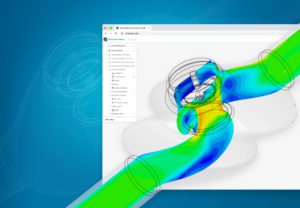

SimScale allows you to simulate and optimize various performance characteristics of valves and other flow control equipment

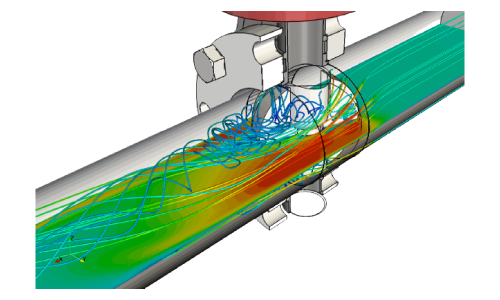

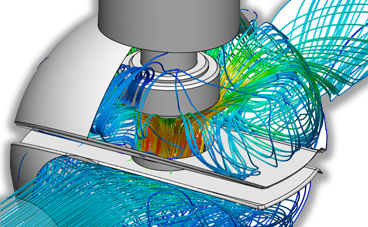

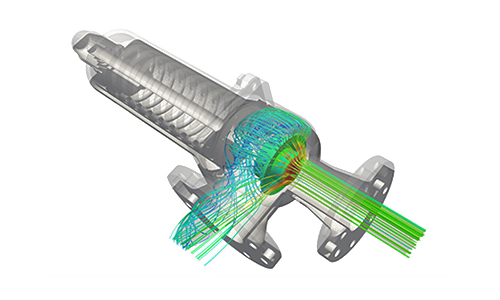

Optimizing the flow through a valve leads to a higher volume per time that can pass the valve. This is interesting for applications where the physical space for the valve is limited. The valve needs to be as small as possible without limiting the volume that can pass.

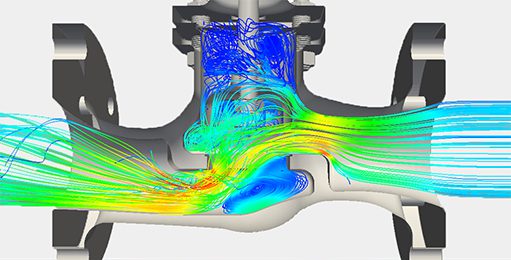

A non-ideal flow path through a valve can cause the liquid or gas to separate and create artificial blockages that increase the pressure loss across the valve. SimScale allows to simulate the flow behaviour, identify problematic areas and reduce the pressure drop across the valve.

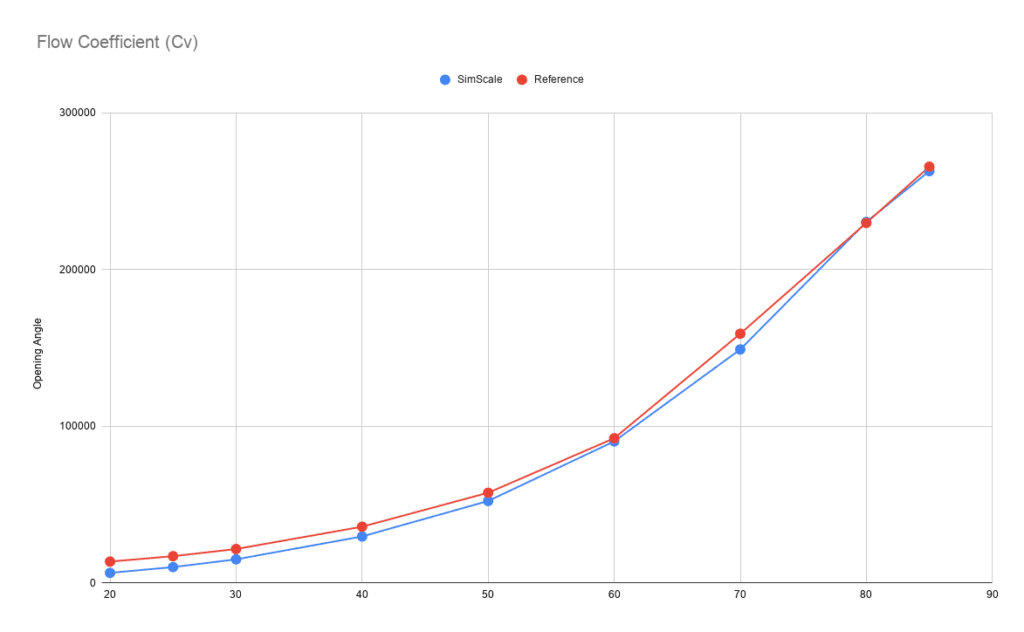

The valve flow coefficient, Cv, is a valve’s capacity to allow fluid to flow through it. It is a function of the pressure drop across the valve, flow rate and specific gravity of the fluid. Calculating and visualizing a Cv curve enables engineers to select the right valve sizing for a particular application. SimScale allows to simulate multiple opening/closing positions simultaneously and hence automatically plot full valve performance curves within minutes.

When strong pressure waves travel through a pipe system they can cause a tonal noise not unlike a hammer hitting a wall. This effect is what is generally referred to as a “water hammer”. A “water hammer”, or more generally fluid hammer, occurs when a fluid that is in motion is forced to stop or change direction suddenly, affecting its momentum. If a valve closes too quickly or suddenly within a pipe system, this creates a surge of compression-suction pressure. In mild cases, this will lead to noise or vibration; in major cases, it can lead to total pipe collapse.

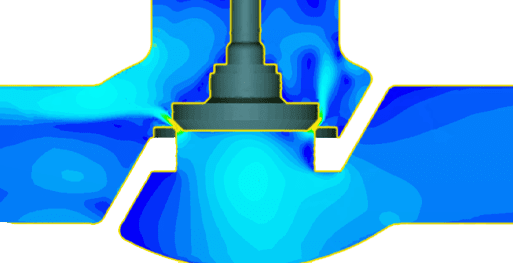

Cavitation is a side effect that a lot of valves have because they were not optimized for a minimum amount of cavitation. Gas bubbles in the valve make the valve more ineffective and can lead to a failure of the application attached after the valve. SimScale allows to identify and mitigate flow regions with high cavitation risk.

“Choke” occurs in a system when flow velocity increases to such an extent that it matches the speed of sound. This causes a shockwave which decelerates the flow rate and can cause a blockage in the system. Choke appears most commonly in gas systems, and can generally be avoided with a proper aerodynamic analysis. CFD simulation is an excellent tool to check for regions of high speed, and through these results, optimize the geometry.

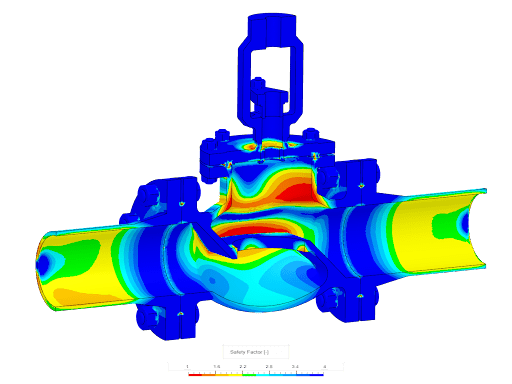

Valves should need little material and space while being able to withstand internal pressure and thermal loads. SimScale helps to navigate this engineering trade-off by identifying regions of high and low stress concentrations that in turn inform design decisions.

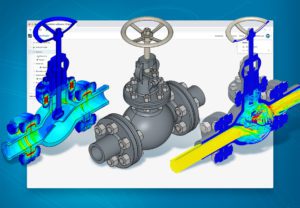

Learn about CAD integration, intuitive fluid flow (CFD), and structural (FEA) simulation workflows with a live demo covering the fluid flow within a globe valve and structural response to the fluid pressure. Simulations will be run in the SimScale multiphysics engineering simulation platform.

Learn how CFD engineers solve shape optimization problems with engineering simulation in the cloud.

Learn the optimization process for a novel Tesla Valve design targeted to be used in pulsating heat pipes with its aligned inlet and outlet.

Sign up for SimScale

and start simulating now