Documentation

This validation case belongs to an elastoplastic impact in solid mechanics. The aim of this test case is to validate the following parameters:

The simulation results of SimScale were compared to the numerical results presented in [SDNV103]\(^1\).

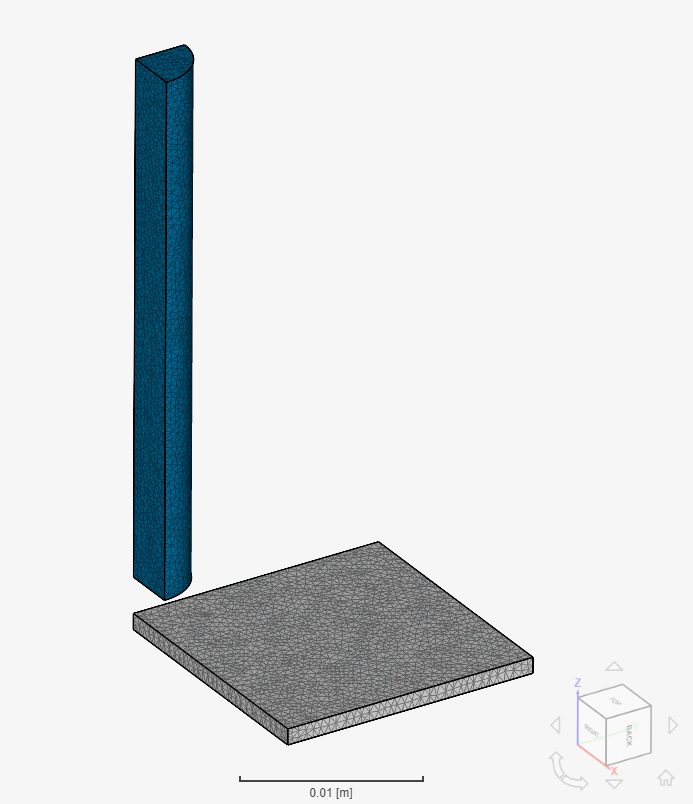

The geometry used for the case is as follows:

It represents an elastoplastic bar in the z-direction and a rectangular plate in the x-y plane with the following coordinates for each point:

| Point | X [m] | Y [m] | Z [m] |

|---|---|---|---|

| A | 0 | 0 | 0 |

| B | 0.016 | 0 | 0 |

| C | 0.016 | 0.016 | 0 |

| D | 0 | 0.016 | 0 |

| E | 0 | 0 | 0.001 |

| F | 0.016 | 0 | 0.001 |

| G | 0.016 | 0.016 | 0.001 |

| H | 0 | 0.016 | 0.001 |

| I | 0 | 0 | 0.00327 |

| J | 0.0032 | 0 | 0.00327 |

| K | 0 | 0.0032 | 0.00327 |

| L | 0 | 0 | 0.03567 |

| M | 0.0032 | 0 | 0.03567 |

| N | 0 | 0.0032 | 0.03567 |

Tool Type: Code Aster

Analysis Type: Dynamic

Mesh and Element Types: The meshes used in this project were created in SimScale with the standard algorithm. Manual refinements are used to control the cell sizes.

| Case | Element Type | Number of Nodes | Element Technology |

|---|---|---|---|

| A | 1st Order Tetrahedral | 10435 | Standard |

| B | 2nd Order Tetrahedral | 70001 | Reduced Integration |

Find below the mesh used for case B. It’s a standard mesh with second-order tetrahedral cells.

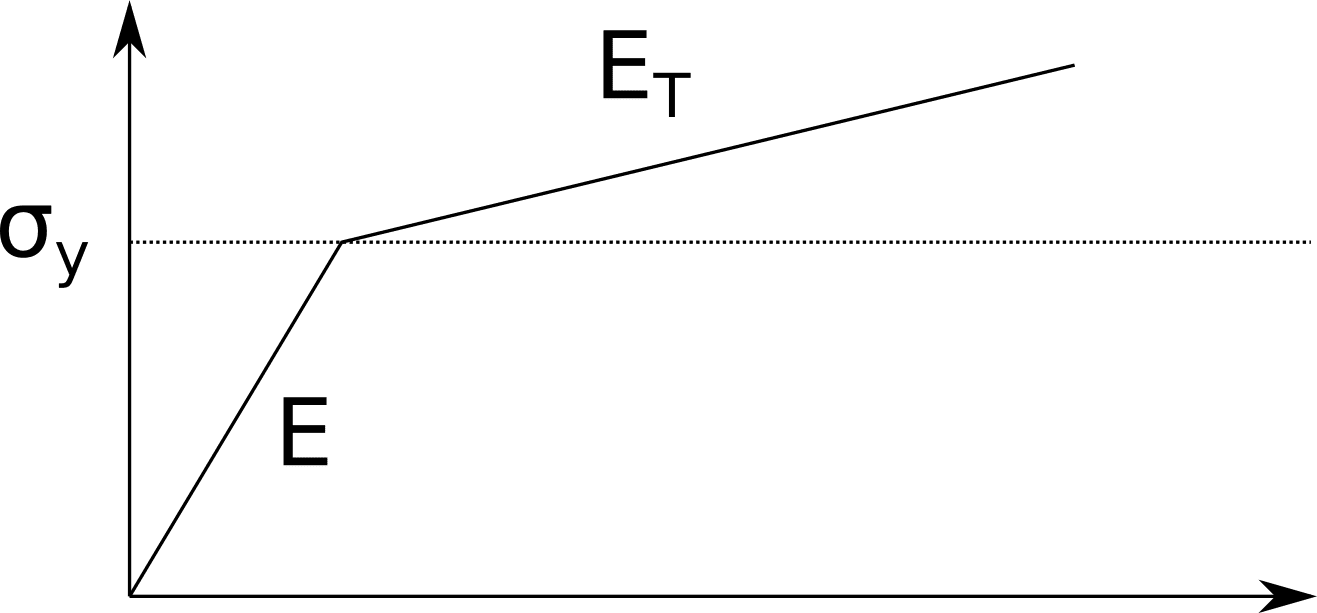

Material:

Boundary Conditions:

The reference solution is from a numerical computation as presented section 2 of [SDNV103]\(^1\), which are taken as the mean results of [Stainer]\(^2\):

\( DX_J = 3.87 mm \)

\( DZ_L = 13.46 mm \)

Comparison of displacements at points J (DX) and L (DZ) at time \( t = 9×10^{-5}\ s \):

| CASE | POINT | COMP | COMPUTED | REF | ERROR |

|---|---|---|---|---|---|

| A | J | DX | 0.00289 | 0.00387 | -25.4% |

| A | L | DZ | -0.01250 | -0.01346 | -7.1% |

| B | J | DX | 0.00365 | 0.00387 | -5.8% |

| B | L | DZ | -0.01265 | -0.01346 | -6.0% |

An illustration of the final shape (case B) can be found in Figure 4. The elastoplastic deformation due to the impact can be appreciated:

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: September 30th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now