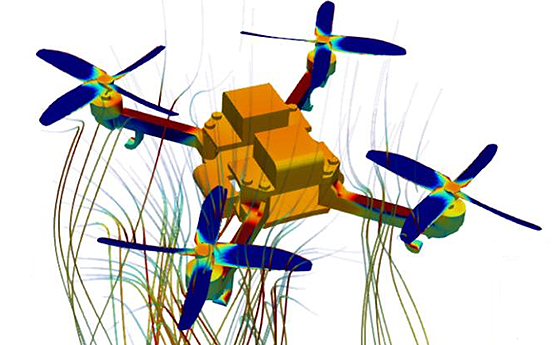

SimScale enables engineers and designers to design, analyze, and optimize multiple aspects of turbomachinery machines with fast and accurate simulations.

SimScale provides high-fidelity engineering simulation tools for propeller, fan, compressor, pump, and turbomachinery applications that are both technically and economically accessible for designers and engineers, at any scale, in the cloud.

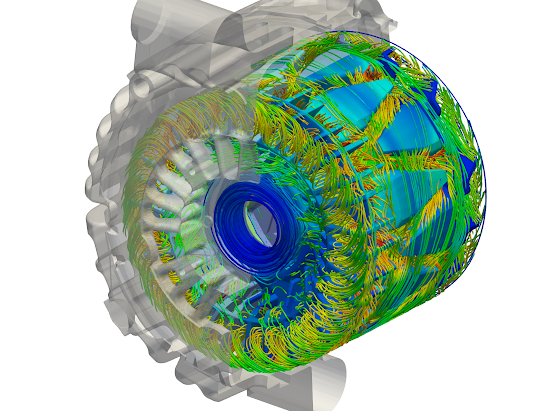

Our innovative cloud-native simulation platform lets you explore, test, validate, and optimize your product ideas and designs through the use of computational fluid dynamics (CFD), heat transfer, and structural dynamics analysis. The advanced physics solvers allow designers and engineers to study & optimize pressure drop and force behavior, evaluate fluid flow patterns, and minimize (or even leverage) cavitation effects.

By deploying simulation early in the product design process turbomachinery & pump engineers can ensure that they meet and in most cases exceed their design validation requirements. Simulation provides detailed insights into performance characteristics, allowing engineers to identify design strengths and weaknesses in a virtual prototype, avoiding costly physical testing & prototype rework.

Furthermore, the resultant time & cost savings from simulating early and often allows engineers to explore more of their ideas, sparking innovation which often leads to IP and a competitive edge.

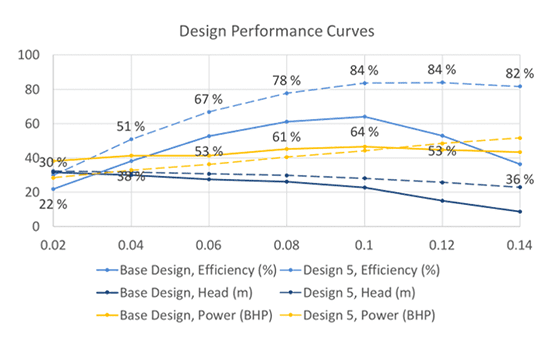

Enables rapid design iterations and automated performance curve generation (pump curves & fan curves).

SimScale meets and in many cases exceeds the accuracy and speed of traditional CAE simulation tools. Note that speed does not compromise accuracy! Test models have achieved 2-3% accuracy within 15 minutes.

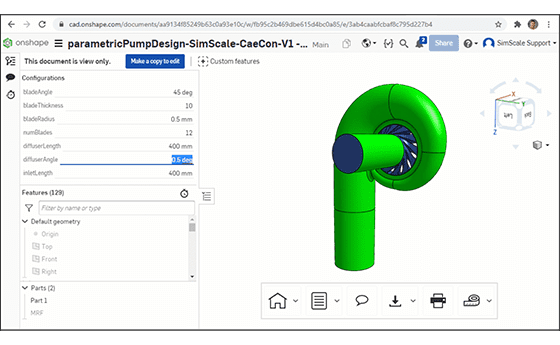

Turbomachinery simulations and workflows are usually complex —SimScale takes away the complexity and replaces it with an intuitive, automated, and robust UI which reduces person-hours required for simulation and also makes it accessible to non-experts/designers.

Changing geometry and simulating new designs quickly and seamlessly is generally a big ask from turbomachinery & pump engineers. CAD Associativity makes it easy for users to quickly simulate different design iterations imported from their CAD system. This feature allows geometry to be swapped retaining load and boundary condition assignments and is available for OnShape and Solidworks. Additionally, the SimScale API facilitates bi-directional coupling with many popular CAE design optimization tools, including ESTECO modeFRONTIER & VOLTA.

Fluid dynamics, thermal, and structural physics simulation are all on the same platform, enabling turbomachinery engineers to investigate rotordynamics, mechanical stress, deformation, and heat transfer in addition to fluid dynamics.

Customer Success

Hazleton Pumps used SimScale to obtain fast and accurate fluid flow and performance assessments for their pump designs. They realized 100% time savings and $10K reduction of HPC costs.

Check out all of our turbomachinery success stories including Designcraft, Guerriero Romani, and more.

See All StoriesSign up for SimScale

and start simulating now