Explore thousands of design decisions in seconds with the world’s first AI-native simulation platform.

Helping the world’s best teams to engineer the irreplaceable

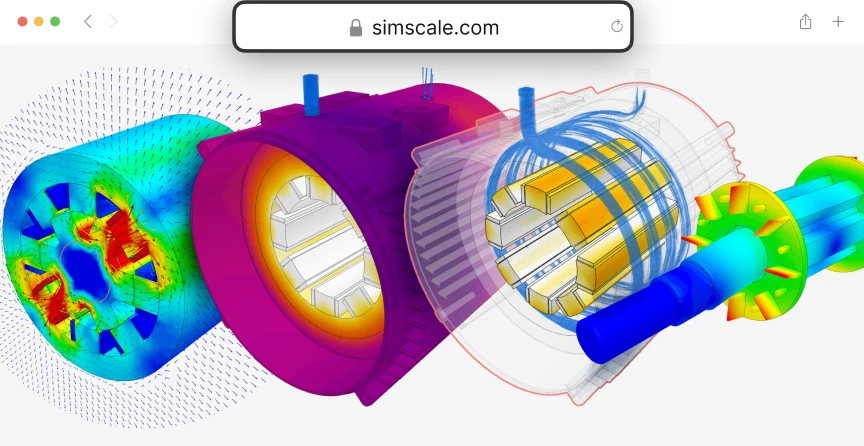

SimScale’s AI-native cloud platform unlocks engineering velocity through broad, early, and instant simulation.

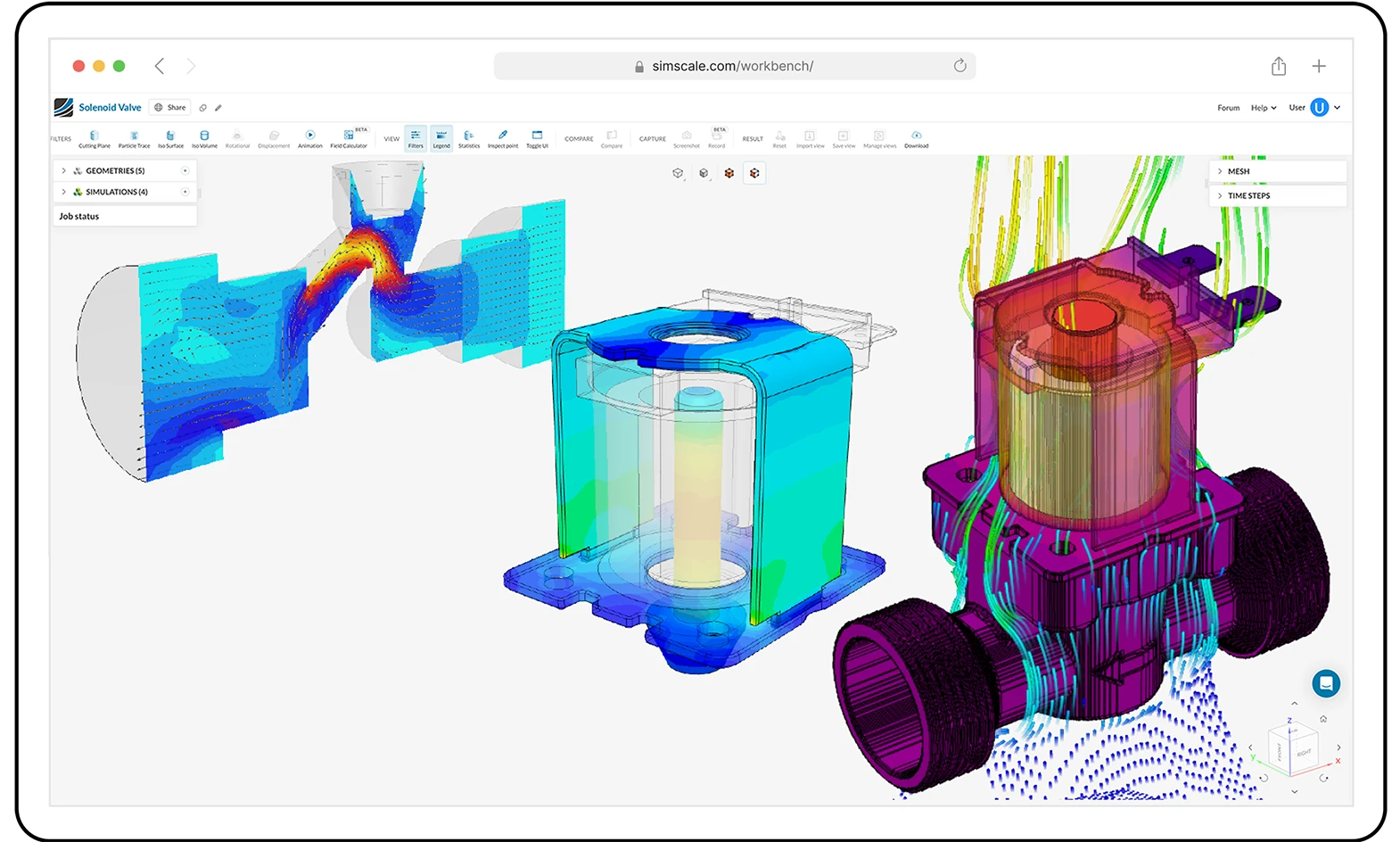

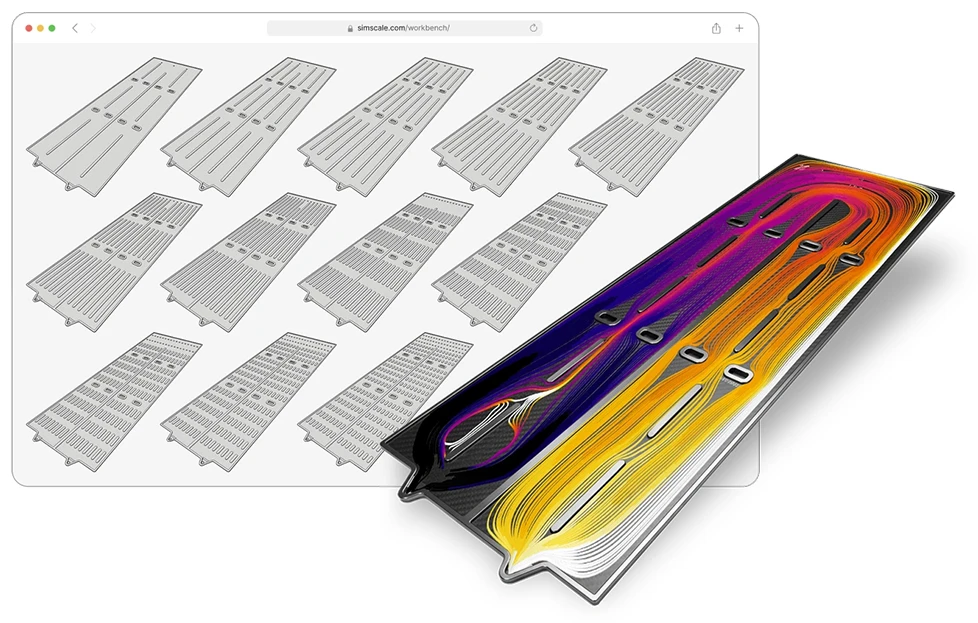

SimScale puts powerful multiphysics simulation in every engineer’s hands via an easy, instantly accessible web interface. Teams can explore, test, and share designs without friction.

Learn More →

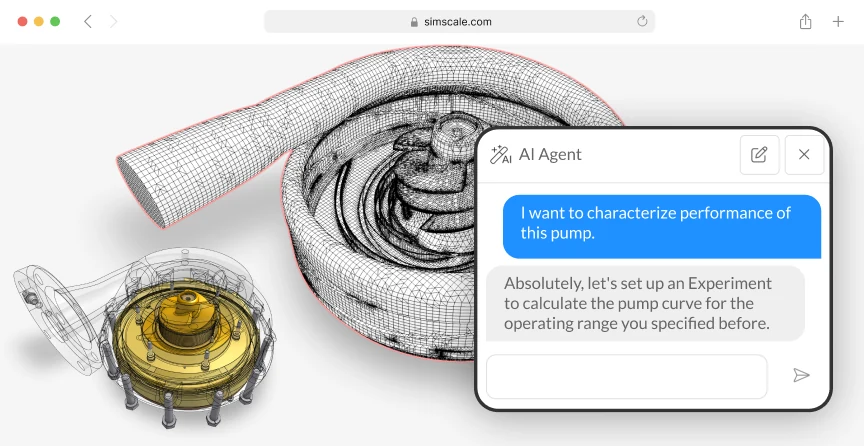

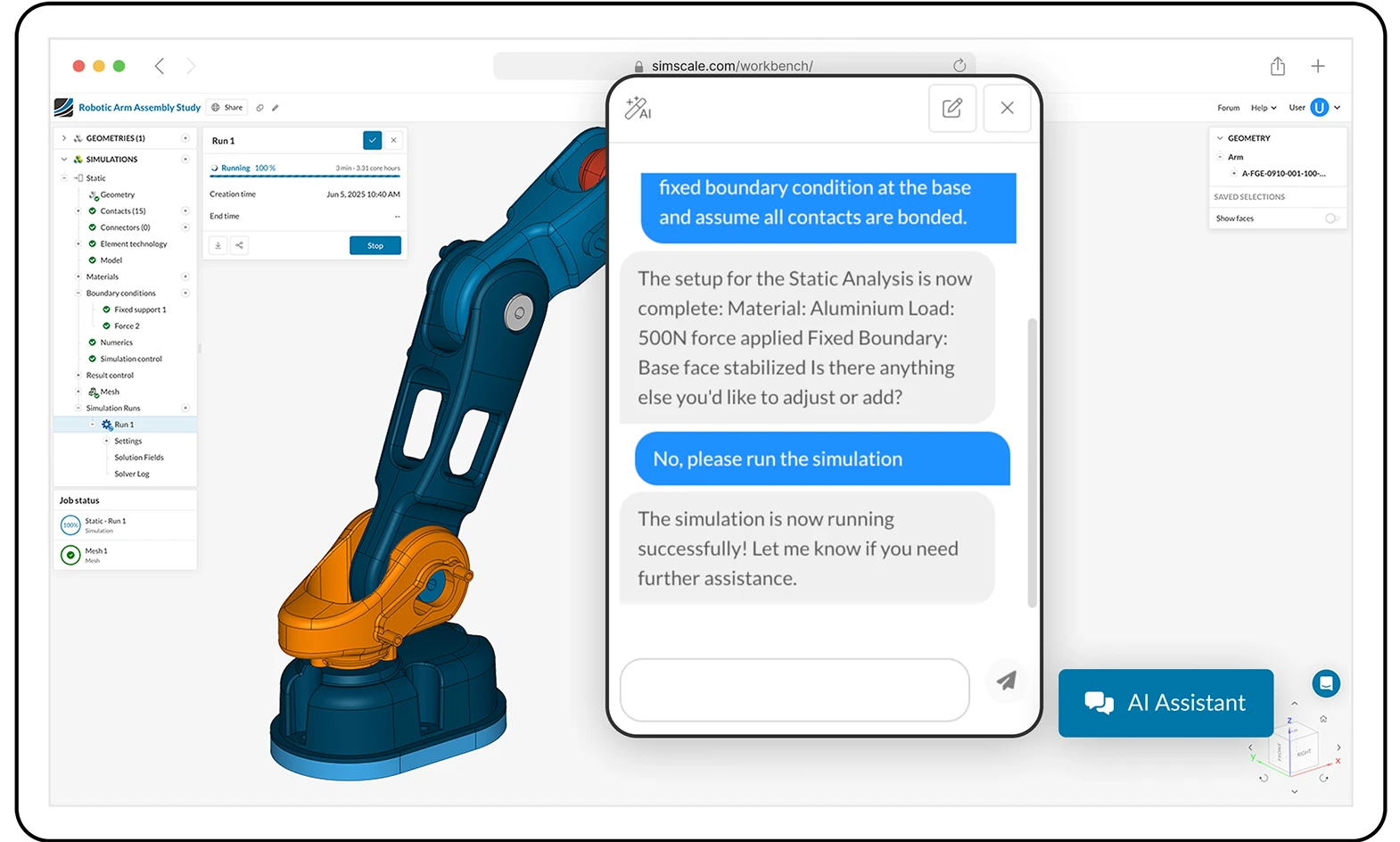

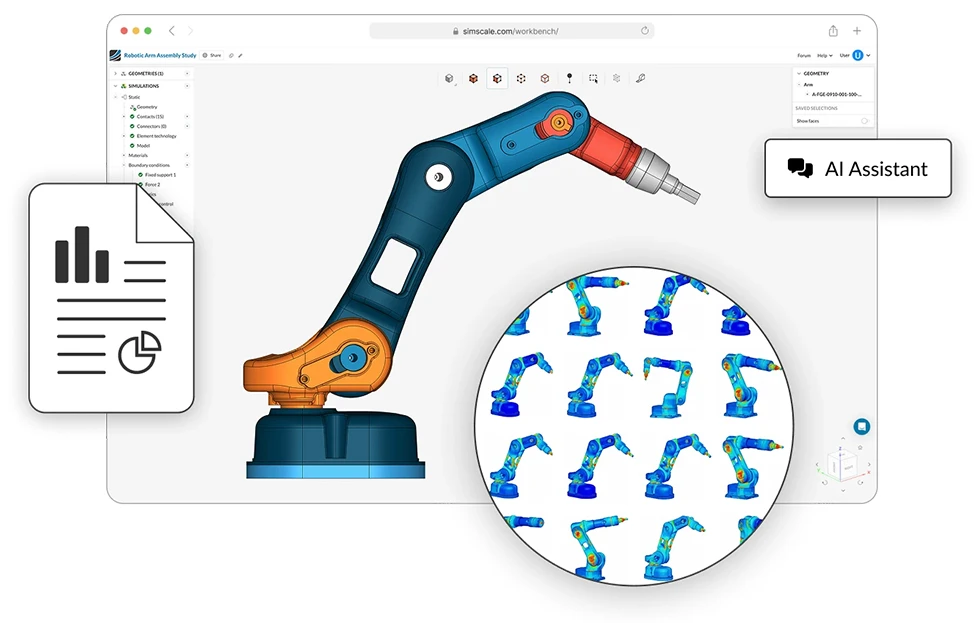

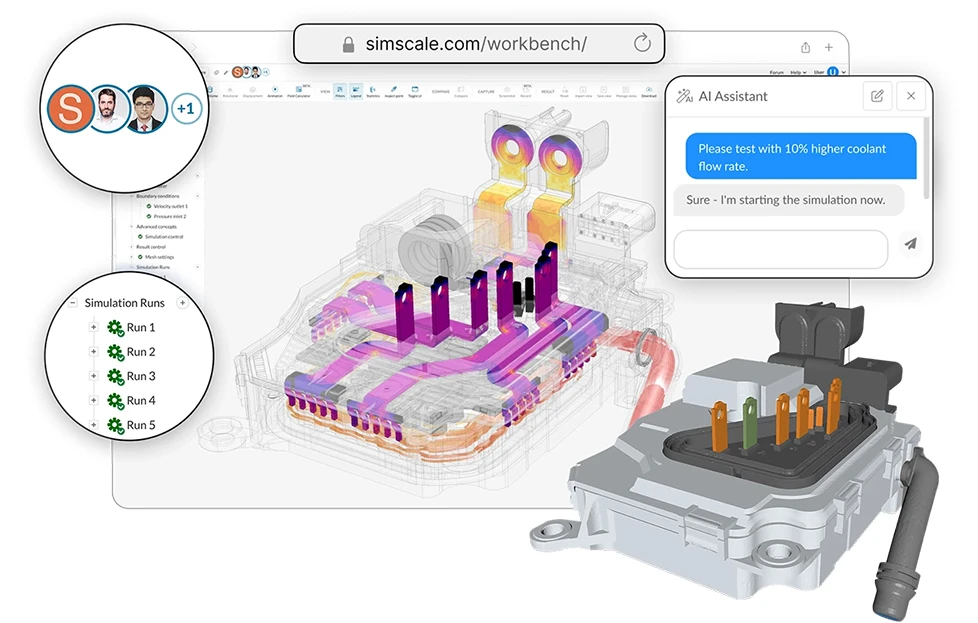

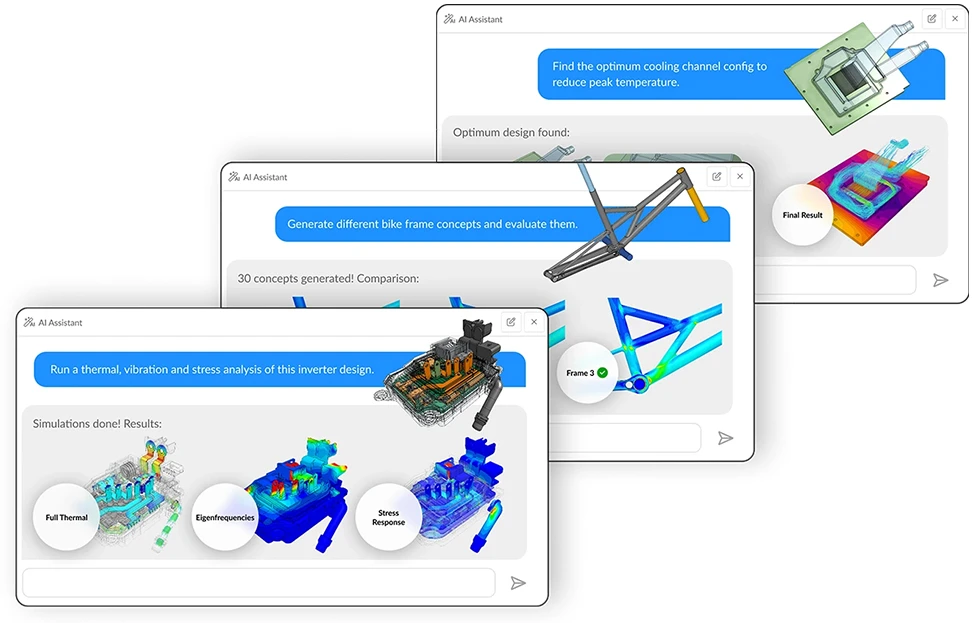

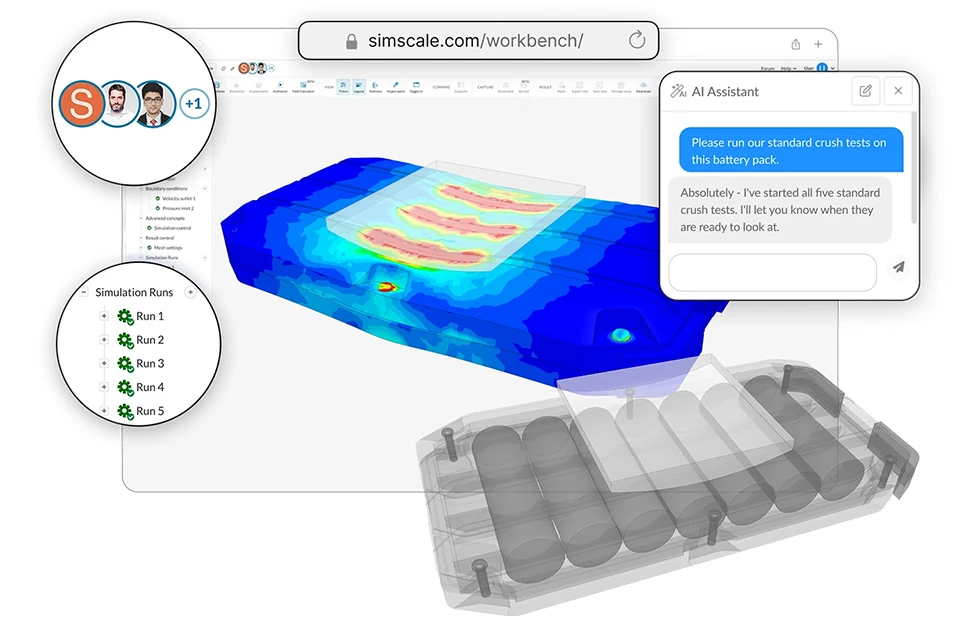

Agentic AI orchestrates simulation setup, execution, evaluation, and documentation. AI agents can run CAE workflows autonomously, understand intent, and reason through decisions, eliminating manual handoffs and speeding design iteration.

Learn More →

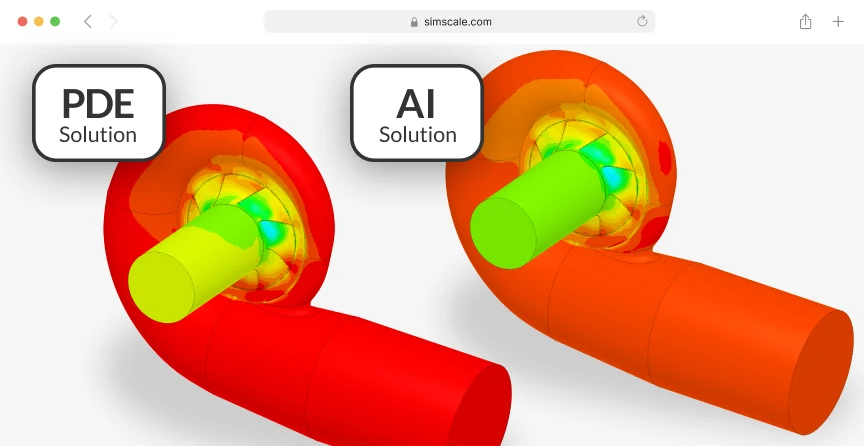

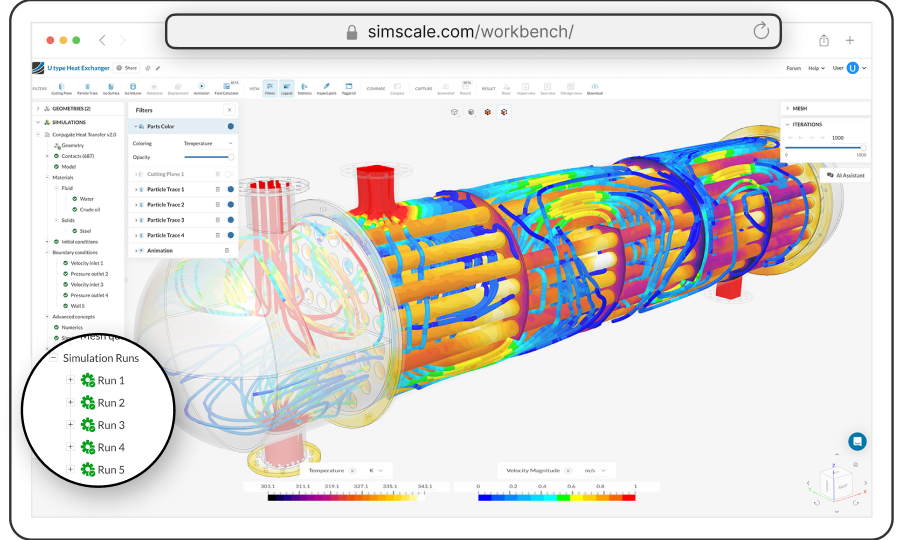

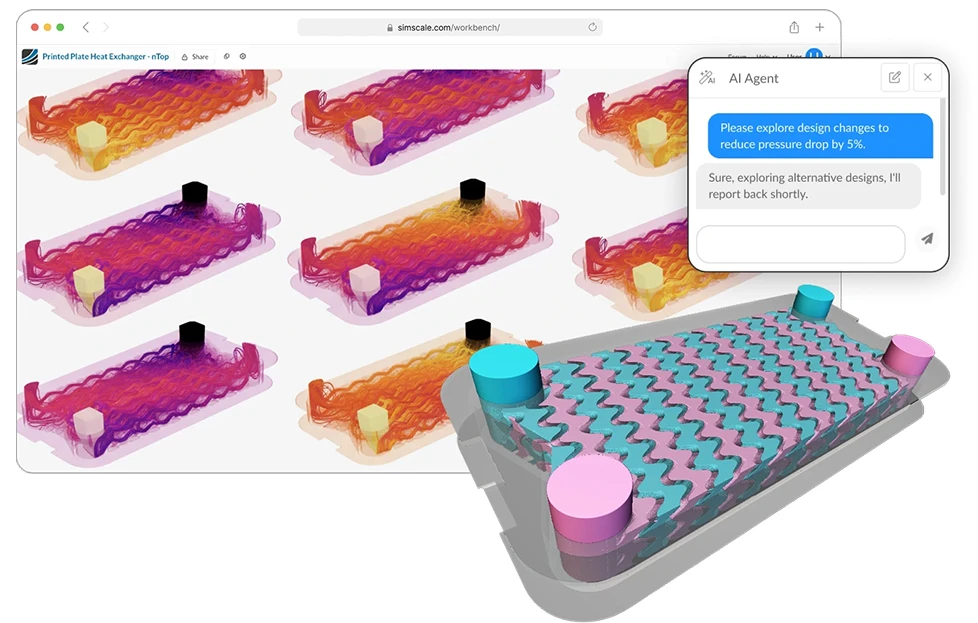

Instant prediction of physical behavior using AI models linked to high-fidelity simulation. Leverage past CAE data for instant parametric design optimization.

Learn More →SimScale combines Engineering AI, Physics AI, and multiphysics solvers in a single cloud-native environment — built for design exploration speed, scale, and control.

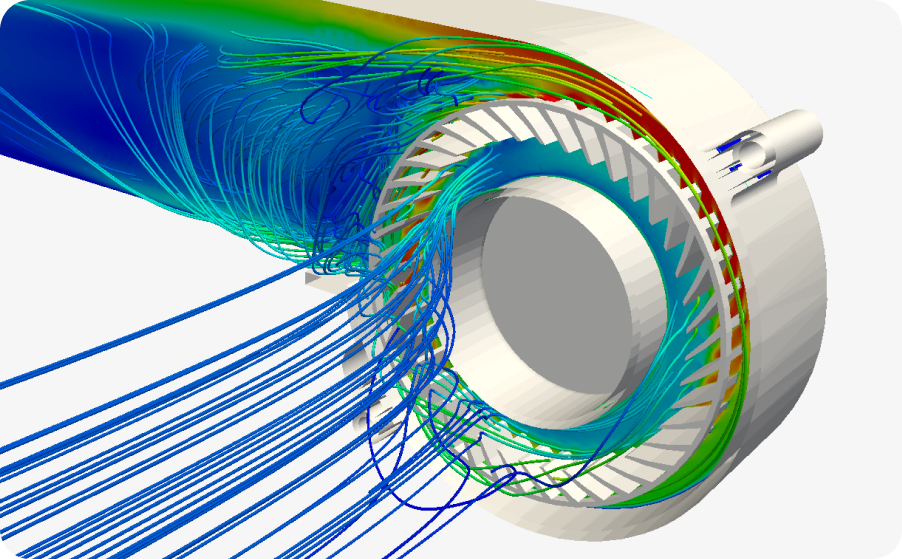

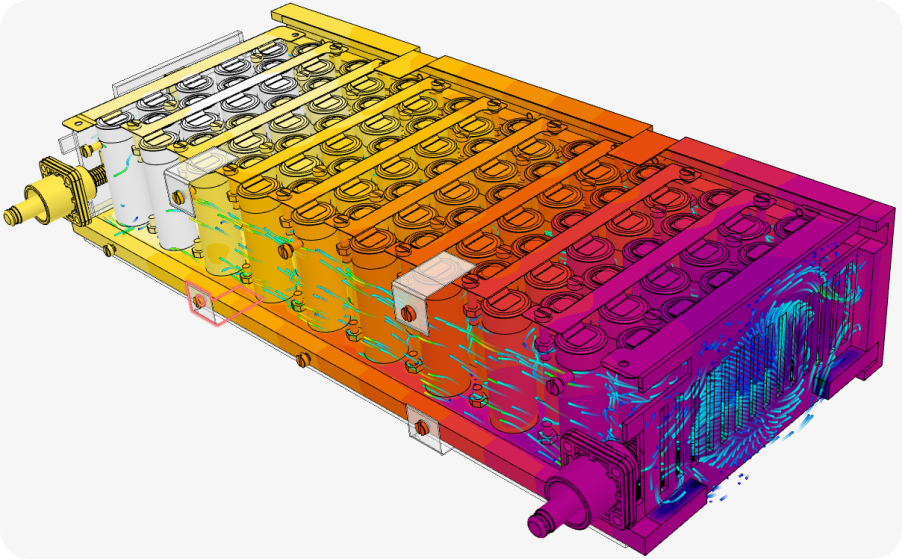

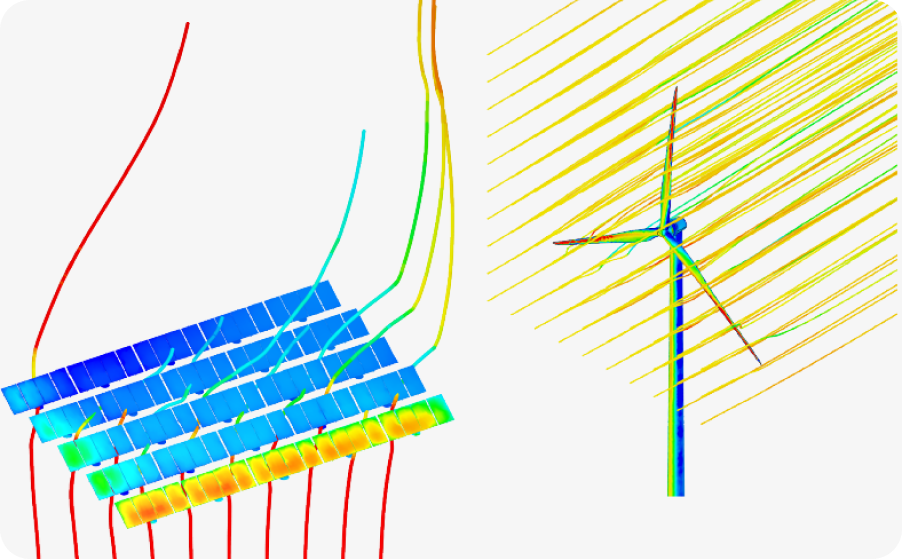

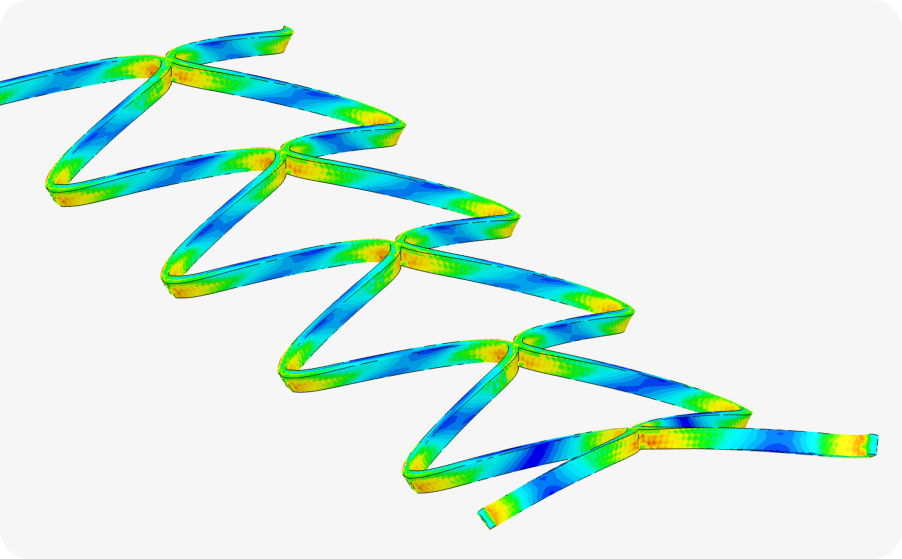

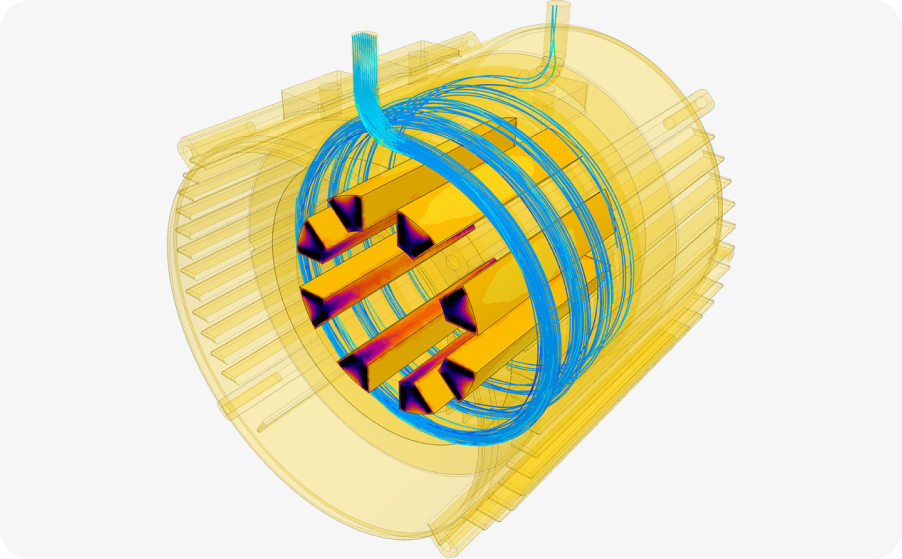

Integrated CFD, FEA, thermal, EM solvers – including physics solvers and AI / surrogate models – unified in one open platform.

Integrated Engineering AI agent drives workflows, ensures consistency and collaborated autonomously with the enterprise tool stack.

Fully automatic, elastic compute infrastructure, built-in data management so that every simulation can be used to maximum impact – backed up by enterprise grade security.

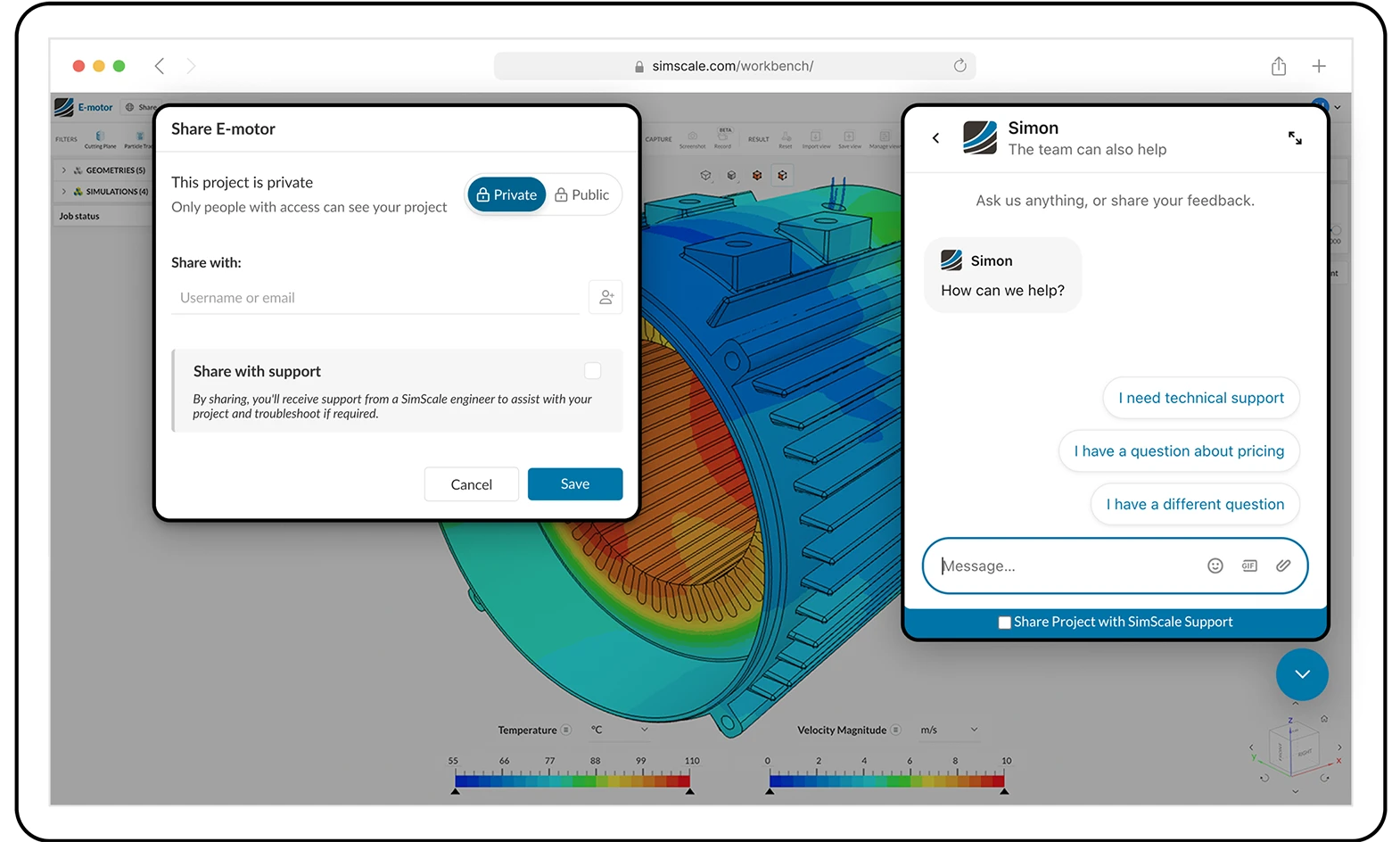

Browser-based environment with sharing and co-authoring for ultimate accessibility. Guided with AI and safely democratized with expert-owned templates.

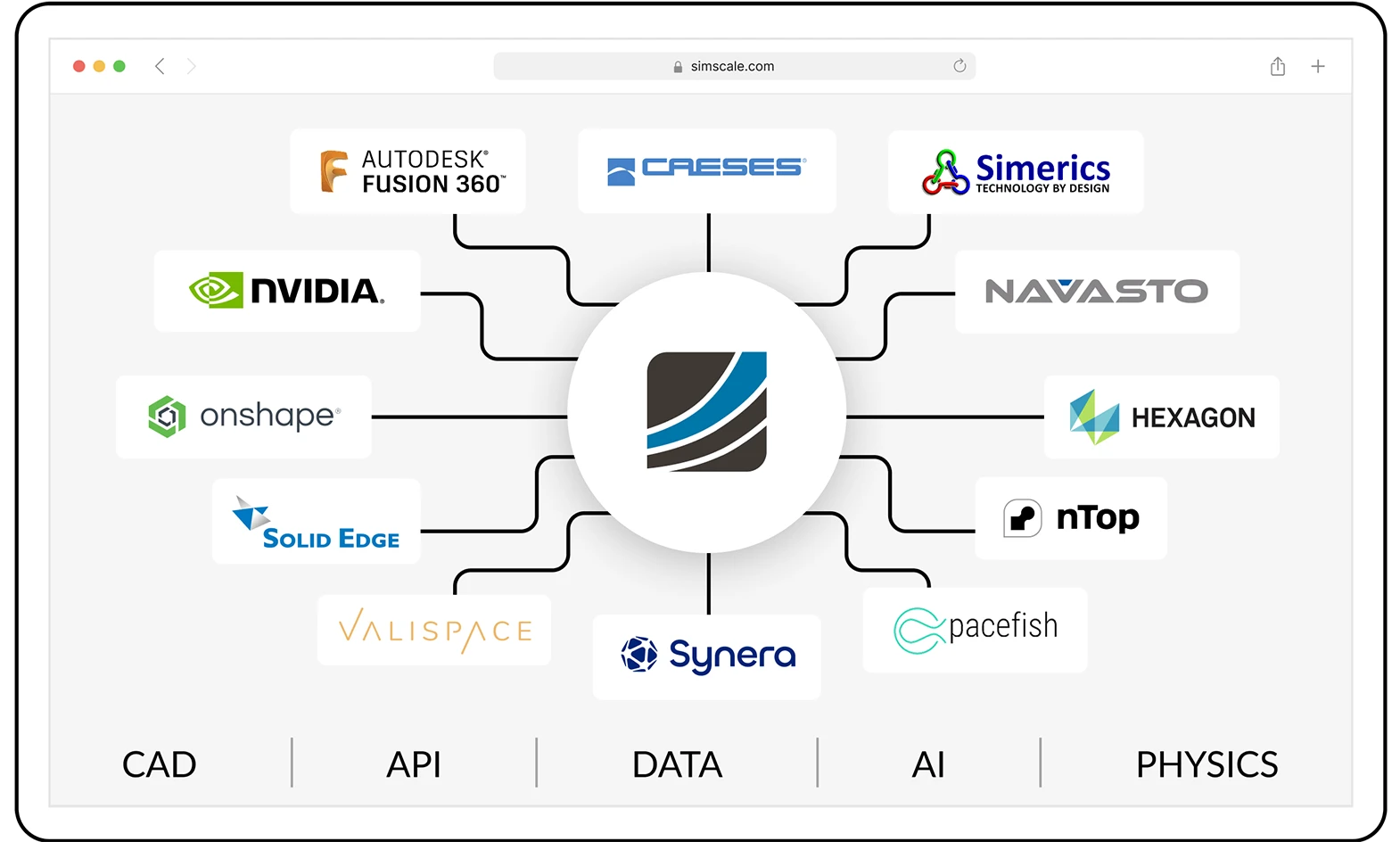

Broad interoperability through a strong partner ecosystem, while ready for integration with legacy CAE, third-party solvers, and external agents through APIs and data pipelines.

Explore more design options to submit better RFQs and protect margins.

“Months of engineering work can now be done in an evening.”

Shane McConn

Lead Mechanical Design Engineer at Silent-Aire

Compress your product development timeline with parallel simulation workflows.

“The key advantage of using SimScale for us is to extract fast design insights at the early stages. We can then arrive at a final design faster and have more confidence when moving to the physical prototyping stage.”

Massimo Savi

Mechanical Engineer at ITW Automotive

Put simulation in every engineer’s hands with a zero-install, browser-based platform.

“Integrating simulation early in the product development process allows us to better understand the physics and gain confidence in design choices. With SimScale every design engineer has access to simulation.”

Clément Zémerli

Senior Simulation Engineer in Corporate Technology at Bühler

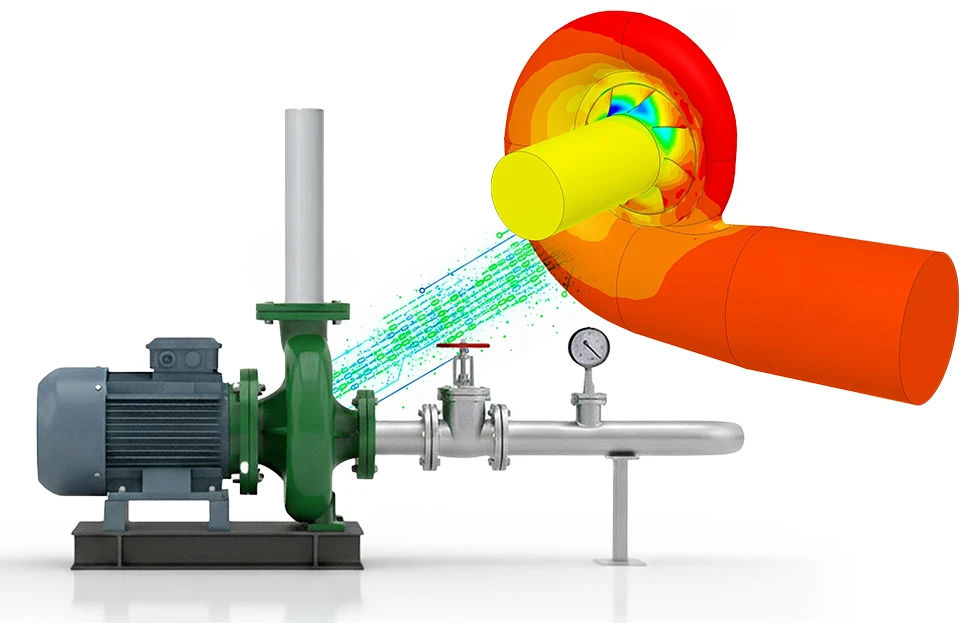

Replace expensive physical prototypes with high-fidelity virtual testing at scale.

“SimScale drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage) and simulation accuracy. It allows us to complete development cycles within days instead of months which gives us a massive advantage to our competition. I would say that this software is not evolutionary but rather disruptive.”

Benjamin van der Walt

Engineering Manager at Hazleton Pumps International (Pty) Ltd

Let AI agents autonomously set up, run, and document simulations end-to-end.

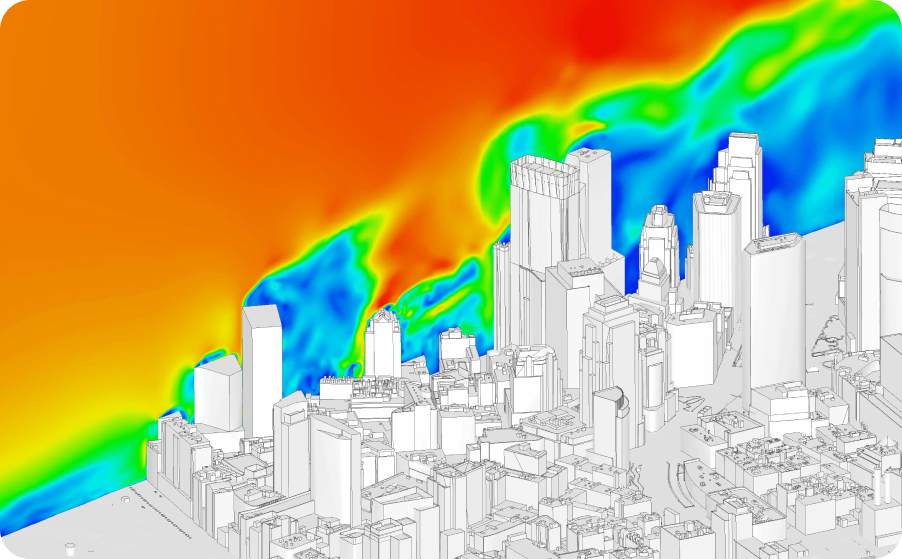

“…we were able to shorten our CFD simulation feedback loop, which in turn allowed us to iterate and evaluate many design options at the earliest design phases of our projects. This proved to be particularly innovative because design changes during this time have the potential for the biggest impact on performance.”

Anthony Viola AIA

Architect, Adrian Smith + Gordon Gill Architecture

Amplify your best engineers’ knowledge across the entire product team.

“SimScale was very easy to get started with. I was the only CFD expert and in several projects, people from the department decided to include CFD as they found it very easy to use after a 1-hour explanation… This has broadened access to simulation within Tecnalia.”

Lucas Juan Bernácer Soriano

Aeronautical Engineer at Tecnalia

Get faster and more reliable engineering insights to inform product decisions by connecting fast, Physics AI–powered models to real-world systems and data.

“I have been using SimScale in my product development routine (weekly) and it has been a game changer in critical design decisions where industrial equipment is used in large scale industrial operations.”

Vinícius Gonçalves

Senior Engineer at Vale

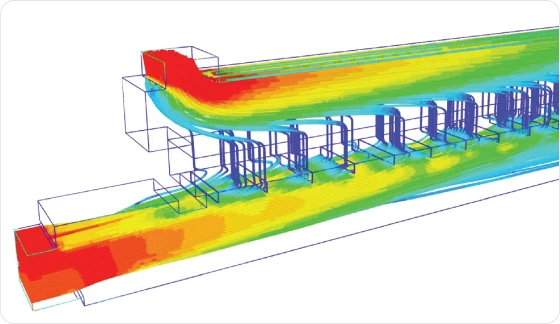

Bühler, a global leader in process engineering, rolled out SimScale’s cloud-native simulation platform to engineers across 25 departments. By giving 15% of its mechanical and process engineers browser-based access to CFD and FEA, Bühler scaled simulation company‑wide, accelerated development by weeks or months, and reduced reliance on costly physical tests.

Learn More

SimScale enables teams across industries to validate performance earlier, reduce risk, and scale simulation across fluid, thermal, structural and electromagnetic systems.

Free for testing & learning

For higher fidelity simulation work

For team collaboration

For broad simulation roll-outs

Explore Engineering AI with SimScale

Sign up for SimScale

and start simulating now