Documentation

The aim of this project is to demonstrate the validity of SimScale’s CHT v2.0 and CHT IBM solver by performing a conjugate heat transfer analysis of a battery pack and comparing the following parameter:

The simulation results of SimScale were compared to the results presented in [1]. Code Verification is also carried out by comparing the SimScale results to Fluent results.

Note

The validation case consists of two geometries Battery_Pack and Battery_Pack_v2. Both are essentially same however Battery_Pack_v2 is devoid of redundant face splits as compared to Battery_Pack.

The geometry can be seen below:

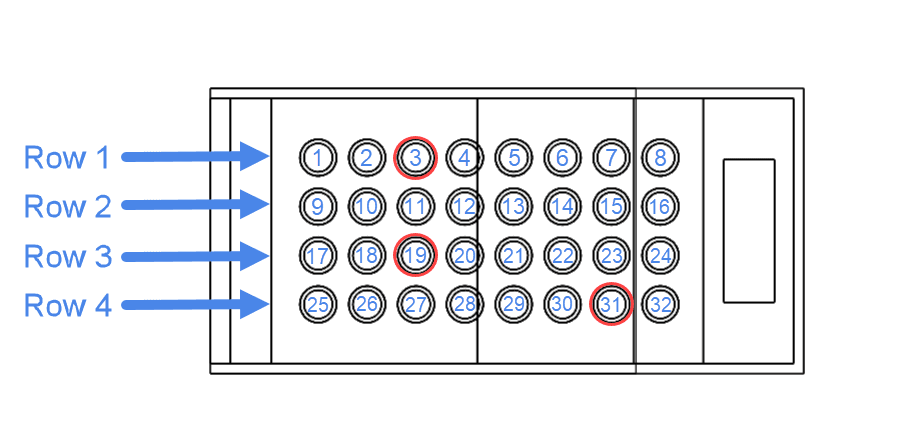

It represents a 1:1 model reverse-engineered from images in the publication. The battery pack consists of 32 (8×4) cell configuration.

The thermocouple location on the leeward side of the cells has been used for validating the conjugate heat transfer solver:

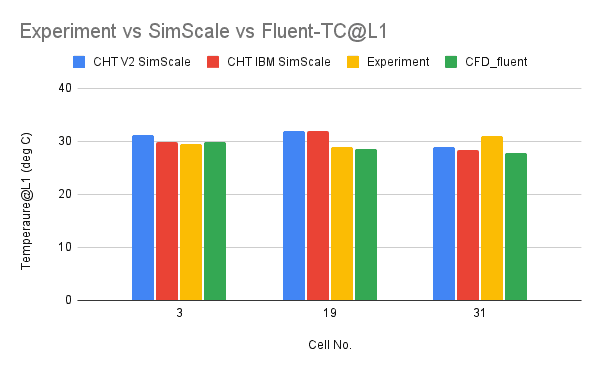

The thermocouple readings from cells 3, 19 and 31 have been used for the comparison:

Tool Type: OpenFOAMⓇ

Analysis Type: Compressible, steady-state analysis with the CHT v2.0 and CHT IBM solver.

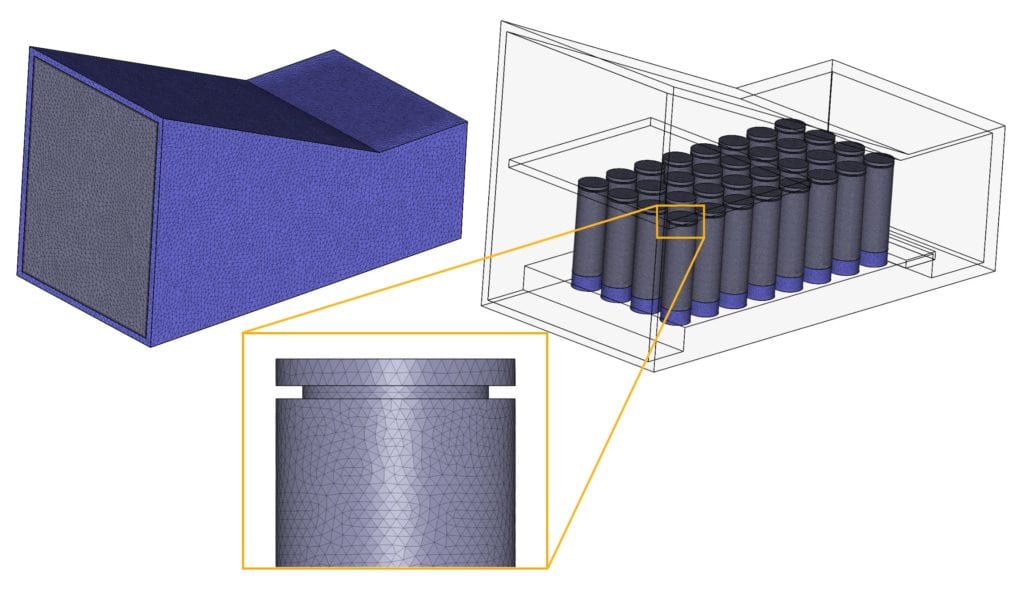

Mesh and Element Types:

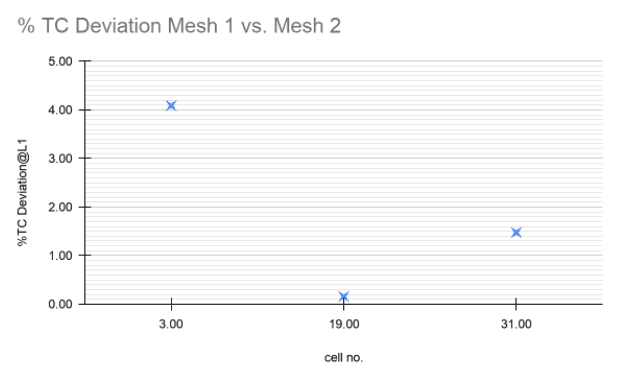

The Standard mesher algorithm with tetrahedral and hexahedral cells was used to generate the mesh. A mesh sensitivity analysis has been carried out to determine the dependence of the CHTv2 solver temperature predictions on the mesh, while using lead as the material of the cells:

| Mesh Type | Number of cells/nodes | Temperature@L1-cell3 [\(°C\)] | Temperature@L1-cell19 \([°C]\) | Temperature@L1-cell31 \([°C]\) |

| Mesh 1 | 3.6M cells, 1.1M nodes | 29.535 | 31.065 | 26.816 |

| Mesh 2 | 11.2M cells, 3.5M nodes | 30.794 | 31.114 | 27.218 |

| %TC deviation (Mesh 2 – Mesh 1) | 4.089 | 0.157 | 1.477 |

Maximum temperature deviation of 1.2 \(°C\) (~4.1%) between Mesh 1 and Mesh 2, was observed at leeward side of cell 3. In the following figure the percentage of temperature deviation in degrees Celsius (% TC) at measurement location L1 is displayed for three different mesh configurations as well:

In order to estimate the physical properties of the cells, a material sensitivity study has also been carried out, using three different materials:

Comparing L1 temperatures for the three materials, according to the diagrams below, aluminium cells show the closest match:

Hence, based on the material and mesh sensitivity analyses, aluminum cells and “Mesh 2” have been used for the final validation using CHT v2.0 analysis.

For CHT IBM analysis the IBM solver creates a Cartesian mesh that does not resolve every part separately as in a body-fitted meshing approach, but refines the Cartesian grid towards geometrical and topological details and immerses the geometry into it. The detailed treatment is done on the solver level instead.

Fluid Material:

Solid Materials:

Boundary Conditions:

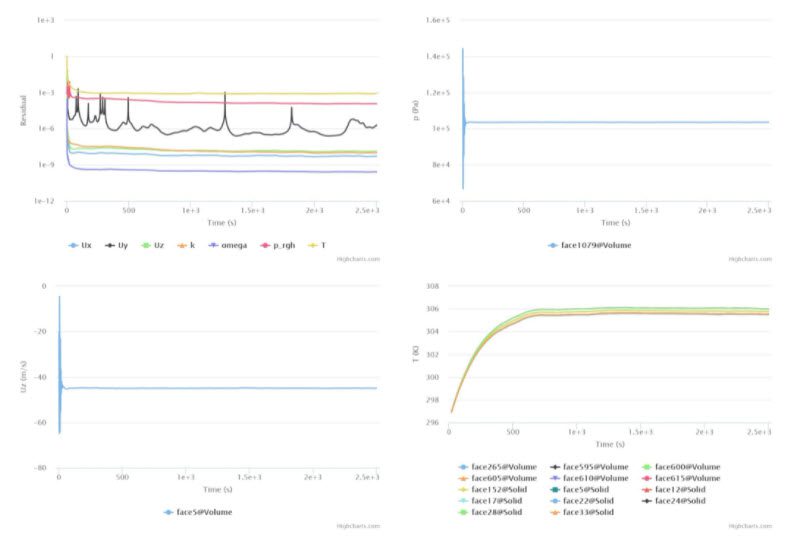

Convergence below 1e-3 has been achieved. Calculated physical quantities such as inlet pressure, outlet velocity, and cell average temperatures have also been allowed to converge to stable values:

The final temperature values are displayed in the following table:

| Cell No. | CHT V2 SimScale\([°C]\) | CHT IBM SimScale\([°C]\) | Experiment \([°C]\) | CFD_fluent \([°C]\) |

| 3 | 31.22 | 29.42 | 29.42 | 29.92 |

| 19 | 32 | 31.86 | 29.01 | 28.52 |

| 31 | 28.85 | 28.45 | 30.99 | 27.78 |

Comparing CHTv2 solver predictions to thermocouple readings@L1, temperature deviations of:

The temperature deviations predicted from the CHTv2 solver are in good comparison with ANSYS Fluent and the experimental data.

There are some minor deviations and the reasons could be:

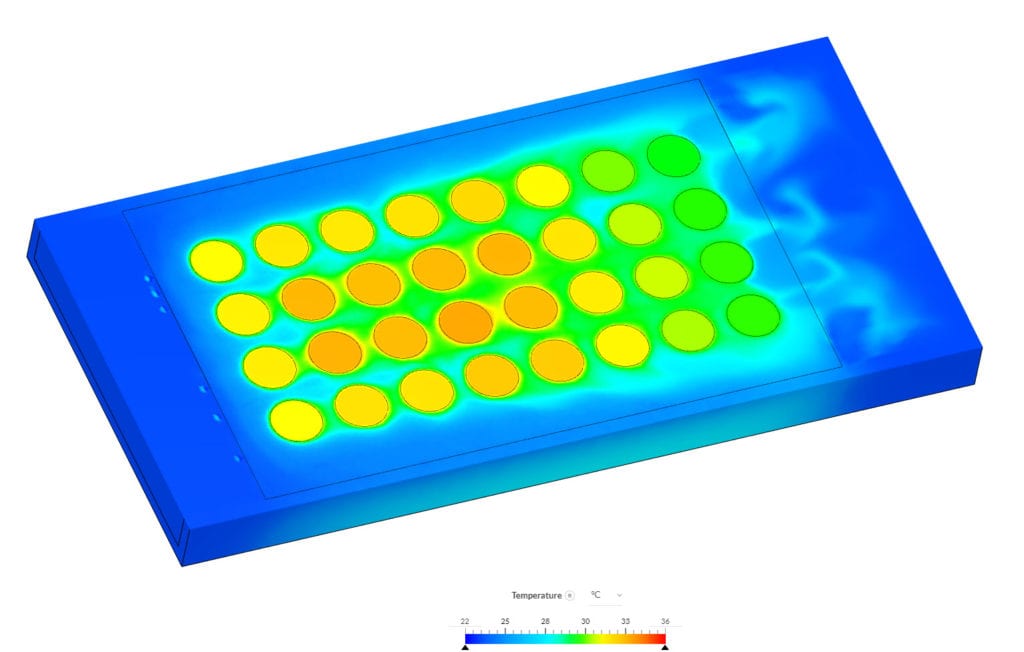

In the following image, the temperature distribution across the flow domain indicates the heat transfer from cells to the air inside the battery pack. The cutting plane displayed is normal to the z axis:

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: April 9th, 2024

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now