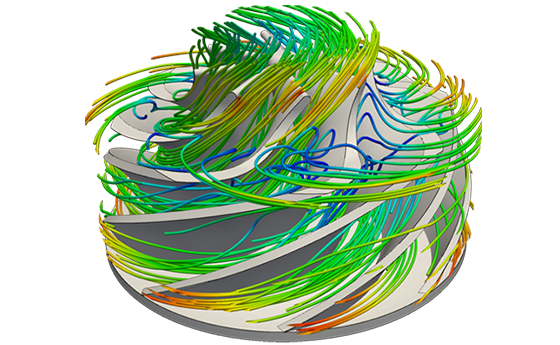

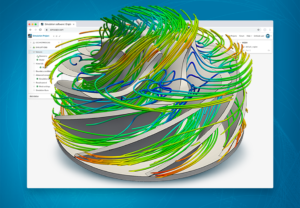

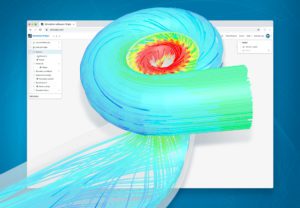

SimScale allows engineers and designers to simulate and optimize turbomachinery designs through CFD simulation

The SimScale Subsonic CFD solver is a multi-purpose analysis type specifically designed for turbomachinery, propellers, and more generally anything that rotates within a fluid. It includes a robust meshing strategy that produces an automated body-fitted mesh, plus a Finite Volume based solver optimized to handle a wide range of flow regimes including:

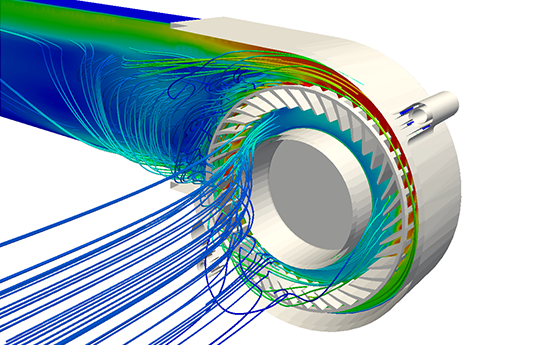

The Finite Volume-based CFD solver has segregated pressure-velocity coupling that uses a proprietary variant of the SIMPLE1 algorithm to solve the Navier–Stokes equations. It can simulate both incompressible and compressible flow, either laminar or turbulent in a single framework. Turbulence is modeled using the RANS equations with the k-epsilon turbulence model for closure and proprietary wall functions for near-wall treatment. Subsonic supports steady-state as well as full transient analysis. In full transient analysis, the fluid flow is modeled in a time-accurate manner and any rotating component in the domain is solved using the sliding mesh approach.

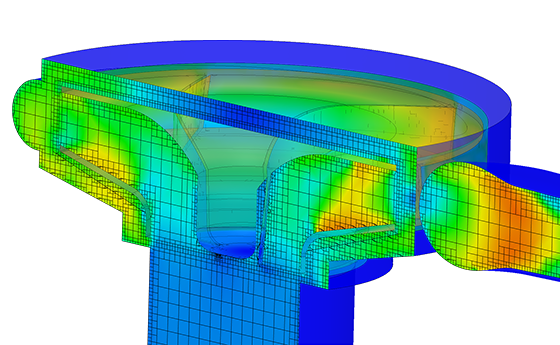

The Subsonic analysis type provides a very robust, automated binary-tree-based meshing algorithm producing hexahedral cells suitable for the underlying Finite Volume-based CFD solver. The meshing algorithm is highly parallelized for multiple CPU cores, reducing high-quality mesh generation times by considerable margins, and requires fewer cells to achieve the same level of accuracy and rapid solver convergence. Another feature is the automatic generation of optimal mesh interfaces between the rotating and stationary components of the system being simulated.

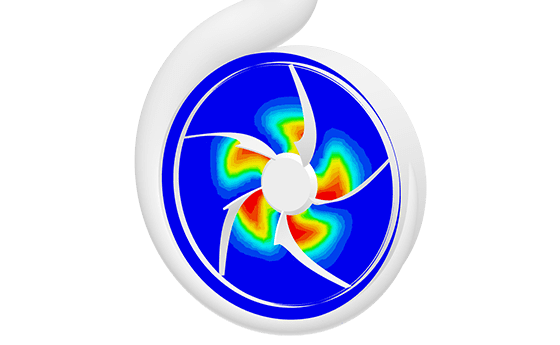

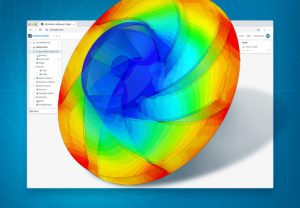

Cavitation is the formation of vapor bubbles in low-pressure/high-velocity regions of liquids. Cavitation reduces propeller/impeller performance & can even lead to physical damage to the rotating part and structure in close proximity. This is because when the cavitation bubbles collapse they generate shock waves that create mechanical vibration (& acoustic noise). This is an important real-world effect that SimScale factors into the CFD simulation of pumps, water turbines, and marine propellers, or any rotating machine immersed in a fluid. The SimScale subsonic multiphase CFD solver computes the space occupied by each phase (volume fraction) and cavitation results are shown as the volume fraction of gas present (in the liquid).

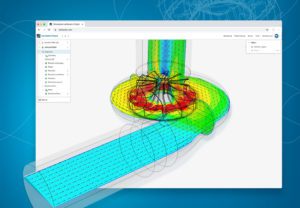

Turbos, pumps, and fans are fundamentally mechanical machines used to generate fluid flow. As the flow rate increases, the pressure drop between the inlet and outlet of the machine/system increases, which affects the performance of the machine/system. Pump and fan manufacturers provide pump/fan curves that describe the relationship between static pressure, power requirement, rotational speed, and efficiency values per-flow rate conditions. This information is very important for engineers who need to ensure the correct size of fan/pump is installed to achieve the desired flow rate/cooling conditions in the system. SimScale allows engineers to directly enter the manufacturer’s fan/pump curves data as a table, this is good news for engineers using off-the-shelf pumps/fans. However, for those designing new fan/pumps, SimScale can also calculate pump/fan curves for a design by running parametric studies/sweeps that solve for a range of pressure drop/flow rate scenarios of the design. The highly parallelized and cloud-optimized algorithms allow a parametric study to run in nearly the same time as a single data point run!

Cloud-optimized solvers make it possible to run transient CFD simulations in a fraction of the time taken by traditional CAE. For example, a full transient simulation for a centrifugal pump with a mesh size of nearly 0.6 million cells takes under 20 minutes. The same simulation in traditional CFD tools would take at least 12 hours.

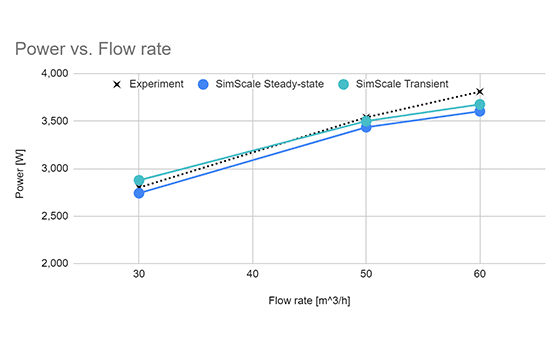

To establish the accuracy and reliability of the transient solution, we have validated the solver against a range of standard benchmarks. The chart shows the comparison of power vs. flow rate for a centrifugal pump. The results from the transient analysis are a very close match with the experimental results, far closer than the steady-state MRF method. Also, a mesh independence study for this case resulted in a model size of about 0.6 million cells and a full transient run for one flow rate took just 18 minutes to complete.

Customer Success

Hazleton Pumps used SimScale to obtain fast and accurate fluid flow and performance assessments for their pump designs. They realized 100% time savings and $10K reduction of HPC costs.

Check out all of our turbomachinery success stories including Designcraft, Guerriero Romani, and more.

See All Stories

Learn how to use cloud-native engineering simulation to design energy-efficient water pumps.

Learn how to use CFD on a Francis turbine to obtain the turbine performance curve within minutes, including transient and cavitation effects.

A webinar demonstrating the optimization of a KSB heating circulator pump, covering parameterization and computing hundreds of design of experiments (DoE) runs using the shape optimization tool CAESES.

Learn how you can quantify the effect of cavitation on pump performance in minutes thanks to the practically unlimited computational power offered by engineering simulation in the cloud.

Yes. It is possible to factor in cavitation in SimScale i.e. The formation of vapor bubbles in when the pressure in the domain falls below the vapor pressure of the working liquid. Cavitation is a feature that can be enabled at the Create Simulation top level menu in SimScale, in the same dialog box where the user chooses steady state or transient simulation.

Yes. SimScale provides a conjugate heat transfer solver that simulates heat transfer from the fluid domain to the mechanical parts, or visa-versa where heat is transferred from the structure into a fluid. In this regard SimScale can also be used to simulate heat exchangers.

SimScale’s Subsonic analysis type can handle transonic and supersonic flows and as such, there is no limit of the turbine RPM.

For turbomachinery & flow control applications, SimScale uses a proprietary solver that is specifically tailored for such applications, it is based on the Simerics solver, and available within the SimScale Subsonic analysis type. SimScale also offers other CFD analysis types that are also suitable for turbo machinery rotating machinery and flow control applications, these are based on a proprietary version of OpenFoam.

Yes. SimScale supports one way coupled fluid-structural simulations. So in the case of a wind turbine you pass the CFD dynamic loads into a structural simulation to look at the stress and deflection of the blades.

SimScale provides a rotating wall and a rotating zone approach. Rotating walls are applicable to cylindrical surfaces which rotate. The Rotating zone approach is commonly used to simulate rotors and impellers that rotate on a fixed axis. There are two flavors of rotating zones: Multiple Reference Frames (MRF) is used for steady state; and Sliding Mesh technique is used for fully

transient simulations. Sliding mesh is computationally more expensive than MRF, as it takes into account all transient effects.

Yes. It is possible to simulate fluid viscosity as a function of temperature in Subsonic analysis type, when compressible mode is enabled.

Yes, it is possible to simulate Non-newtonian fluid flow in all the OpenFoam based solvers of SimScale. This capability is also on the Subsonic solver roadmap for a future release.

Cavitation is shown in post processing as total gas volume fraction, so you can see exactly the regions where cavitation is most likely to occur.

SimScale’s turbomachinery solver, Subsonic, can be used to run multiple flow rates simultaneously to automatically generate a pump/fan curve.

Sign up for SimScale

and start simulating now