Documentation

This LED cooling validation case, for high power LED packaging with one heat sink, aims of to validate the following parameters:

The simulation results of SimScale were compared to the theoretical results presented in [Adam]\(^1\).

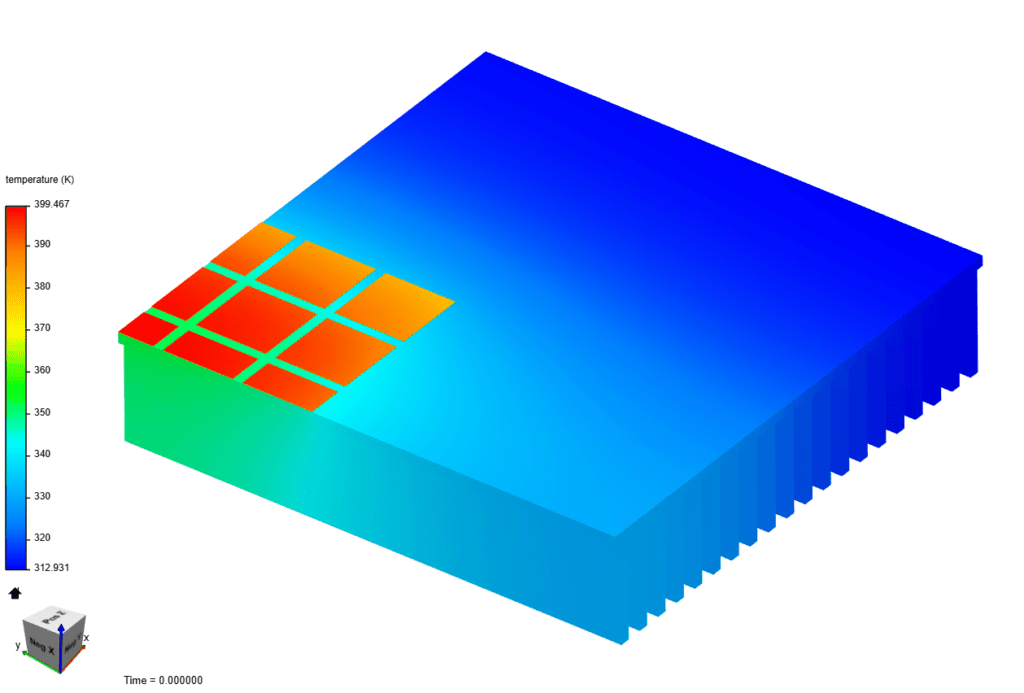

The typical geometry used for the case is as follows:

It represents a heat sink of dimensions 100 x 100 \(mm\) with 25 LEDs attached through Thermal Interface Material (TIM) patches of dimensions 7 x 7 x 0.1 \(mm\). Only one-quarter of the geometry is modeled to leverage the symmetry. Gaps of 10, 5, and 1 \(mm\) between LEDs were tested, with each model shown below for comparison:

Tool Type: Code Aster

Analysis Type: Heat transfer, linear, steady-state.

Mesh and Element Types:

| Case | Gap \([mm]\) | Mesh Type | Number of Nodes | Element Type |

|---|---|---|---|---|

| A | 10 | 1st order tetrahedral | 828917 | Standard |

| B | 5 | 1st order tetrahedral | 824569 | Standard |

| C | 1 | 1st order tetrahedral | 824369 | Standard |

The meshes were computed using the Tet-dominant algorithm with manual mesh sizing and local refinements for the TIM regions. The goal was to keep 2 elements across the thickness of the thin-walled parts, like the heat sink fins and TIM patches.

Material:

The thermal conductivity of the TIM was computed to achieve a total resistance of 9 \(K/W\), according to [INFINEON]\(^2\) with the relation:

$$ \kappa = \frac{t}{RA} $$

Where:

Boundary Conditions:

The following table relates the simulation runs for each case and the combinations of applied boundary conditions:

| Run | Load 1 \([W]\) | Load 3 \([W]\) | Load 5 \([W]\) | Convective flux 10 \([\frac{W}{m^2K}]\) | Convective flux 25 \([\frac{W}{m^2K}]\) | Convective flux 50 \([\frac{W}{m^2K}]\) | Convective flux 75 \([\frac{W}{m^2K}]\) | Convective flux 100 \([\frac{W}{m^2K}]\) |

|---|---|---|---|---|---|---|---|---|

| 1 | X | X | ||||||

| 2 | X | X | ||||||

| 3 | X | X | ||||||

| 4 | X | X | ||||||

| 5 | X | X | ||||||

| 6 | X | X | ||||||

| 7 | X | X | ||||||

| 8 | X | X | ||||||

| 9 | X | X | ||||||

| 10 | X | X | ||||||

| 11 | X | X | ||||||

| 12 | X | X | ||||||

| 13 | X | X | ||||||

| 14 | X | X |

The reference solution is of the analytical type, as presented in [ADAM]\(^1\). It is given in terms of the temperature at the center point as a function of the thermal load and convection coefficients.

Comparison of temperature at the mid point is shown for each case:

The deviation of the results with respect to [ADAM]\(^1\) in the cases of gap 5 mm and 1 mm can be attributed to a non-uniform temperature distribution at the base of the fins:

Tutorial: Thermal Analysis of a Differential Casing

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: March 22nd, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now