Documentation

In the field of solid mechanics, structural analysis is the analysis of the response of a structure and its behavior under certain loading conditions. A structure or an assembly may consist of several sub-components. The goal of structural engineers is to analyze all the sub-components but also the structure as a whole. This can be achieved by typically trying to answer the following question:

“Is it going to withstand the loading, or is it going to fail?”

Stress and strain are two really important quantities when it comes to structural analysis.

In a solid, stress (σ) is defined as the internal force (F) within the material that opposes any external loading and runs through any given cross-section (A):

$$\sigma = \frac{F}{A}$$

Any solid under stress will experience deformation. Strain (ε) is a dimensionless quantity that quantifies the relative deformation of materials under stress. Strain is expressed as:

$$\epsilon = \frac{dL}{L}$$

where L is the undeformed length of the solid element and dL is its relative deformation.

Deriving the stresses and strains of a given component is the major goal of structural analysis. However, there are other equally important quantities and analysis types. Typical examples are natural frequencies and mode shapes, vibration responses, buckling, fracture/crack propagation, and material fatigue.

The relationship between stress and strain is:

$$\epsilon = \frac{\sigma}{E}$$

where E is a characteristic material constant known as modulus of elasticity, elastic modulus, or simply Young’s modulus. This property was named after the British scientist Thomas Young.

It is a mechanical property of linear elastic solid materials which quantifies how rigid/stiff a material is. Young’s modulus is often expressed in pressure/stress units (Pa or psi).

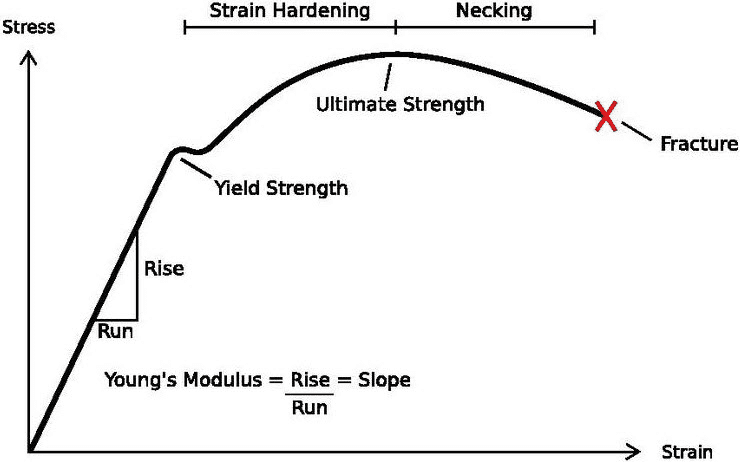

Talking about materials, it’s worth mentioning the stress-strain curve. In engineering structural analysis, the most commonly encountered materials are ductile. A part made of a ductile material is able to withstand excessive strains before failure. Figure 1 demonstrates a typical stress-strain curve of ductile materials.

The stress-strain curve is unique for any material and is typically determined through physical testing. There are several types of tests, for example, tensile, compression, and bending tests which lead to material characterization. The stress-strain curve provides engineers and designers with important information about material limits and the risk of failure.

Willing to learn more about stresses and strains and the various stress-strain relationships based on different material types? Then make sure to read our article on the Stress-Strain curve.

During the design process of a component or a structure, the structural analyst has to ensure that the designed model will withstand all sorts of loads that it is going to experience throughout its designated lifetime. This very much depends on the material properties and the stress-strain characteristic curve that comes with it. There are two main concerns when it comes to material strength:

The designer must ensure that the developed stresses will never surpass the Ultimate and/or Yield Strength of their product. Of course, the maximum allowable stress should be somewhat lower than these two limits. The reason for that is to account for uncertainties or unpredicted extreme loading conditions. Thus, maximum allowable stress and, in turn, a factor of safety (FoS) of the design can be defined.

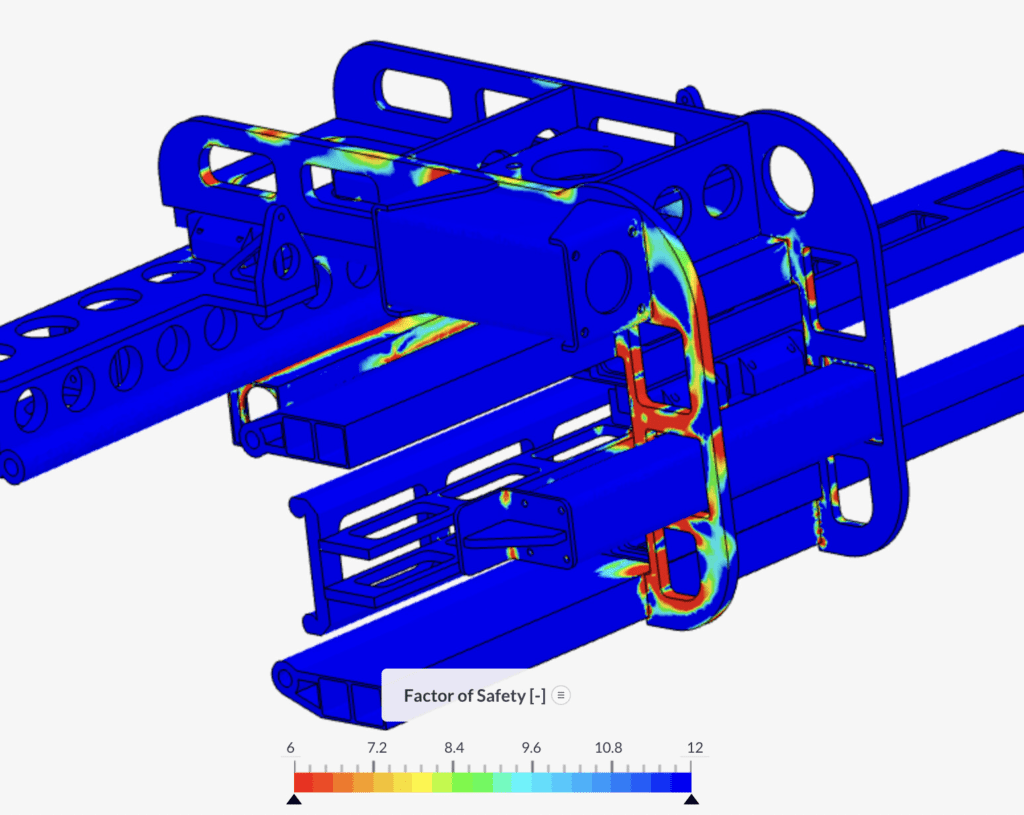

Structural analysis helps to ensure that safety-critical equipment has high safety factors to account for unexpected loading regimes.

$$FoS=\frac{\text{max. allowable stress}}{\text{max. working stress}}$$

In the case of a simple, statically determinate problem, the reaction and internal forces, which are important for structural analysis, are calculated employing simple statics. This case is really straightforward since the number of unknowns typically equals the number of equations to maintain equilibrium. This is the simplest example of structural analysis.

However, there are cases where the number of unknowns exceeds the number of equilibrium equations. That could be the case of a propped cantilever beam, for instance. This is now a statically indeterminate problem, and we should use alternative methods to solve it.

There are three main methods of structural analysis:

Work and energy methods oftentimes can be solved by hand and are generally good for smaller and simpler components. Matrix methods are quite useful in modern structural engineering where there is a need for analyzing larger assemblies (i.e. aircraft). A subcategory, or in other words, the evolution of the matrix methods, is the finite element method (FEM).

The FEM is particularly good for continuum structures representing real-life models. Make sure to read our article about Finite Element Analysis. This will help you understand how FEM works in practical engineering problems.

Of course, talking about structural analysis solution methods could be endless. It is hard to cover all these details in a single article. One academic textbook I possess and I like to retrieve when looking for more information about structural problems is Aircraft Structures for Engineering Students by T.H.G. Megson. [2]

With the development of modern computing, engineers and designers implement structural analysis methods more regularly in their daily jobs. They can use dedicated FEA or structural analysis software to reduce the number of physical prototypes required for testing at the component or assembly level. A computer now handles all the sets of mathematical equations and unknowns. This allows engineers to perform speedy computations and reach design decisions faster.

New technology has flattened the barriers. Now structural analysis simulation is truly accessible through any web browser leveraging the power of cloud computing. Engineers can run multiple designs in parallel and post-process simulation results online. SimScale provides structural analysis software right in your web browser. SimScale makes engineering simulation easily accessible in every industry and truly scalable using premium cloud computing infrastructure.

As discussed, there are several structural analysis types. Based on the application type, structural analysis can be employed to solve different problems. It can either be a simple linear static analysis or a more complex non-linear one.

Let’s take a look at different examples of structural analysis by going through the following analysis types.

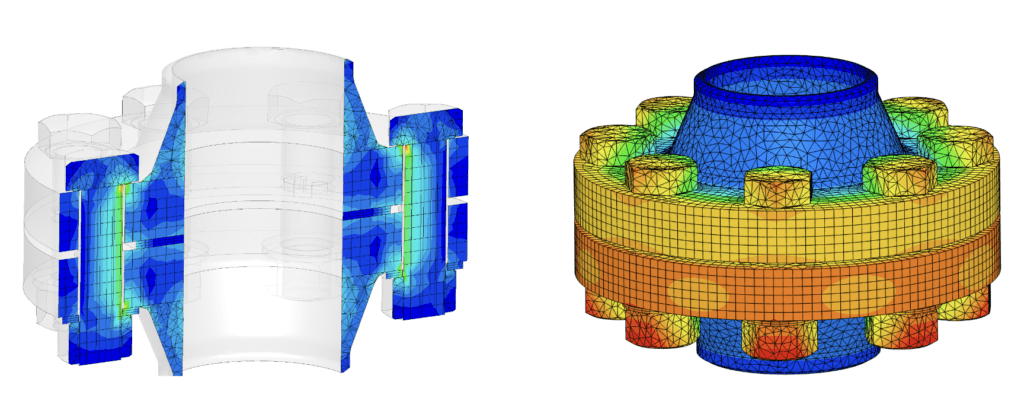

The static analysis type allows time-independent calculation of displacements, stresses, and strains in one or multiple solid components. The results are a consequence of the applied constraints and loads, for example, bearings, gravity, forces, etc.

The results enable engineers to evaluate if the component of interest deforms in an undesired manner. Will help understand if a critical stress state occurs that will pose threat and risk failure. Feel free to check the following bolted flange example to get an idea of static structural analysis example.

The dynamic analysis type allows time-dependent calculation of displacements and stresses/strains in one or multiple solid components. Comparing it to a simple static analysis, it now differs due to the fact that inertia effects are also taken into consideration through variation in time.

The results allow engineers to analyze single timesteps as well as the dynamic performance as a function of time. Similar to static analysis, the model adequacy with respect to maximum allowable stresses and deformations can be assessed over time. Drop-test and impact assessments are characteristic examples of dynamic structural analysis.

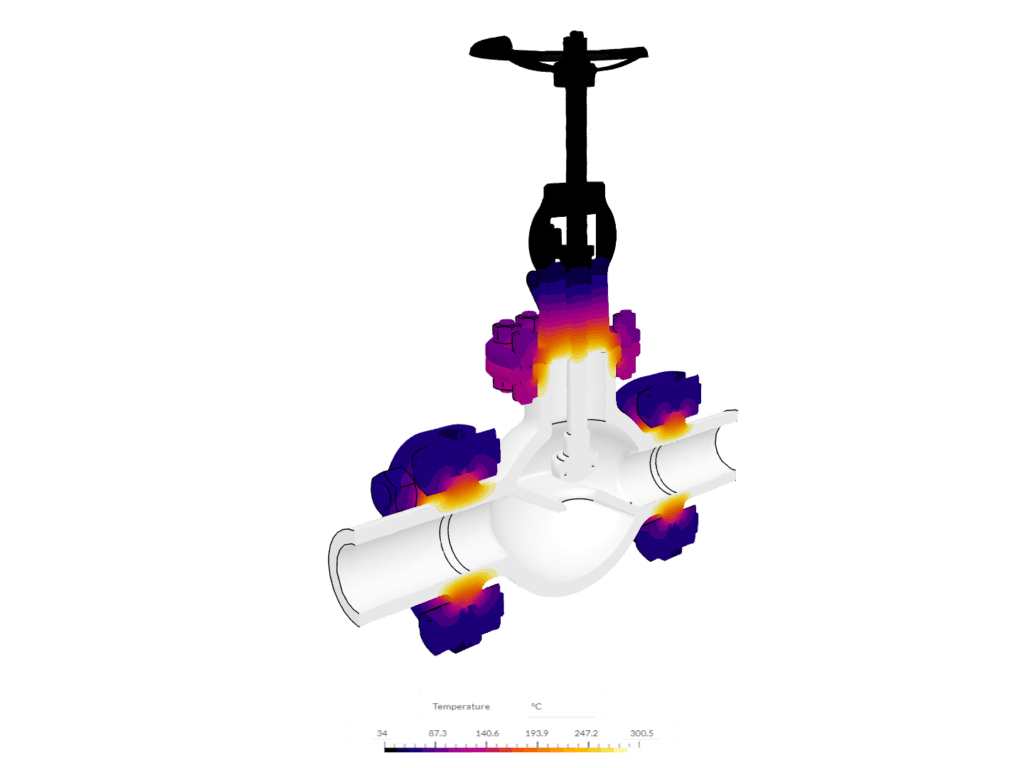

The thermomechanical analysis is beneficial when trying to compute the combined thermal and structural behavior of a component or assembly. It is actually helpful in calculating the stresses of a solid body caused by combined thermal and structural loads. The calculation of the thermal and structural results is sequential. The process typically starts with a thermal step which then serves as input to a consecutive structural step. It is essentially a combination of a thermal and structural analysis.

Studying the thermal shock of components, like a spark plug or a globe valve, comprise typical thermomechanical application examples.

The frequency Analysis simulation type allows the computation of natural (under no external load excitation) frequencies (eigenfrequencies) of oscillation of a structure. It also permits the calculation of the corresponding oscillation mode shapes (eigenmodes). The resulting frequencies and deformation modes depend on the geometry and material distribution.

Frequency analysis results help evaluate the overall rigidity of the structure and understand what are the “dangerous” frequencies which might lead to resonance. Such results are a valuable input to seismic studies, wind loading studies or vibration studies. A quite common example is vibration studies of electronic equipment like in this Electric Vehicle (EV) battery module.

The frequency analysis is often the first step to a later Harmonic Analysis. The harmonic analysis enables the engineers to simulate the steady-state structural response of solids excited by periodical (sinusoidal) loads. It is quite similar to a dynamic analysis where inertia effects are taken into account, but it is different in the sense that now the results are no longer time-dependent but frequency-dependent. In other words, the harmonic analysis makes it possible to compute the response of a structure under vibrating forces or displacements over a defined frequency spectrum. Such studies can also take damping effects into account.

The EV battery module case mentioned above is a nice example of a combined frequency and harmonic analysis simulation for electronic equipment.

| Eigenmode | Eigenfrequency |

| 1.0 | 233.433 |

| 2.0 | 236.206 |

| 3.0 | 251.691 |

| 4.0 | 362.203 |

| 5.0 | 364.132 |

You can start exploring all the different structural analysis types with SimScale. You can leverage cloud computing tools and simulate hundreds of designs in parallel on the cloud without the need for any sophisticated hardware — right from your web browser.

If you liked this article and you are new to FEA, do not miss our FEA Guide, which will give you enough material to get you started. Try our structural and thermomechanical tutorials now and explore the different plans that can bring you onboard.

References

Last updated: June 6th, 2024

We appreciate and value your feedback.

What's Next

What is von Mises Stress?Sign up for SimScale

and start simulating now