Documentation

This validation case belongs to solid mechanics. It aims to validate the following parameters:

The simulation results of SimScale were compared to the reference values presented in [SSNP123]\(^1\).

Find below the notched plate geometry used for this validation case:

The plate dimensions are tabulated below:

| A | B | C | D | E | F | |

| x | 0 | 0.004 | 0.005 | 0.005 | 0 | 0 |

| y | 0 | 0 | 0.001 | 0.005 | 0.005 | 0.001 |

| z | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

The corresponding nodes marked with an apostrophe (‘) are translated 0.0001 \(m\) along the negative z-direction.

Tool Type: Code_Aster

Analysis Type: Nonlinear static

Mesh and Element Types: The meshes used in this project were created in SimScale with the standard algorithm.

| Case | Element Type | Number of Nodes | Element Technology |

| (A) | 2nd Order Tetrahedral | 44211 | Standard |

| (B) | 2nd Order Tetrahedral | 44211 | Reduced integration |

Find below the mesh used for cases A and B. It’s a standard mesh with second-order tetrahedral cells.

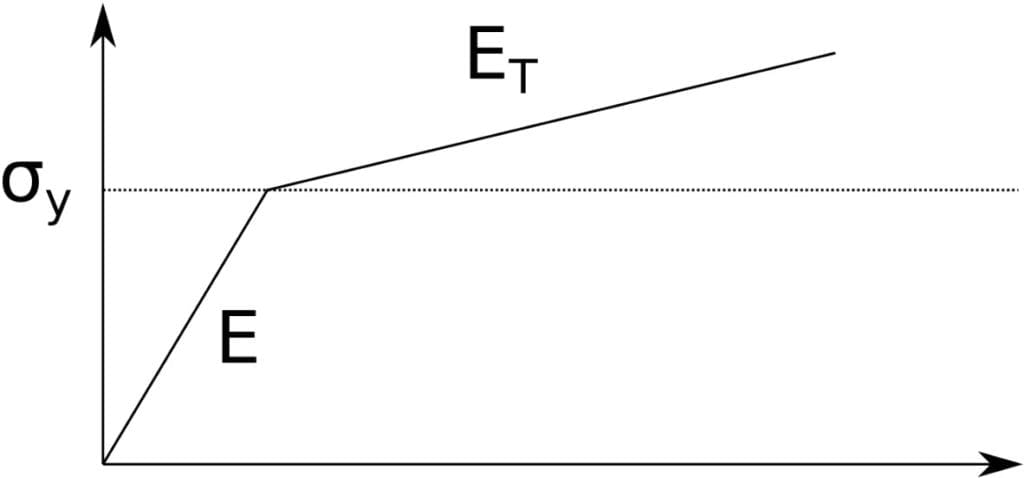

Material:

Boundary Conditions:

The results obtained from SimScale for the Cauchy stress \(\sigma_{yy}\) along the FC line are compared to the values of reference from [SSNP123]\(^1\). These values of reference were extracted with WebPlotDigitizer. Figure 5 shows the results for case A, where element technology is set to standard:

Similarly, for case B, where reduced integration was used:

In both Figures 5 and 6, SimScale’s results show good agreement with the reference values.

Inspecting the Cauchy stress \(\sigma_{yy}\) for case B in the post-processor:

Last updated: November 7th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now