To set a successful Conjugate Heat Transfer (CHT) simulation, make sure that the minimum requirements are met as seen in the following figure:

SimScale helps you to ensure a successful simulation by highlighting them with the green check![]() in the simulation setup. To ensure a successful CHT simulation and acceptable results, read the checklist below for our best practices:

in the simulation setup. To ensure a successful CHT simulation and acceptable results, read the checklist below for our best practices:

Best Practices

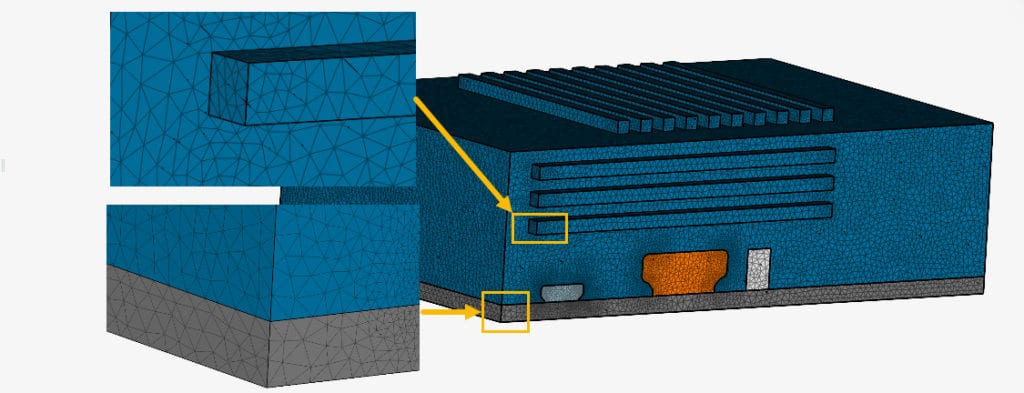

Mesh Quality

Create a mesh with sufficient number of elements:

- Confirm enough elements in the gaps. This will depend on how important the gap is considering the whole flow geometry. If the influence of the gap is not significant, then 2 or 3 elements are enough.

- Ensure a minimum of 2 or 3 elements through the heat transfer thickness of a solid. For example, add 3 elements through the thickness of a PCB board.

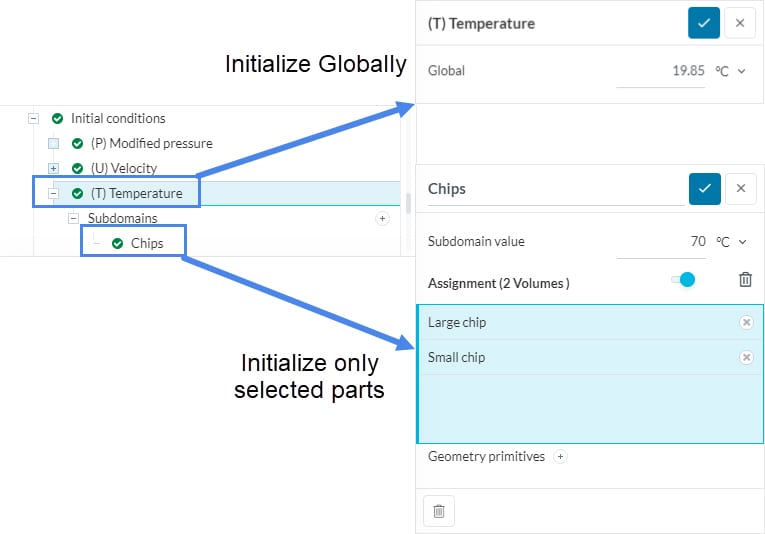

- Use the ‘Mesh log’ to check the most important mesh quality parameters and try to keep the mesh quality metrics below 20.

3. Direction of Gravity

The direction of gravity heavily influences a successful CHT simulation, therefore, check the Model settings to ensure that gravity is defined. Also, keep in mind that you should use the global coordinate system as a reference to define the direction of gravity.

4. Check the CAD Model

- Solid parts should not overlap or intersect.

- Some CAD models have manufacturing tolerances. Ensure the model to be free of such gaps and if you expect a contact between the parts, there should not be any gaps between the surfaces.

Here is a guide on how you can prepare your model for a simulation in SimScale.

5. Boundary Conditions

- Use Flow rate or Fixed value to define the flow rate or velocity of the flow.

- Use the Natural convection inlet-outlet boundary condition (BC) to define the outlet conditions.

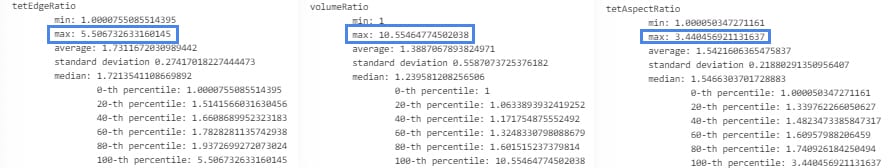

6. Check Fluid Properties

Fluid properties are an important part of a CHT simulation and this will heavily determine the results of the simulation.

- If you are applying a gas (e.g., air), then you can use the ‘Perfect gas’ equation.

- If you are using a liquid (e.g., water), then choose the ‘Rho constant equation of state fluids constant transport’ option and specify the fluid density manually.

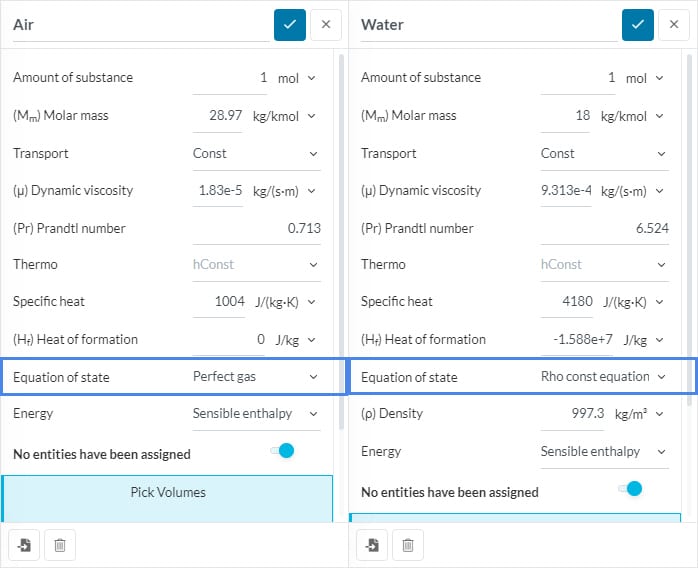

7. Initialize the Domain

Steady-state simulations are used to find out the state where the system has a balance with its environment, thus nothing changes anymore. For example, what is the temperature of the CPU in infinite time?

In steady state simulations, we are targeting to find the final state. Therefore, initial conditions define the final state. For example, the final temperature the CPU can reach in infinite time.

If you have an estimate of the temperatures of the solid components, this can help to accelerate convergence. You can follow the steps below to initialize the temperature of your domain:

- You can do this by going to Initial conditions.

- Fluids → Initialize with the inlet temperature of the fluid.

- Solids → Initialize the temperature with respect to your guess regarding the final temperature of the components.

Note

If none of the above suggestions solved your problem, then please post the issue on our forum or contact us.