Documentation

This validation case belongs to thermomechanics, with the case of a thick hollow thermoelastic cylinder under temperature gradient conditions. The aim of this test case is to validate the following parameters:

The simulation results of SimScale were compared to the analytical results presented in [HPLA100]\(^1\).

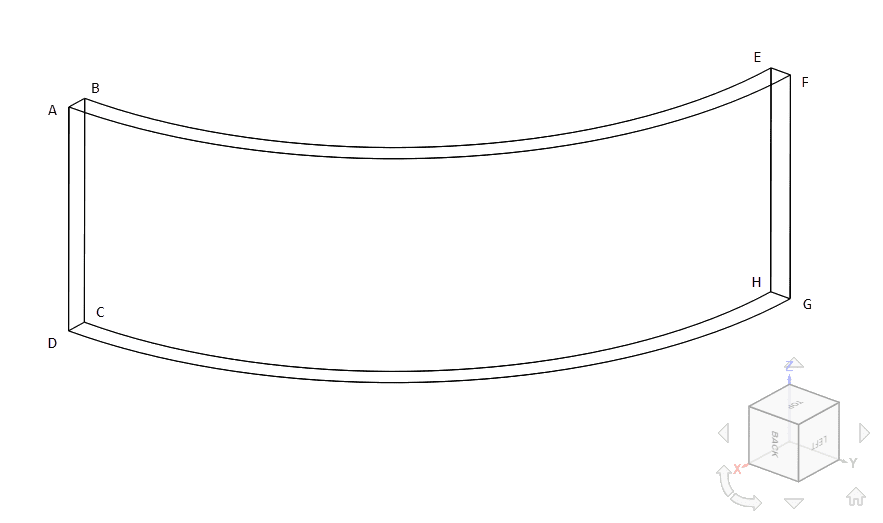

The geometry used for the case is as follows:

It represents a quarter section of a hollow cylinder with an internal radius of 19.5 \(m\) and an external radius of 20.5 \(m\), length of 10.0 \(m\). Face ABCD coincides with the XZ plane, face EFGH with the YZ plane and face CHGD with the XY plane.

Tool Type: Code_Aster

Analysis Type: Thermomechanical, Linear, Steady State.

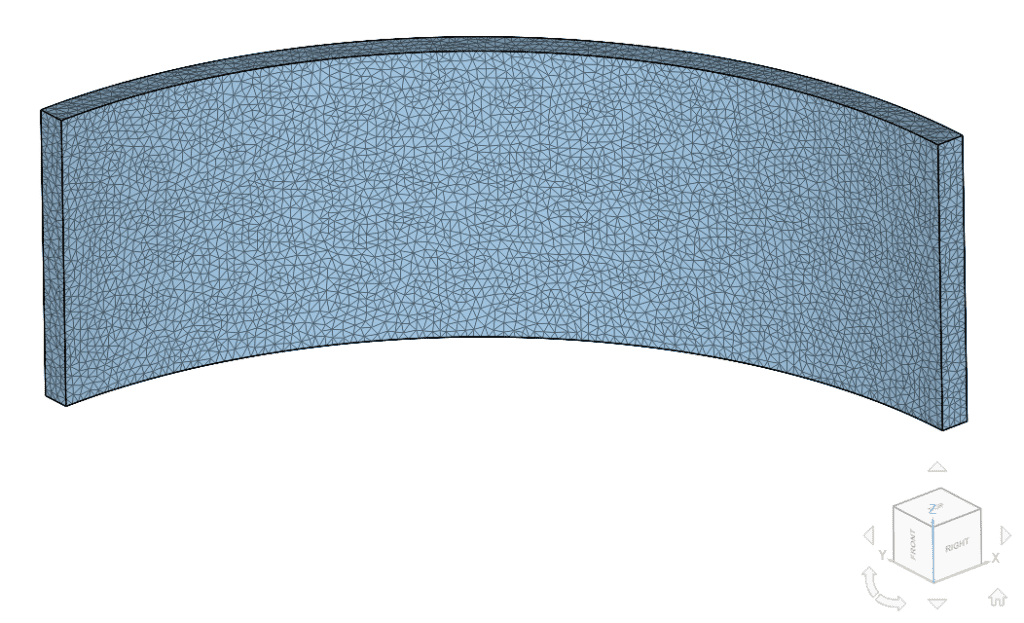

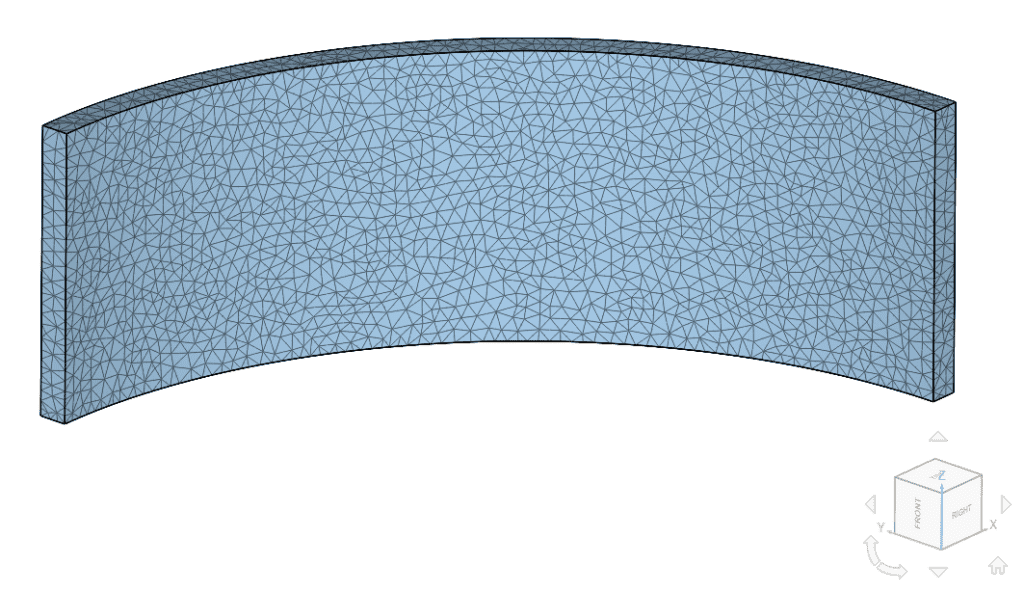

Mesh and Element Types:

| Case | Mesh Type | Number of Nodes | Element Type |

|---|---|---|---|

| A, B | 1st order tetrahedral | 22105 | Standard |

| C, D | 2nd order tetrahedral | 39674 | Standard |

The meshes were computed using SimScale’s standard mesh algorithm and automatic sizing.

Material:

Boundary Conditions:

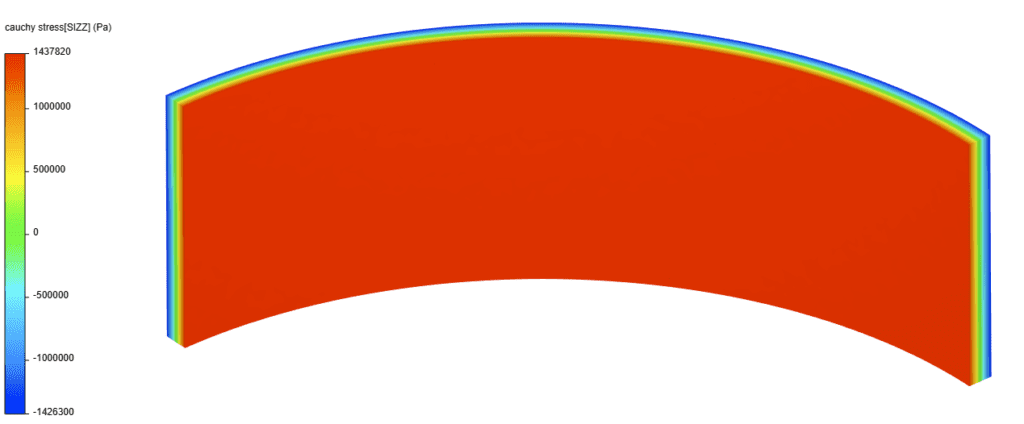

The reference solution for the thermoelastic cylinder is of the analytical type, as presented in [HPLA100]\(^1\). It is given in terms of the longitudinal stress onthe internal and external faces:

Cases A and C, internal face: \( \sigma_{ZZ}\) = 1.4321427 \( MPa \)

Cases A and C, external face: \( \sigma_{ZZ}\) = -1.4250001 \( MPa \)

Cases B and D, internal face: \( \sigma_{ZZ}\) = -0.2 \( MPa \)

Cases B and D, external face: \( \sigma_{ZZ} \) = -0.2 \( MPa \)

Comparison of the computed stresses with the reference solution is presented, at the representative points:

| CASE | POINT | SIMSCALE \( \sigma_{ZZ} \) \([Pa]\) | REFERENCE \( \sigma_{ZZ} \) \([Pa]\) | ERROR |

|---|---|---|---|---|

| A | C | 1.1593Ee6 | 1.4321e6 | 19.1 % |

| D | -1.1943e6 | -1.4250e6 | 16.2 % | |

| B | C | -2.0010e5 | -2.0e5 | 0.0 % |

| D | -1.9993e5 | -2.0e5 | 0.0 % | |

| C | C | 1.4342e6 | 1.4321e6 | -0.1 % |

| D | -1.4228e6 | -1.4250e6 | 0.2 % | |

| D | C | -2.0000e5 | -2.0e5 | 0.0 % |

| D | -2.0000e5 | -2.0e5 | 0.0 % |

It is found that general results agree with the reference solution. As usual, the first order tetrahedral mesh gives bad accuracy on the bending case, although for the pure expansion it gives good results. It is expected that a finer mesh will improve the accuracy of the solution.

Illustration of the stress distribution for the bending case of the thermoelastic cylinder is shown below:

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: September 30th, 2020

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now