Documentation

This validation case belongs to structural analysis, with the case of a pipe flange under the effect of bolt preload. The aim of this test case is to validate the following parameters:

The simulation results from SimScale were compared to test case results presented in [SSNV228]\(^1\).

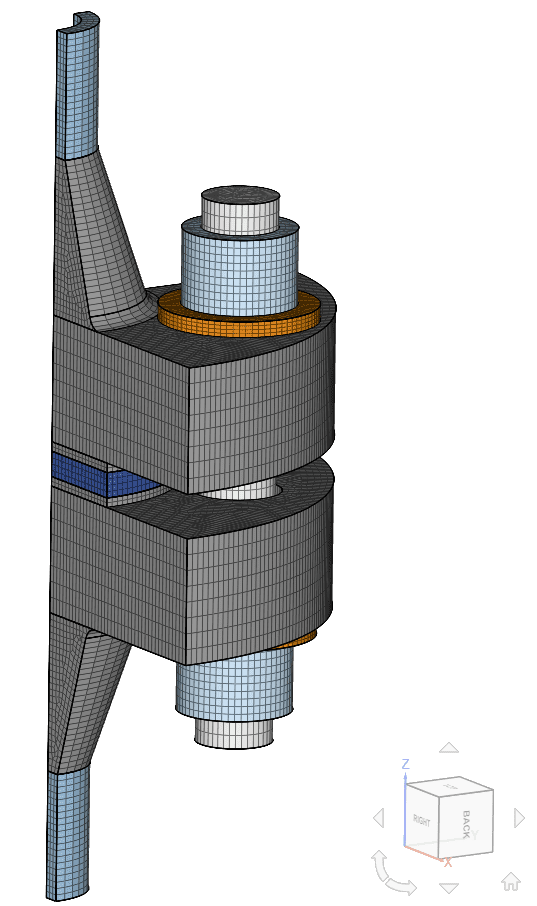

The geometry used for the case is shown below:

It represents a quarter section of a pipe bolted flange pair. The bolt shaft is simplified as a cylinder, as well as the nut. The model includes the pipe sections, flanges, a bolt, nuts, washers, and a gasket.

Tool Type: Code Aster

Analysis Type: Non-linear Static

Mesh and Element Types:

| Mesh Type | Number of Cells | Number of Nodes | Element Type |

|---|---|---|---|

| Standard (structured) | 50210 | 62344 | 1st Order Hexahedrals and Pyramids |

The mesh was computed using SimScale’s Standard Mesher algorithm. To optimize the performance of the FEA model, Sweep meshing refinement was used on the different parts, resulting in a structured mesh. Such a mesh consists of mapped hexahedral and pyramid elements, as can be seen in the figure:

Material:

Boundary Conditions:

The reference solution is of the numerical type, as presented in [SSNV228]\(^1\). It is given in terms of the mean stress on the bolt shaft:

$$ \sigma_{bolt} = 30\ MPa $$

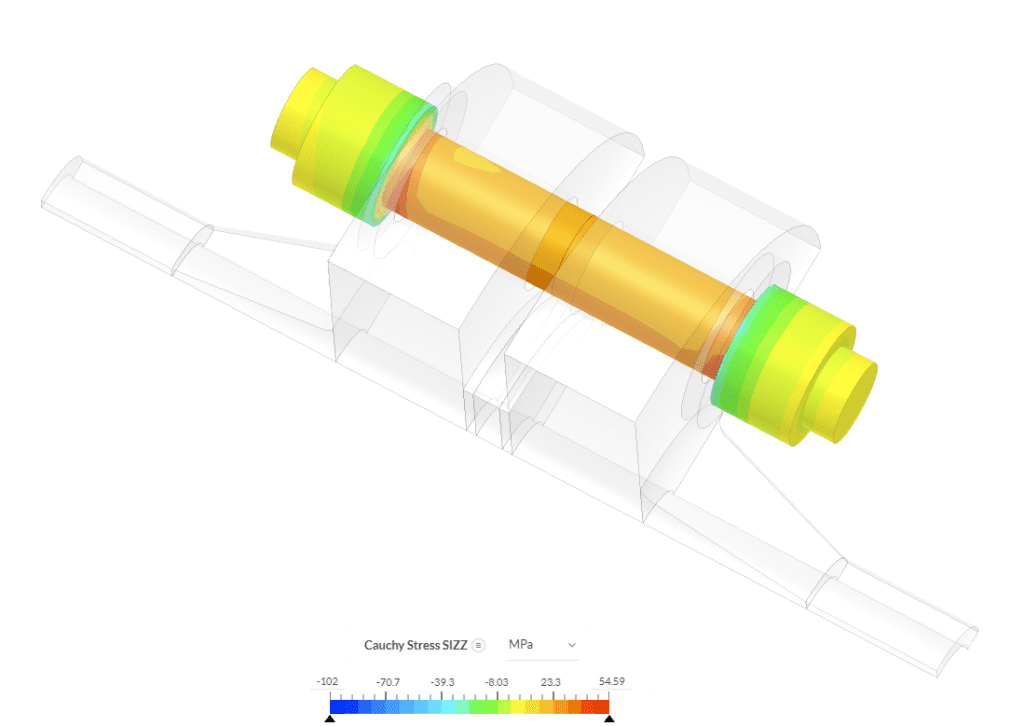

Comparison of the axial bolt stress \(\sigma_{ZZ}\) at a point data result control item located on the bolt shaft with the theoretical solution is presented below:

| FIELD | COMPUTED | REF | ERROR |

|---|---|---|---|

| \(\sigma_{ZZ}\) \((SIZZ)\) \([MPa]\) | 30.3135 | 30.0 | 1.05 % |

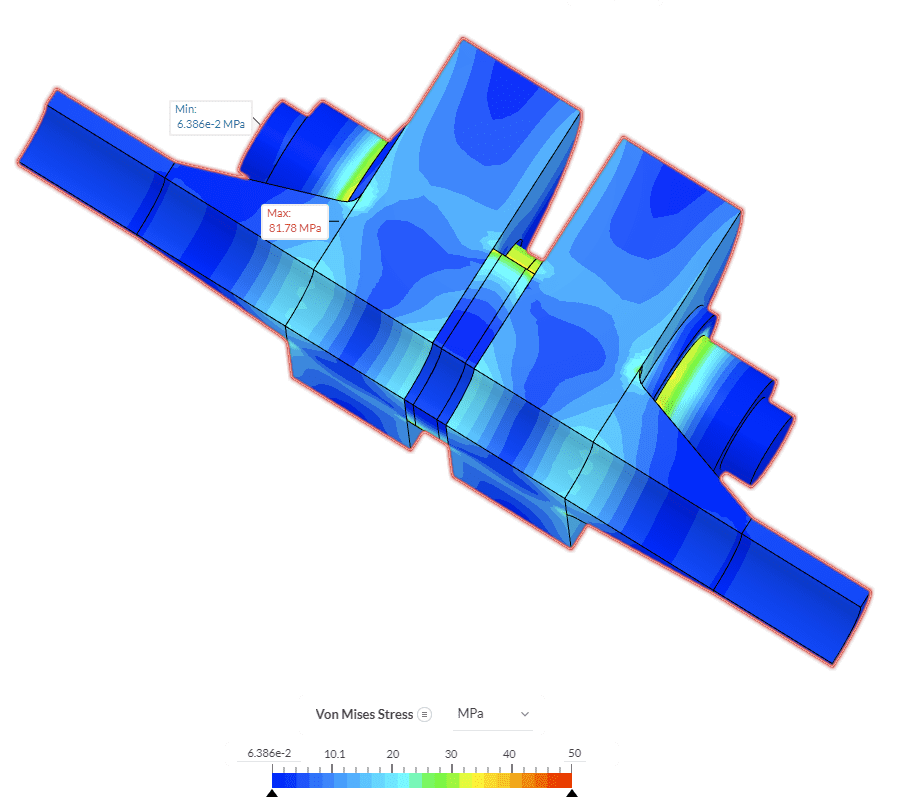

Illustration of the deformed shape and stress distribution on the flange under bolt preload condition is presented in Figure 3, while the overall distribution of the axial stress on the bolt \(\sigma_{ZZ}\) is presented in Figure 4:

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: March 1st, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now