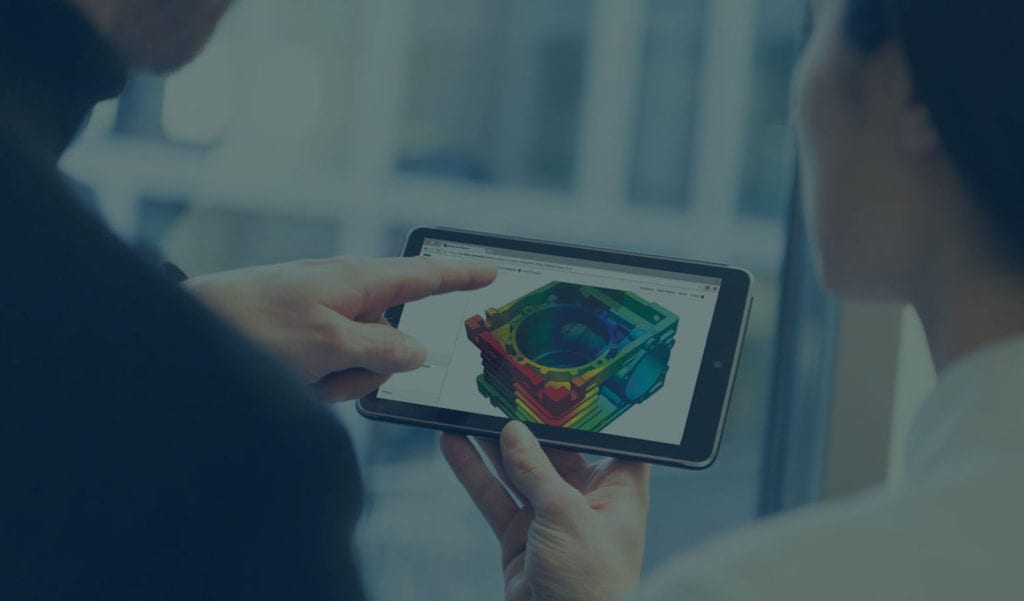

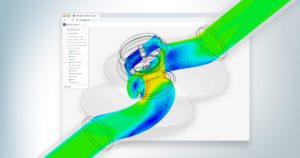

SimScale enables your engineering team to simulate every aspect of valve performance simply from their web browser. Bring better-performing valves to market faster while simultaneously reducing your R&D expenses on hardware and lab testing.

Staying competitive requires engineers to constantly innovate and find new ways to improve their designs while reducing development costs and time to market. Computer-aided engineering (CAE), also called engineering simulation, is becoming the industry standard for developing valves better, faster, and cheaper. Using cloud-based CAE with SimScale, engineers worldwide are performing computational fluid dynamics for testing and optimization of valves for all sorts of different applications. The SimScale platform enables you to test several design versions.

With CAE, you can identify where you have material, that is unnecessary and weight that could be saved. For every application where a valve is moving in any way, weight reduction is of importance, as cars for example always get lighter to save fuel. Lighter valves take a small, but valuable part in this process. To learn more, download our pump and valve design guide.

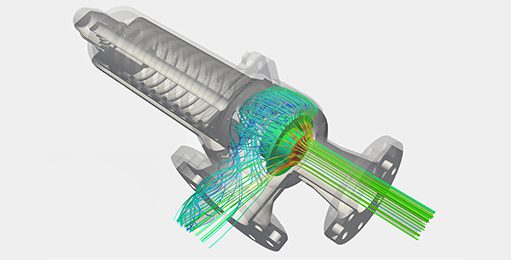

Cavitation is a side effect that many valves have because they were not optimized for a minimum amount of cavitation. Gas bubbles in the valve make the valve more ineffective and can lead to a failure of the application attached after the valve. Reducing this effect can be reached with the SimScale simulation platform.

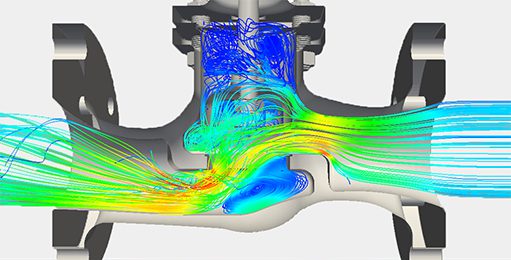

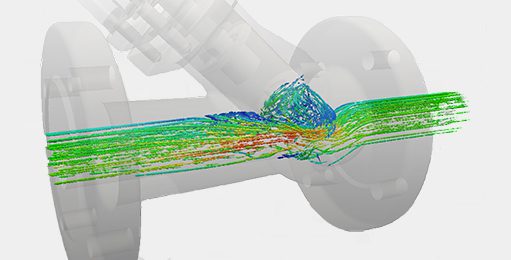

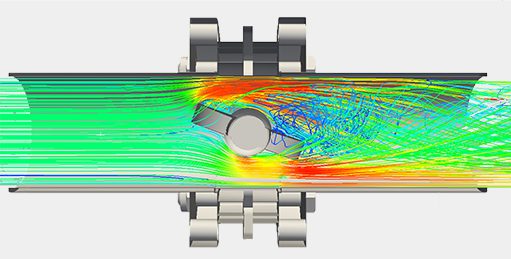

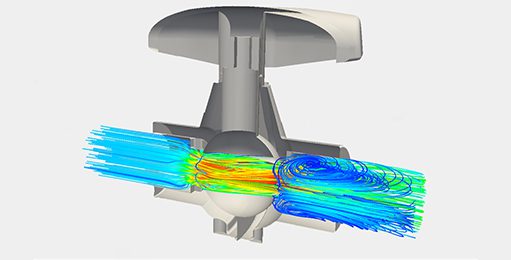

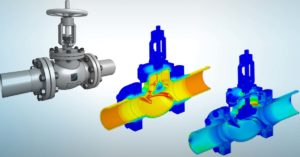

Different pressure regions within a valve lead to stresses that the valve does not need to be exposed to. It could potentially reduce the durability of the valve. Computational Fluid Dynamics helps identify these pressure differences and eliminate them. With this webinar, discover how to calculate the pressure drop across a valve with online CFD.

Optimizing the flow through a valve leads to a higher volume per time that can pass the valve. This is interesting for applications where the physical space for the valve is limited. The valve needs to be as small as possible without limiting the volume that can pass. This study of an EGR valve webinar shows how to optimize designs of exhaust systems and its components using CFD.

Worst-case scenarios are not to be tested with a physical object. To make sure that there is no harm to humans, even if all safety measures fail, worst-case scenarios should be simulated virtually.

Customer Success

Diinef used CFD simulation to improve their hydraulic motor valve designs. They were able to pressure drop by 80% and saved $40k on hardware.

Sign up for SimScale

and start simulating now