Documentation

The purpose of this numerical simulation is to validate the following parameters of incompressible Large Eddy Simulation (LES) of flow over a cylinder:

The numerical simulation results of SimScale were compared with the experimental results. The flow regime selected for the study is classified as sub-critical with a flow reynold number of Re=3900.

Import validation project into workspace

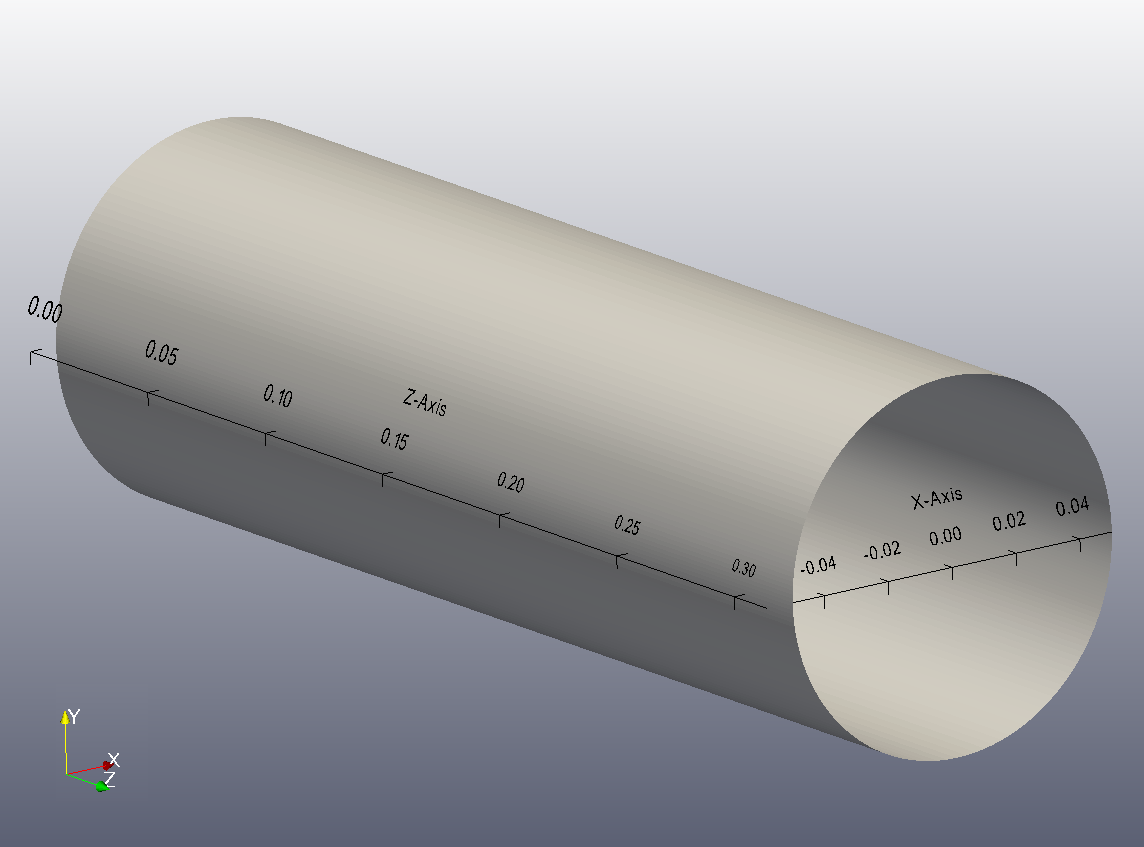

The geometry of the study is a straight cylindrical body (see Fig.1.). A brief description of the dimensions is provided by the table below.

| Length | Diameter | |

|---|---|---|

| Value [m] | πD | 0.1 |

An O-type domain was selected as the flow domain around the cylinder. The domain was 15D in the radial direction and πD in the span-wise direction (see Fig.2.). For this study a structured hexahedral mesh was created with the open source ‘BlockMesh-tool’. The grid nodes are distributed by a geometric grading in the radial direction. Further, the nodes are clustered near the stagnation point and in the wake region along the stream-wise direction. The mesh is based on a y-plus (y+) criterion of y+<1 in the radial direction. The complete details of the mesh are listed in the following table:

Mesh and Element types :

| Mesh type | Cells in radial | Cells in circumferential | Cells in spanwise | Number of nodes | Type |

|---|---|---|---|---|---|

| blockMesh | 165 | 204 | 34 | 1144440 | 3D hexahedral |

The numerical analysis performed is detailed as follows:

Tool Type : OPENFOAM®

Analysis Type : Incompressible Large Eddy Simulation

Sub-Grid-Scale Model : Smagorinsky with Cube-Root-Volume delta

Fluid:

Boundary Conditions:

The inlet boundary was set as a non-turbulent fixed velocity condition, while a pressure boundary condition was applied at the outlet. For the spanwise boundaries a symmetry condition was applied. The following table provides the further details.

| Boundary type | Velocity | Pressure |

|---|---|---|

| Inlet | Fixed Value: 0.59 ms−1

|

Zero Gradient |

| Outlet | inletOutlet | Fixed Value: 0 Pa

|

| Wall no-slip | Fixed Value: 0.0 ms−1

|

Zero Gradient |

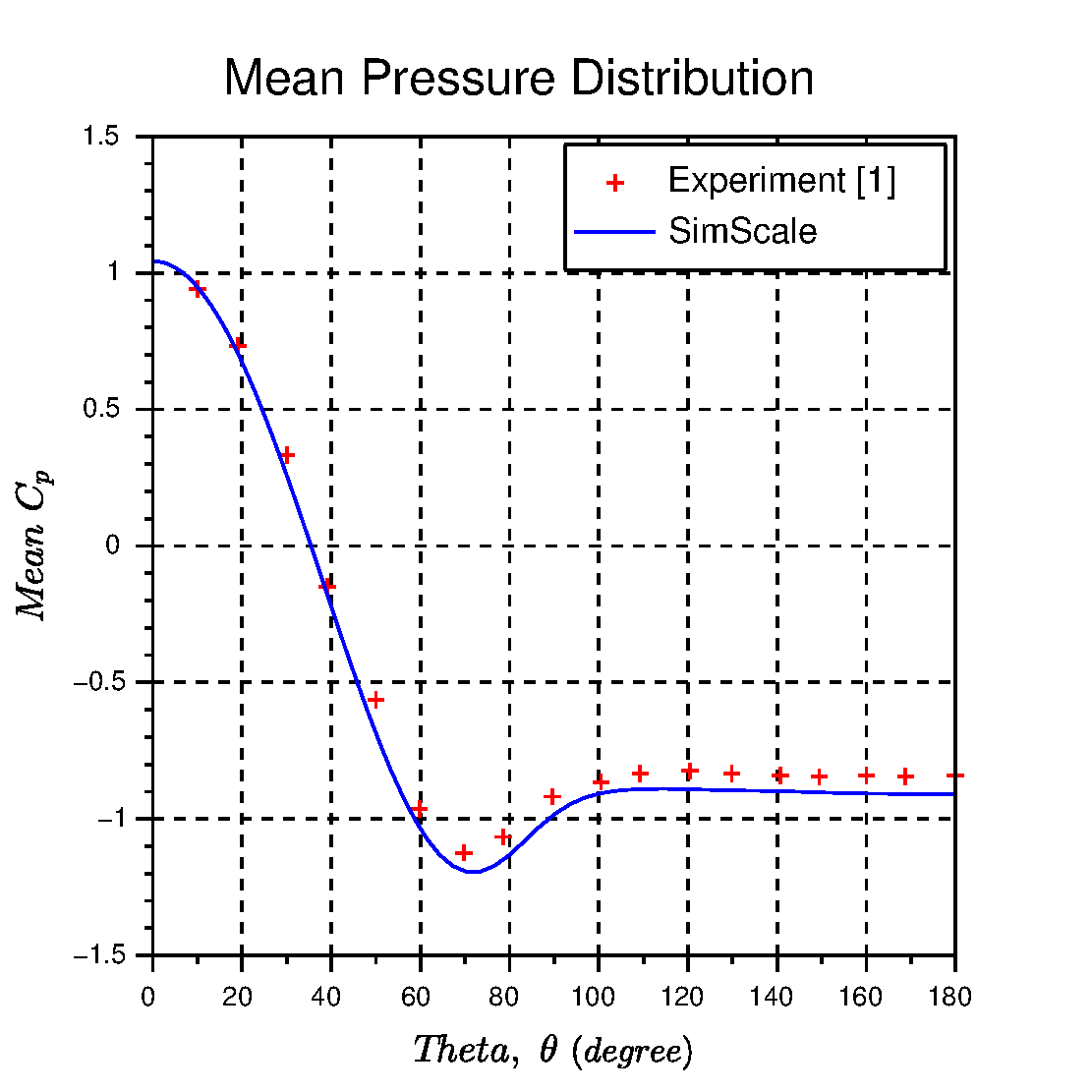

| Symmetry |

The numerical simulation results of mean pressure distribution and mean stream-wise velocity are compared with experimental data provided by C.Norberg [1] , L.Ong and J.Wallace [2] and L.M.Lourenco and C.Shih [3] . To ensure meaningful results, averaging was carried out over periods of atleast 100D/U∞ time units or about 21 vortex shedding cycles.

A comparison of the mean pressure distribution obtained with SimScale and experimental results is given in Fig.3A. The mean stream-wise velocity profile is compared with experimental data as shows by the Fig.3B.

Fig.3. Pressure distribution comparison (left), streamwise velocity profile comparison (right)

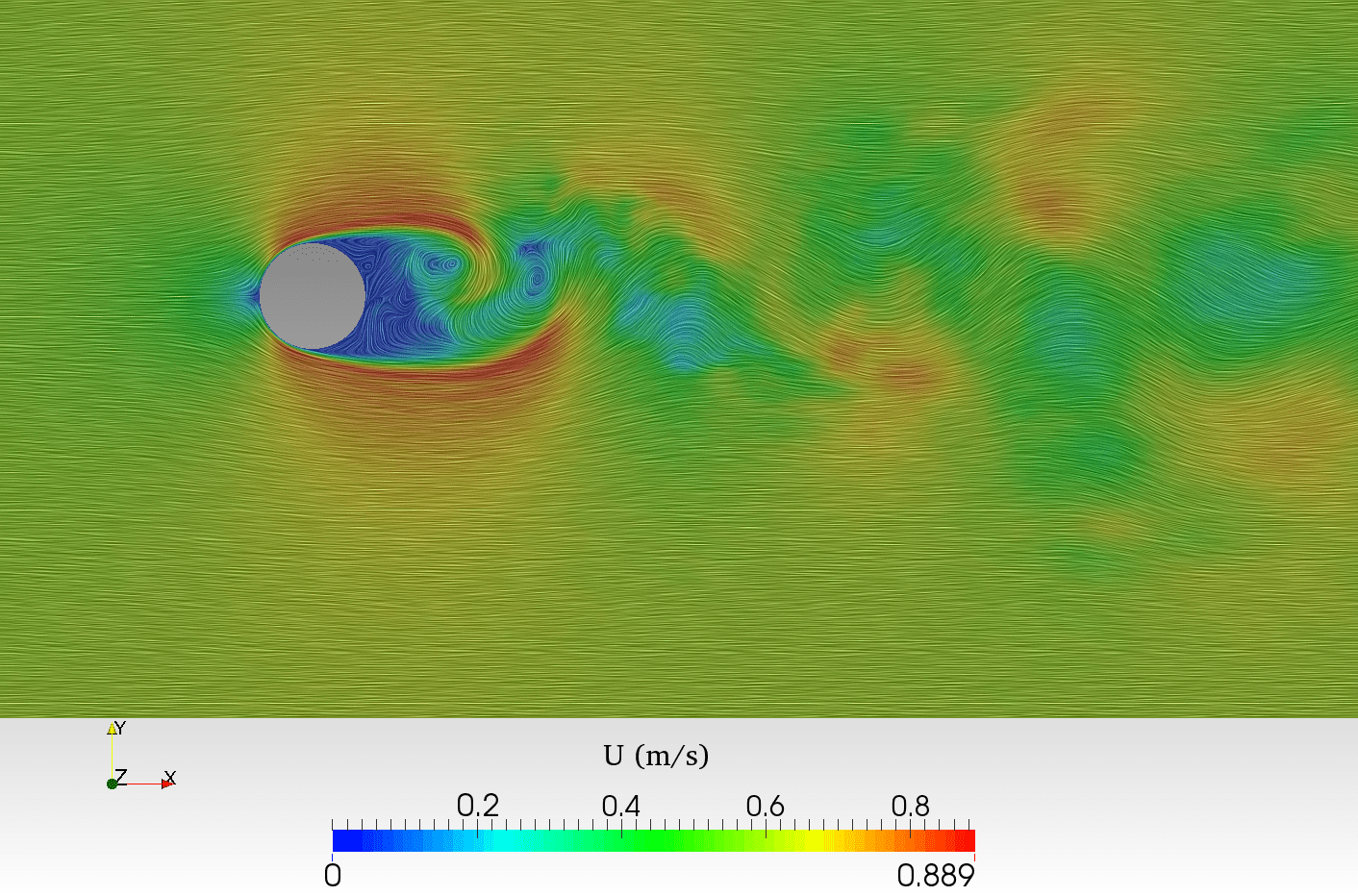

Fig.3. Pressure distribution comparison (left), streamwise velocity profile comparison (right)The instantaneous vorticity component wz, and averaged streamlines in the cross-section (x-y plane) are shown by the Fig.4A and Fig.4B respectively.

A visualization of the instantaneous flow field is shown along the cross-sectional and spanwise planes provided by Fig.5A and Fig.5B.

References

Last updated: August 30th, 2022

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now