SimScale enables marine engineers and designers to test, validate, and optimize their designs through CFD, FEA, and thermal analysis.

Being an integral part of the design process, from concept to product release and certifications, Computer-Aided Engineering is an indispensable tool in the Marine industry. Industrial applications are highly demanding in single-phase as well as multiphase CFD techniques. Several rapid simulation techniques have been developed, specifically to enhance the integration and performance of CFD and FEA tools in the marine industry. SimScale’s cloud-based tools are recurrently applied to solve problems in the domains of computational fluid dynamics, structural, conjugate heat transfer, and thermal simulations.

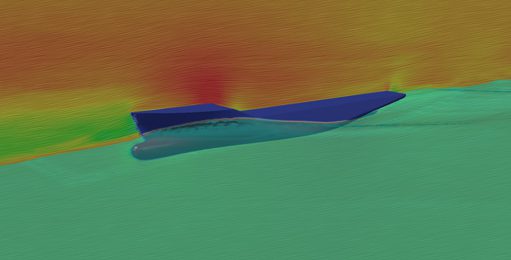

The ship hull resistance is the primary factor influencing fuel efficiency in ships. The shape optimization of the hull to predict and reduce resistance is hence indispensable in the shipbuilding process. SimScale provides a 100% cloud-based simulation platform to help with this process. The KCS ship hull, widely used as a benchmark in the shipbuilding industry, has been successfully simulated with SimScale’s CFD solution.

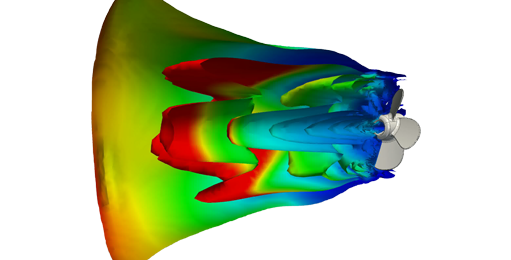

The propulsive efficiency of ship propellers can be significantly enhanced with CFD. With SimScale’s cloud-based CFD tool, the propeller performance can be quantified and improved, end-to-end, in the web browser. Furthermore, SimScale’s cavitation model can robustly model the effect of vapor bubbles in incompressible liquid flow.

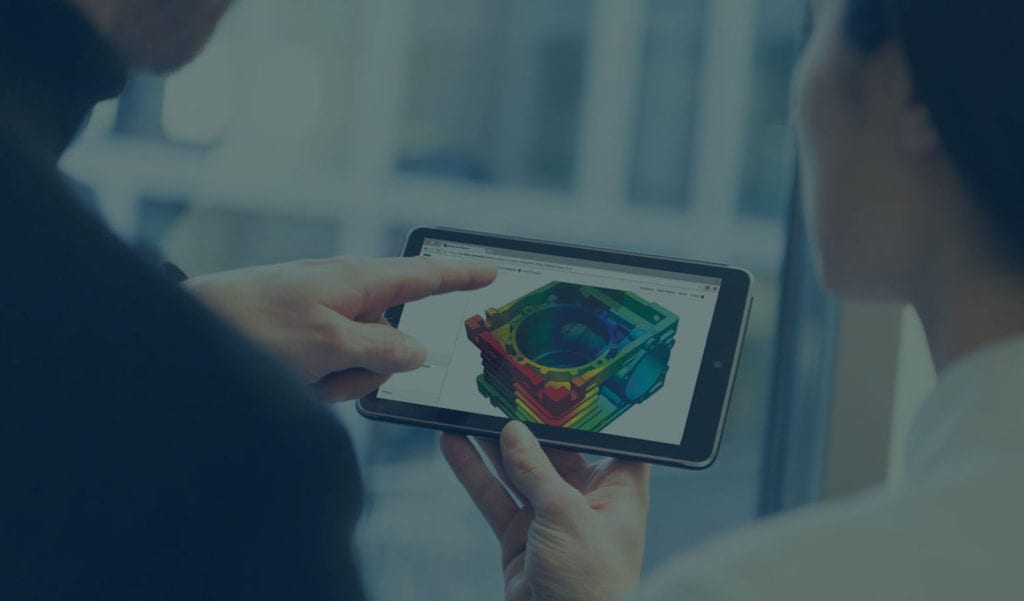

CAE enables you to predict and optimize the performance of a new ship. Several design iterations can be rapidly verified and compared via virtual prototyping and simulation. With SimScale’s workflow, you have an end-to-end process, everything happening in the web browser.

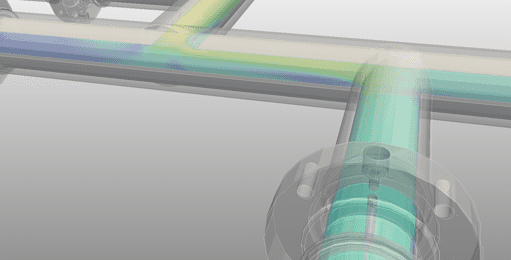

Submarine pipelines, often connecting two continents for oil or water supply, are highly reliant on fluid and structural simulations to alleviate points of failure. With SimScale’s FEA and CFD capabilities, high-fidelity simulation results can be directly implemented into the early design as well as in-operation maintenance processes

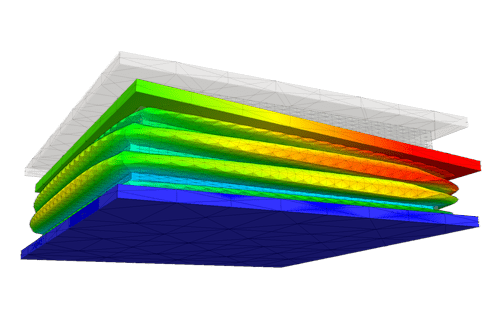

The bearing loads on a bridge are crucial to its structural integrity. With SimScale’s nonlinear FEA capability, the loads can be accurately quantified.

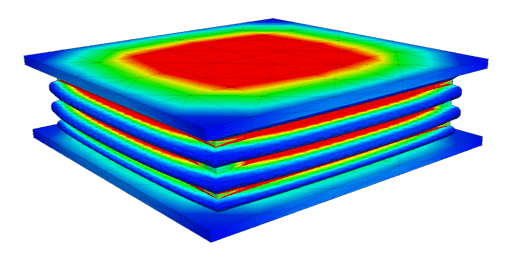

Because bridge elastomeric pads are crucial to safe and cost-effective bridge design, they are extensively prototyped and tested before they are used in production.

Customer Success

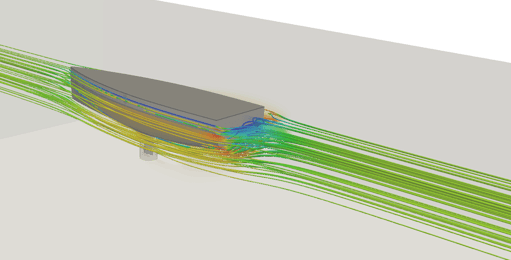

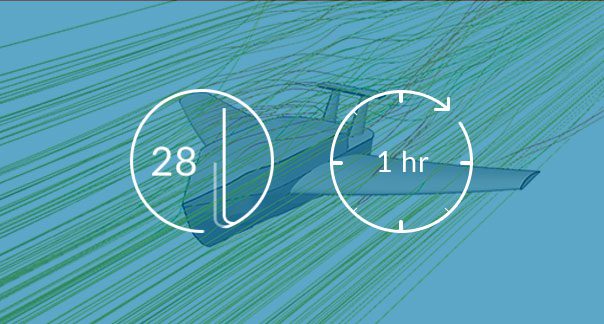

Brainbox used SimScale to study the behavior of a wing-in-ground (WIG) effect for a marine craft using external aerodynamic flow analysis. They were able to run 28 simulations in parallel and single-phase simulation results averaged an hour or less.

Sign up for SimScale

and start simulating now