Documentation

This validation case belongs to thermomechanics, with the case of a bimetallic strip under thermal load. The aim of this test case is to validate the following parameters:

The simulation results of SimScale were compared to theoretical computations derived from [Roark’s]\(^1\).

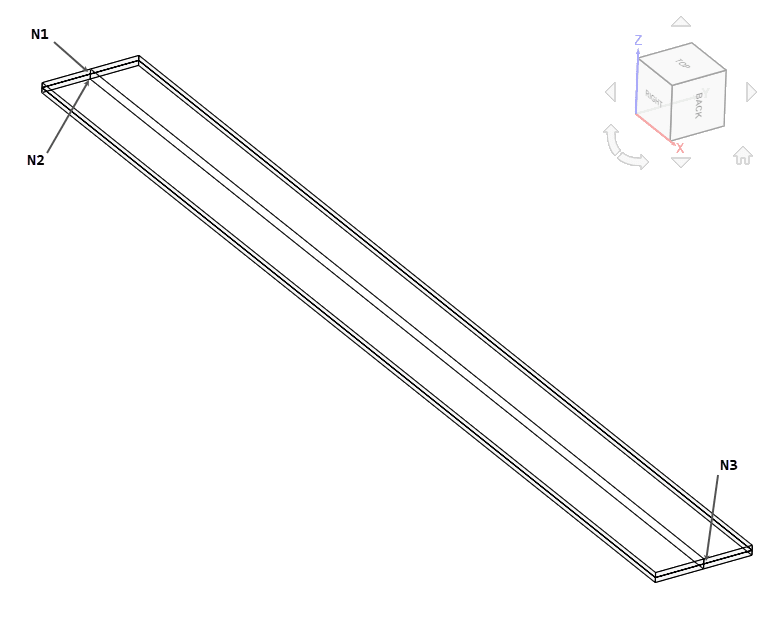

The geometry used for the case is as follows:

It represents a strip with length \(l\) of 10 \(m\), width \(w\) of 1 \(m\) and thickness \(t\) of 0.1 \(m\), composed of two strips each with thickness \(t_a , t_b\) of 0.05 \(m\). Nodes N1 and N3 are located at mid-thickness and node N2 is located at the bottom surface as shown in figure 1.

Tool Type: Code_Aster

Analysis Type: Thermomechanical steady state with static inertia effect

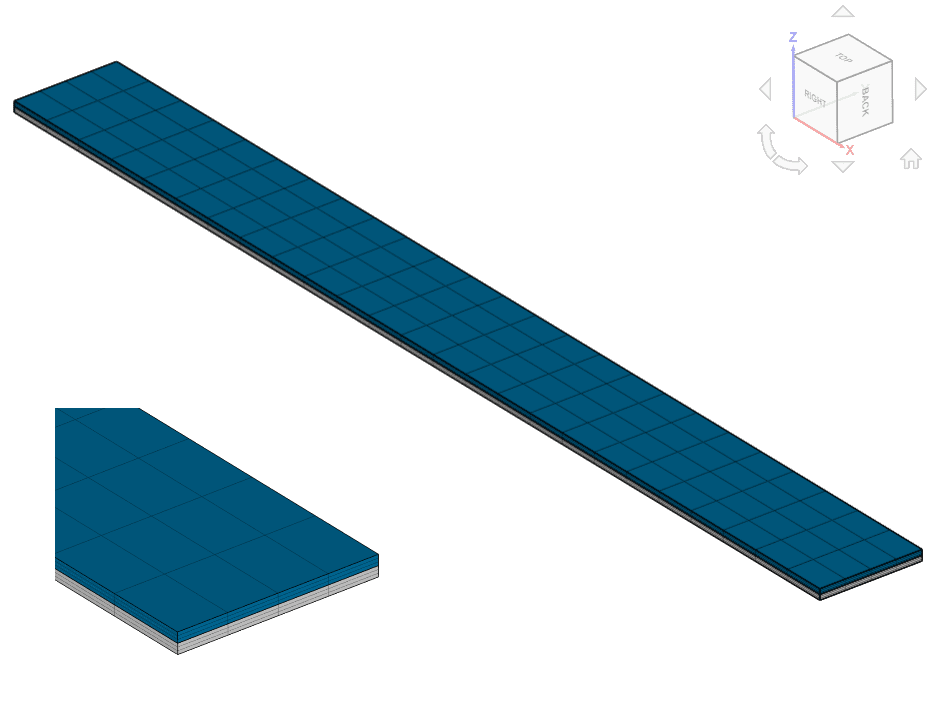

Mesh and Element Types:

| Mesh Type | Number of Nodes | Element Type |

|---|---|---|

| 2nd order hexahedral | 3652 | Standard |

The hexahedral mesh was computed locally and uploaded into the simulation project.

Material:

Boundary Conditions:

The reference solution is of the analytical type, as presented in [Roark’s]\(^1\). It is given in terms of the displacements of the free end of the strip and the stress at the bottom surface:

$$ d_x = l (T – T_0) \frac{\gamma_a + \gamma_b}{2} $$

$$ d_z = \frac{ 3 l^2 (\gamma_b – \gamma_a) (T – T_0)(t_a + t_b) }{ t_b^2 K_1} $$

$$ \sigma_{bottom} = \frac{ (\gamma_b – \gamma_a)(T – T_0) E_b }{ K_1 } \Big[ 3 \frac{t_a}{t_b} + 2 – \frac{E_a}{E_b} \Big( \frac{t_a}{t_b} \Big)^3 \Big] $$

$$ K_1 = 4 + 6 \frac{t_a}{t_b} + 4 \Big( \frac{t_a}{t_b} \Big)^2 + \frac{E_a}{E_b} \Big( \frac{t_a}{t_b} \Big)^3 + \frac{E_b}{E_a} \frac{t_b}{t_a} $$

The computed solutions are:

\(d_x= 0.015\ m\)

\(d_z = 0.75\ m\)

\(\sigma_{bottom} = 50\ MPa\)

A comparison of displacements at point N3 and stress \(\sigma_{XX}\) at point N2 with theoretical solution is presented below:

| POINT | FIELD | COMPUTED | REF | ERROR |

|---|---|---|---|---|

| N3 | DX \([m]\) | 0.015 | 0.015 | 0.00 % |

| N3 | DZ \([m]\) | 0.7479 | 0.75 | -0.28 % |

| N2 | SIXX \([MPa]\) | 48.7631 | 50 | -2.47 % |

Illustration of the deformed shape and stress distribution on the bimetallic strip below:

Advanced Tutorial: Thermomechanical Analysis of an Engine Piston

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: May 19th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now