Documentation

This bonded contact validation case belongs to solid mechanics. This test case aims to validate the following parameter:

The simulation results obtained with SimScale were compared to the analytical results presented in [Roark]\(^1\).

Two geometries are used for this bonded contact validation. The first one consists of a quarter shaft. Radius is 0.1 \(m\) and length is 0.5 \(m\):

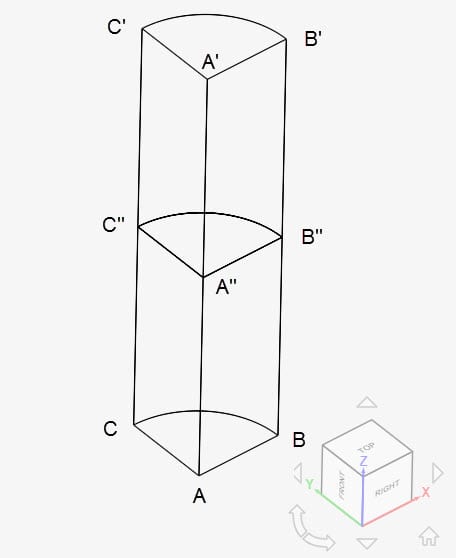

The second geometry has the same dimensions, however, it is split exactly in half, between the ABC and A’B’C’ planes:

The 3D geometry is a 90\(^0\) section of a cylinder with dimensions as tabulated below:

| A | B | C | A’ | B’ | C’ | A” | B” | C” | |

| x | 0 | 0.1 | 0 | 0 | 0.1 | 0 | 0 | 0.1 | 0 |

| y | 0 | 0 | 0.1 | 0 | 0 | 0.1 | 0 | 0 | 0.1 |

| z | 0 | 0 | 0 | 0.5 | 0.5 | 0.5 | 0.25 | 0.25 | 0.25 |

Tool Type: Code Aster

Analysis Type: Linear static

Mesh and Element Types: The meshes for Cases A through D were created in SimScale. The standard algorithm was used.

| Case | Geometry | Element Type | Number of Nodes | Element Technology |

| (A) | Quarter Shaft | 1st Order Tetrahedral | 8660 | Standard |

| (B) | Quarter Shaft – Split | 1st Order Tetrahedral | 8846 | Standard |

| (C) | Quarter Shaft | 2nd Order Tetrahedral | 62943 | Reduced Integration |

| (D) | Quarter Shaft – Split | 2nd Order Tetrahedral | 63772 | Reduced Integration |

Find below the mesh used for Case D. It is a standard mesh with second-order tetrahedral cells.

Material:

Boundary Conditions:

The analytical solution for maximum shear stress \(\tau_{max}\) given below is based on Roark\(^1\).

$$\large{\tau _{max}}=\frac {\theta.G.r}{l} = 3.2 \ [MPa]$$

The results obtained from SimScale for the maximum shear stress \(\tau_{max}\) at point B’ are compared with the analytical solution by [Roark].

| Case | Quantity | Roark | SimScale | Error (%) |

| (A) | Maximum shear stress \(\tau_{max} [MPa]\) | 3.2 | 3.209 | +0.289 |

| (B) | Maximum shear stress \(\tau_{max} [MPa]\) | 3.2 | 3.191 | -0.279 |

| (C) | Maximum shear stress \(\tau_{max} [MPa]\) | 3.2 | 3.195 | -0.152 |

| (D) | Maximum shear stress \(\tau_{max} [MPa]\) | 3.2 | 3.180 | -0.639 |

Inspecting the Cauchy stress magnitude for Case B in the post-processor:

References

Last updated: November 7th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now