Documentation

This validation case falls under the domain of fluid mechanics, specifically addressing the aerodynamic characteristics of the Ahmed body. The objective of this study is to assess and validate the following parameters by employing the Incompressible Lattice Boltzmann Method (LBM) by Pacefish®\(^2\):

The simulation results from SimScale were compared to the experimental data presented in the study: S.R. Ahmed, G. Ramm, Some Salient Features of the Time-Averaged Ground Vehicle Wake, SAE-Paper 840300, 1984\(^1\)

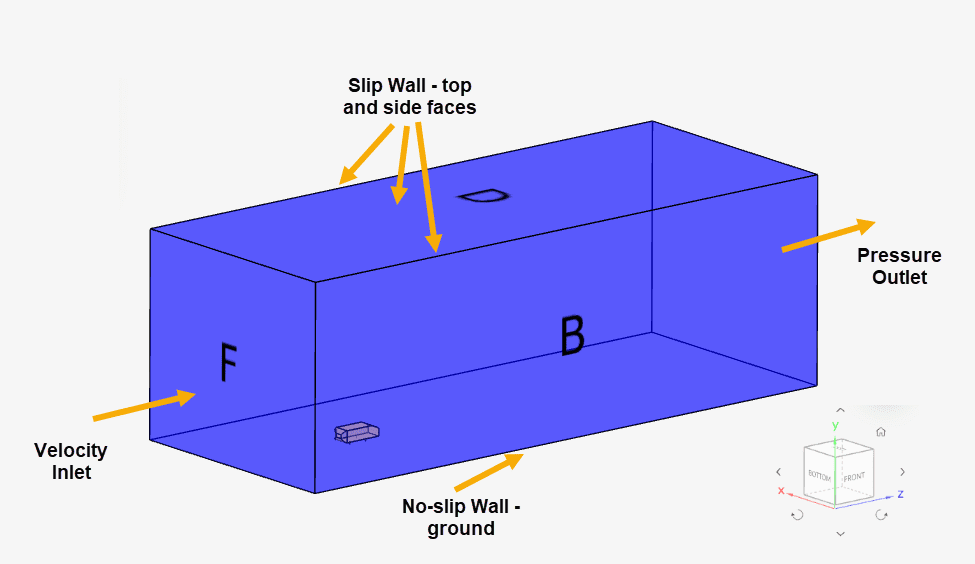

The geometry is created based on the simplified aerodynamic body used by Ahmed et al\(^1\). See Figure 1 for dimensions and Figure 2 for the geometry. The slant angle (\(\phi\)) is set to 25°. The body is placed in a wind tunnel 6 \(m\) x 5 \(m\) x 13.5 \(m\) in order to limit the aerodynamic blockage effect.

Tool Type: Lattice Boltzmann Method (LBM) (Pacefish\(^®\) by Numeric Systems GmbH)

Analysis Type: Transient, Incompressible flow with K-Omega SST turbulence model

Mesh and Element Types:

In order to get accurate results, manual mesh settings were applied. The mesh algorithm uses the lattice Boltzmann method, where a Cartesian background mesh is generated, composed only of cube elements that are not necessarily aligned with the geometry of the buildings or the terrain. (see Figures 3 and 4).

Three meshes were computed in increasing order of fineness to compute and match the values of drag force with the study\(^1\).

The mesh density was consciously increased such that the background mesh remained at the same coarse level, while the surface and region refinements around the car were progressively added. The details are shown in Table 1.:

| Mesh | Background mesh (Manual) | Car surface Refinement \([m]\) | Region Refinement 1 \([m]\) | Region Refinement 2 \([m]\) | Number of Cells |

|---|---|---|---|---|---|

| Mesh 1 | Very Coarse | 0.005 | 0.015 | 0.02 | 21 282 816 |

| Mesh 2 | Very Coarse | 0.002 | 0.01 | 0.02 | 50 016 640 |

| Mesh 3 | Very Coarse | 0.0008 | 0.006 | 0.02 | 182 706 176 |

Note

Further mesh refinements were discarded due to extremely high mesh cell count and no improvement in the drag force value observed.

Fluid

When using the LBM solver, the boundary conditions are assigned on the faces of the flow domain.

The boundary conditions for the simulation are shown in Figure 5 below:

Details of the applied boundary conditions are further discussed below:

| Face | Boundary Condition | Value |

| F | Velocity inlet – Fixed Magnitude Turb. kinetic energy Specific dissipation rate | 60 \([m/s]\) 0.135 \([m^2/s^2]\) 180.1 \([1/s]\) |

| E | Pressure Outlet | – |

| A, B, D | Slip Wall | – |

| C | No-slip Wall |

The free stream velocity of the simulation is 60 \(m/s\), so that the Reynolds number based on the length of the body \(L\) is 4.29e6. Those are the same values presented in the original experiment of Ahmed and Ramm\(^1\).

The simulation is transient in nature and was run to simulate a real time of 0.4 seconds. This ensures that the air flow passes a ~2 times over the Ahmed body, given the flow domain size, and the inlet velocity. Due to the stable nature of the solution, longer times were discarded to save computational expenses.

The experimental solution is presented in Figure 4 in the reference paper\(^1\), giving the value for the drag force coefficient for the slant angle \(\phi\) = 25°:

$$ C_{d} = 0.2875 $$

The drag force is defined as

$$ F_{d}={\frac {1}{2}}\rho \,U^{2}\,C_{d}\,A_x $$

where \(A_x\) (0.115 \(m^2\)) is the projected area of the Ahmed body in the streamwise direction and \(F_{d}\) the drag force. The drag force and drag coefficient were determined by the integration of surface pressure and shear stress over the entire Ahmed body (except for the 4 stilts acting as support).

The resulting drag coefficient of the Ahmed body, closest to the reference solution as yielded by Mesh 3, was computed to be 0.2997, which is within a 4.71 % error margin of the experimental value.

Table 2 shows the result of the mesh independence study:

| Mesh | DRAG FORCE \([N]\) | DRAG COEFFICIENT | REFERENCE | ERROR [%] |

|---|---|---|---|---|

| Mesh #1 | 94.31 | 0.3879 | 0.2875 | 32.5 |

| Mesh #2 | 76.66 | 0.3096 | 0.2875 | 7.7 |

| Mesh #3 | 74.53 | 0.2997 | 0.2875 | 4.71 |

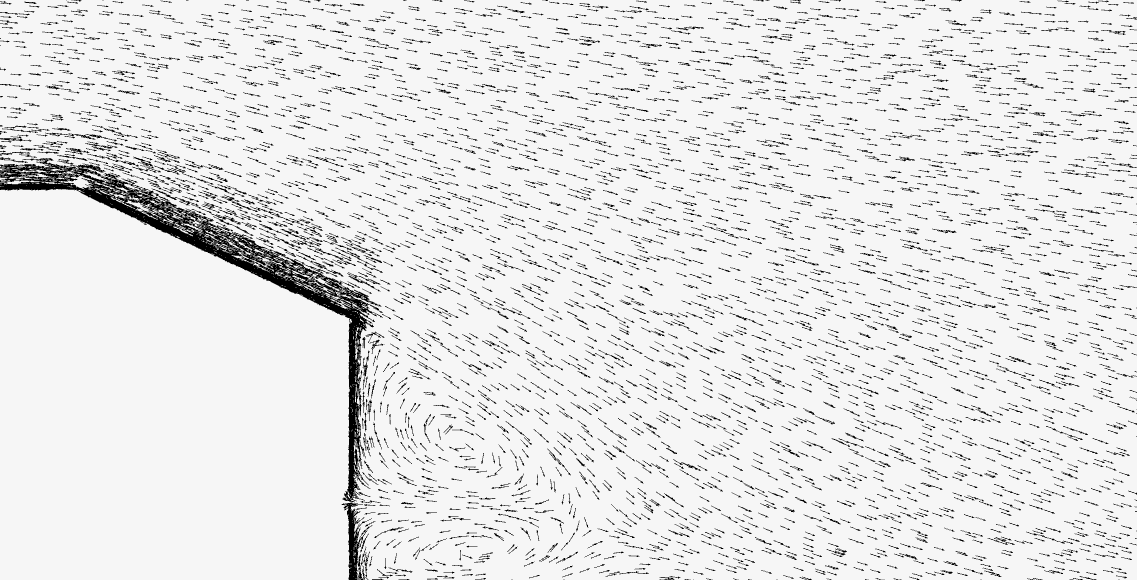

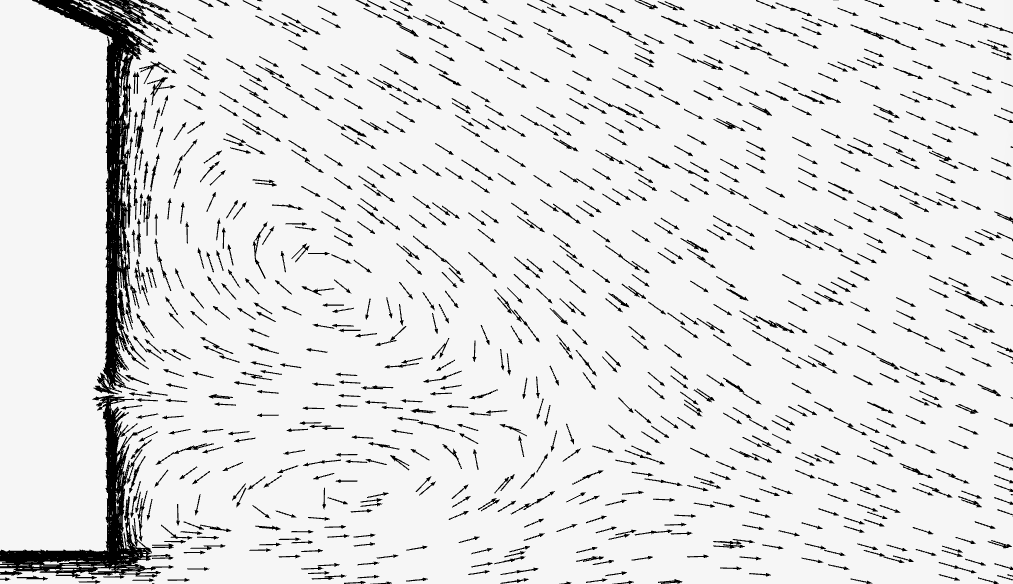

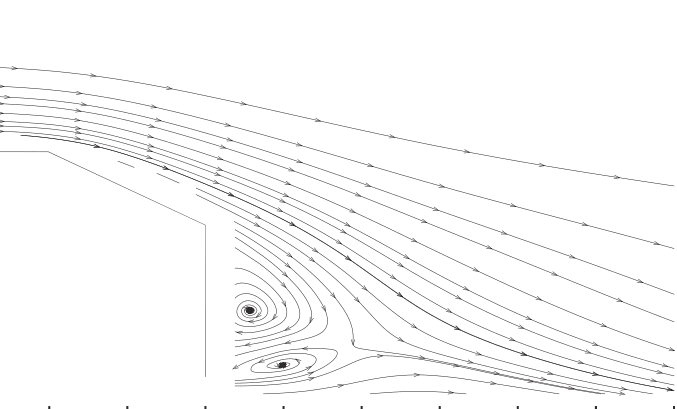

The velocity streamline contour of the mean flow obtained with the simulation is reported in Figures 6 and 7, together with experimental results for reference in Figure 8.

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: December 2nd, 2025

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now