Documentation

This case belongs to solid mechanics. The aim of this test case is to validate the following parameters within the components of an electronics design:

The simulation results of SimScale are compared to the results presented in [Bruce]

The geometry used for the case is as follows:

A more descriptive schematic of the components explains the configuration as shown in Figure 2:

The analysis is carried out on a high-power IC package that is attached between the heatsink base and the PCB substrate. The components explicitly represented in the simulation model are the die, TIM 1, lid, TIM 2, and the heat sink base (where TIM = Thermal Interface Material). These components are shown inside the dashed square box above.

The following table displays the dimensions of each component in the electronics design:

| Component | Length | Width | Thickness |

|---|---|---|---|

| Die | 13 | 13 | 0.50 |

| TIM 1 | 13 | 13 | 0.10 |

| Lid | 13 | 13 | 0.50 |

| TIM 2 | 13 | 13 | 0.05 |

| Heat sink base | 13 | 13 | 6.00 |

Tool type: Code_Aster

Analysis type: Heat transfer, Non-linear

Time dependency: Transient

Mesh and element types: SimScale’s Standard algorithm was used to generate the mesh for the electronics design.

| Meshing algorithm | No. of nodes | No. of volumes | Mesh Elements |

|---|---|---|---|

| Standard | 38694 | 184359 | Tetrahedral/Hexahedral |

The final mesh can be seen below:

Material:

| Component | Material | Thermal conductivity | Density | Specific heat |

|---|---|---|---|---|

| Die | Silicon | 111 | 2330 | 668 |

| TIM1 | Ag-Epoxy | 2.0 | 4400 | 400 |

| Lid | Copper | 390 | 8890 | 385 |

| TIM2 | Grease Aluminium filler particle | 1.0 | 2500 | 900 |

| Heat sink base | Copper | 390 | 8890 | 385 |

Initial conditions:

Boundary conditions:

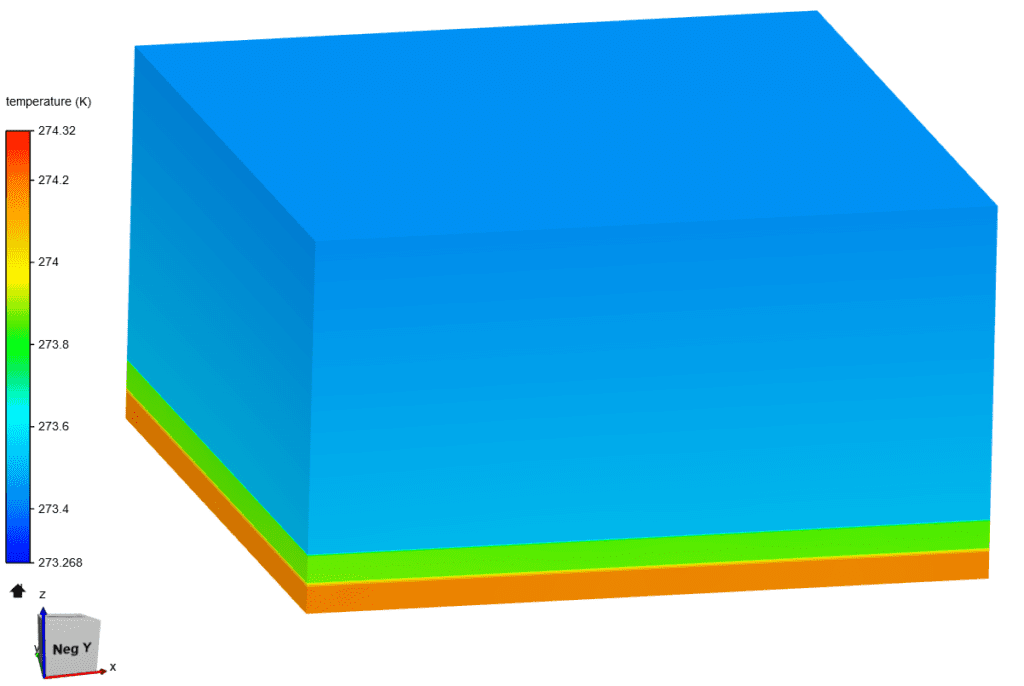

The temperature distribution of the IC package is as shown below:

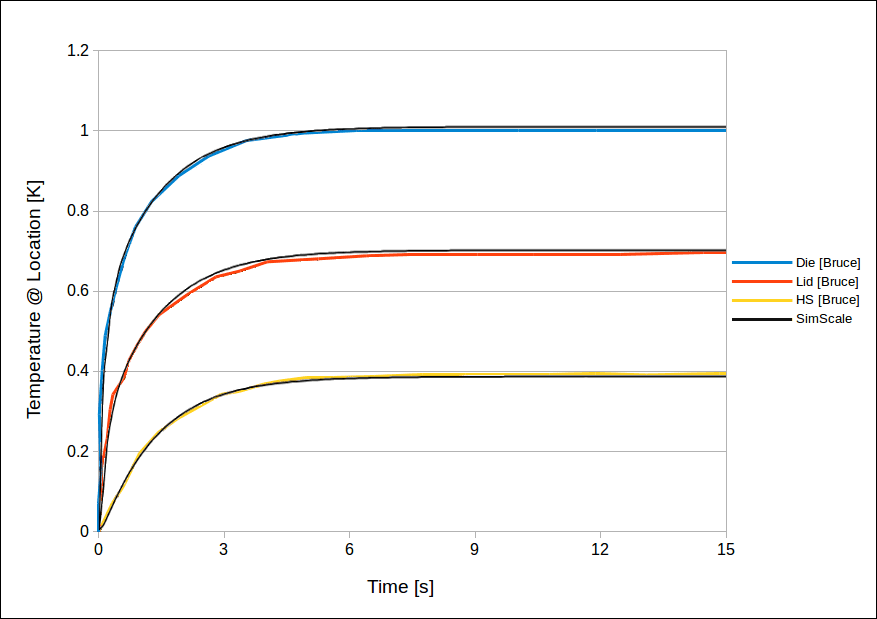

The comparison of SimScale results with that of [Bruce]

The results are calculated by deducting the initial temperature condition of 273.15

A slight deviation in the temperature graphs comparison above is due to the approximation error caused during the extraction of temperature values from the digital plots.

Last updated: May 20th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now