Documentation

This thermal bridge validation case belongs to heat transfer. The aim of this test case is to validate the following parameters:

The simulation results of SimScale were compared to the results presented in EN ISO 10211 Standard, case 4.

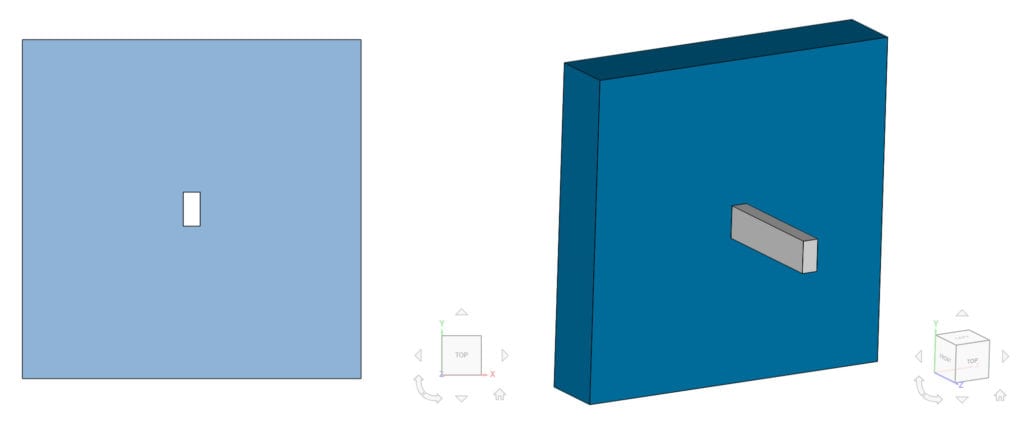

The 3D geometry for this project is a thermal bridge consisting of an iron bar penetrating an insulation layer, as seen in Figure 1:

The insulated wall consists of a block with a rectangular cross-section of 1×1 \(m\) and a width of 0.2 \(m\). The bar is placed vertically in the center of the wall and goes through the whole layer. It has a rectangular cross-section of 0.1×0.05 \(m\) and a total length of 0.6 \(m\), including its penetrated part.

Tool Type: Code_Aster

Analysis Type: Linear, steady-state heat transfer analysis

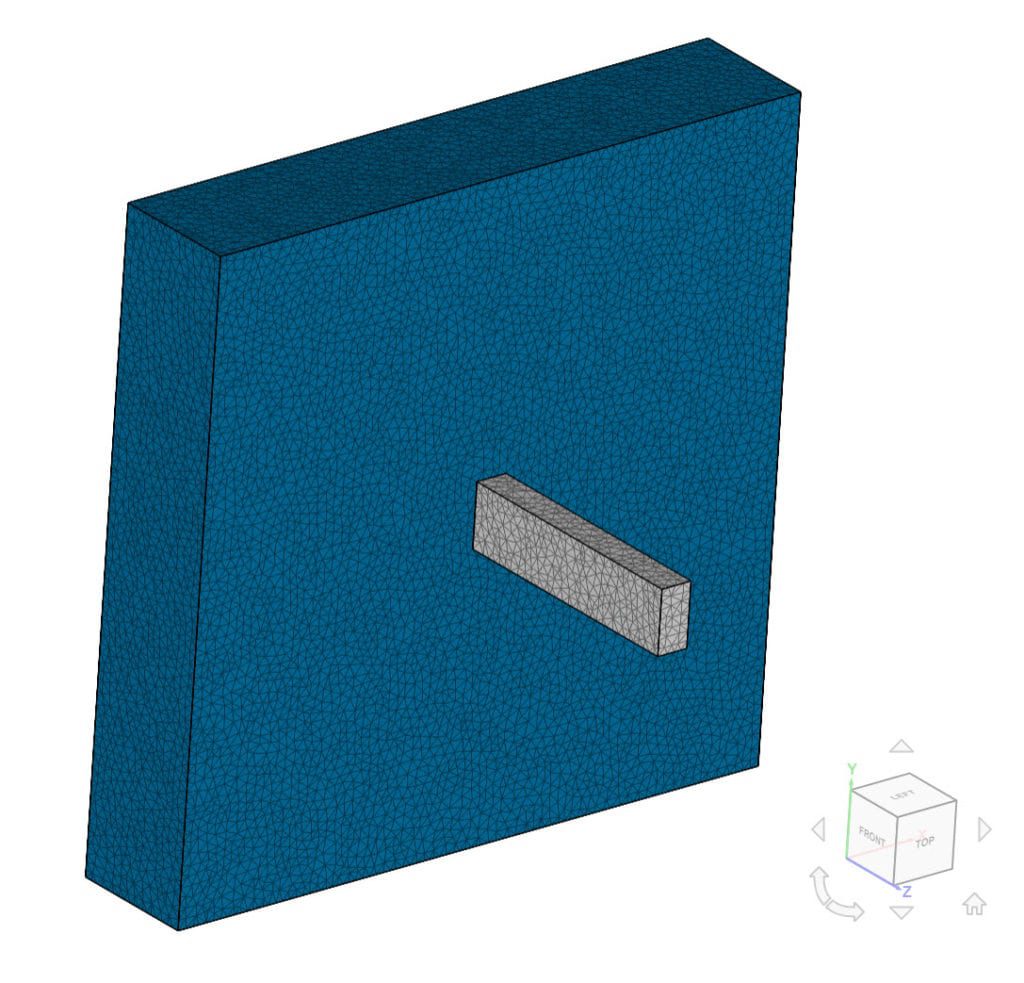

Mesh and Element Types: For this case, SimScale’s standard meshing algorithm was used, which generates a combination of tetrahedral and hexahedral cells. The characteristics of the resulting mesh can be seen below:

| Case | Mesh Type | Nodes | Cells | Element Type |

| EN ISO 10211 Case 4 | Second-order standard | 769105 | 553835 | Standard |

In the image below, it’s possible to see the standard mesh in detail:

Material:

Each body is assigned to a different material:

Boundary Conditions:

As shown in Figure, the following boundary conditions are defined:

The results obtained with SimScale were compared to those presented in [1]. The two criteria that must be satisfied are:

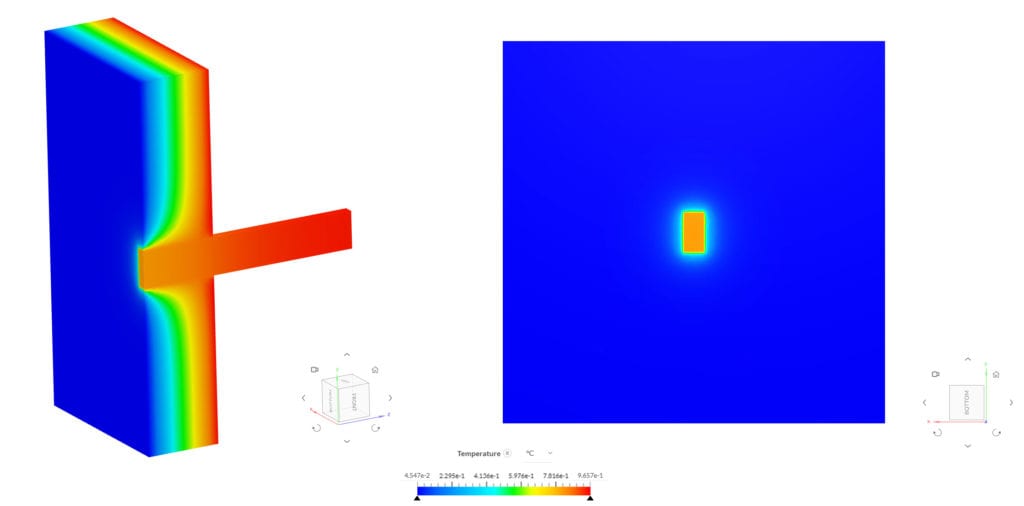

The bulk calculator feature provided in SimScale’s integrated post-processor was used to extract the maximum temperature of the beam’s end cross-section, which is coincident with the insulation layer. The Heat Flux was measured using the Heat Flow result control Item. The table below provides an overview of the results:

| Result | Reference Value | SimScale Result | Deviation |

|---|---|---|---|

| Maximum temperature on exterior | 0.805\(°C\) | 0.803\(°C\) | 0.002\(°C\) |

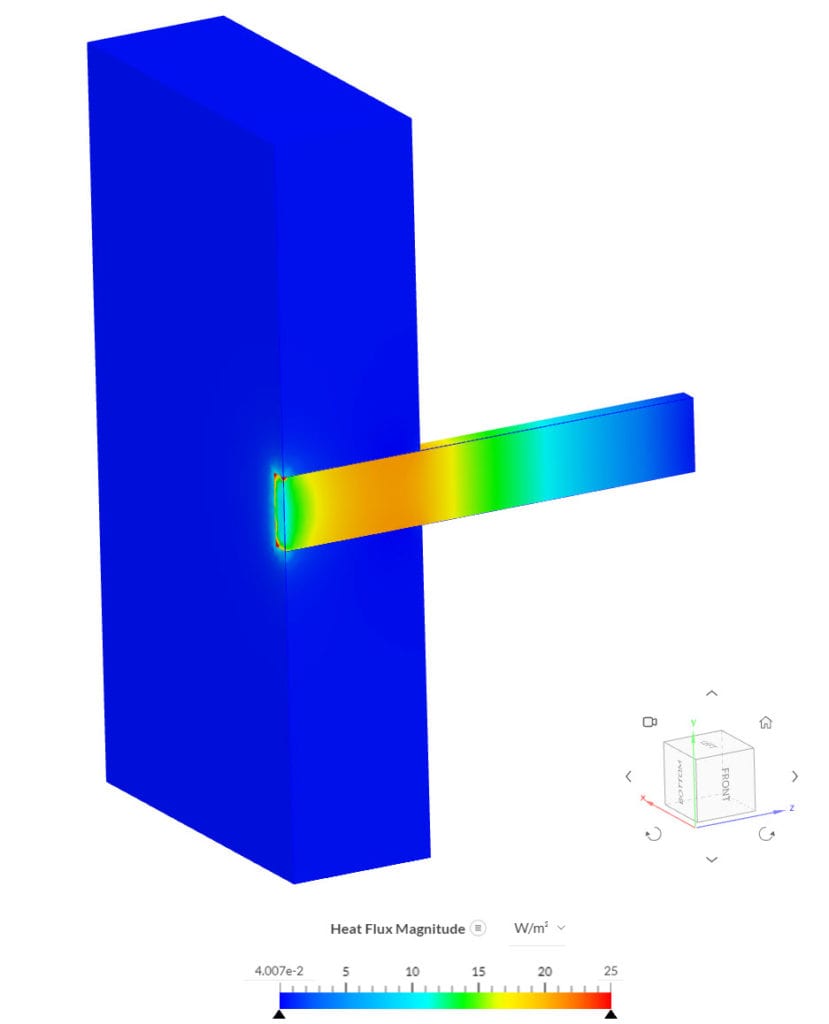

| Heat Flow | 0.540\(W\) | 0.542\(W\) | -0.37% |

Table 4 indicates a good agreement of the SimScale results with the reference paper, with a permitted difference between the extracted values and the standard.

Below you can see the results of the simulation, created in the online post-processor:

Additionally, the heat flux magnitude can be visualized on the cutting plane normal to the X axis too:

Last updated: August 30th, 2022

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now