Documentation

This validation case belongs to solid mechanics. In this case, an infinite cylinder is subjected to a voluminal load. The parameter being validated is:

SimScale simulation results were compared to the analytical solution presented in [SSLA100]\(^1\).

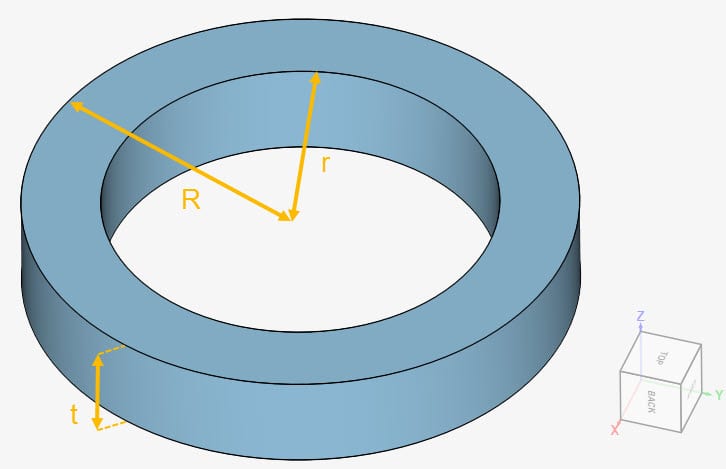

The geometry for this project consists of a slice of an annulus between two cylinders, as seen in Figure 1:

The dimensions of the geometry are given in Table 1:

| Geometry parameters | Dimension \([m]\) |

| Outer radius \((R)\) | 1.4 |

| Inner radius \((r)\) | 1 |

| Thickness of the slice \((t)\) | 0.5 |

Tool Type: Code_Aster

Analysis Type: Linear static

Mesh and Element Types: The mesh used in this case is a second-order mesh created in SimScale with the standard algorithm.

Table 2 contains details to the resulting mesh:

| Mesh Type | Nodes | Element Type |

| Second-order standard | 991445 | Standard |

Figure 2 shows the standard mesh used for this case:

Material:

Boundary Conditions:

The boundary conditions will be defined based on the following nomenclature:

Note

Since the volume load is in cylindrical coordinates\(^1\), it was necessary to convert it to Cartesian coordinates using trigonometric functions. The resulting input formulae are:

$$Load_x = (x^2+y^2)cos(atan2(y,x)) \tag {1}$$

$$Load_y = (x^2+y^2)sin(atan2(y,x)) \tag {2}$$

$$Load_z = 0 \tag {3}$$

In equations 1 and 2, the \((x^2+y^2)\) term represents radius squared. The second part of the equations, consisting of trigonometric functions, is responsible for the conversion from cylindrical to Cartesian coordinates. As a result, the loads will be applied in a radial direction.

The analytical solution for the displacements of the inner and outer wall are presented in [SSLA100]\(^1\). Find below a comparison between SimScale results and the analytical solution:

| Radius \([m]\) | Analytical displacement\(^1\) \([m]\) | Displacement – SimScale \([m]\) | Error [%] |

| 1 | 0.521309 | 0.521259 | -0.0096 |

| 1.4 | 0.442031 | 0.441986 | -0.0102 |

In Figure 5, we can see the resulting displacement contours. SimScale results show great agreement with the analytical solution.

Last updated: September 4th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now