Documentation

This design analysis of a spherical pressure vessel validation case belongs to thermomechanics. This test case aims to validate the following parameters:

The simulation results of SimScale were compared to the analytical results presented in [Afkar]\(^1\).

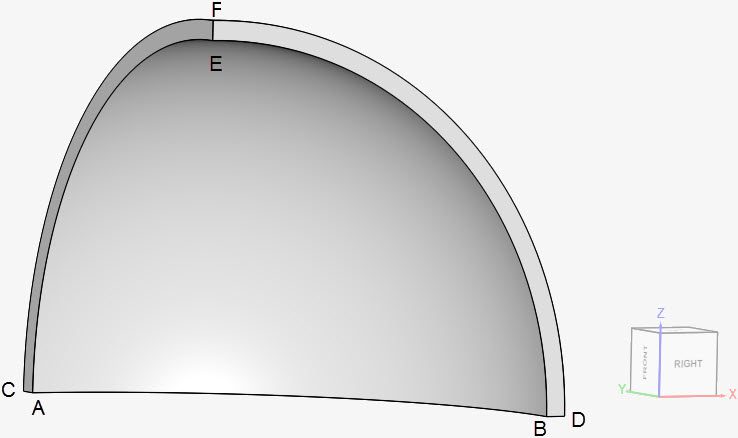

The geometry consists of 1/8th of a sphere, with an inner radius of 0.19 \(m\) and an outer radius of 0.2 \(m\).

The coordinates for the points in the sphere are as tabulated below:

| A | B | C | D | E | F | |

| x | 0 | 0.19 | 0 | 0.2 | 0 | 0 |

| y | 0.19 | 0 | 0.2 | 0 | 0 | 0 |

| z | 0 | 0 | 0 | 0 | 0.19 | 0.2 |

Tool Type: Code_Aster

Analysis Type: Transient thermomechanical, linear

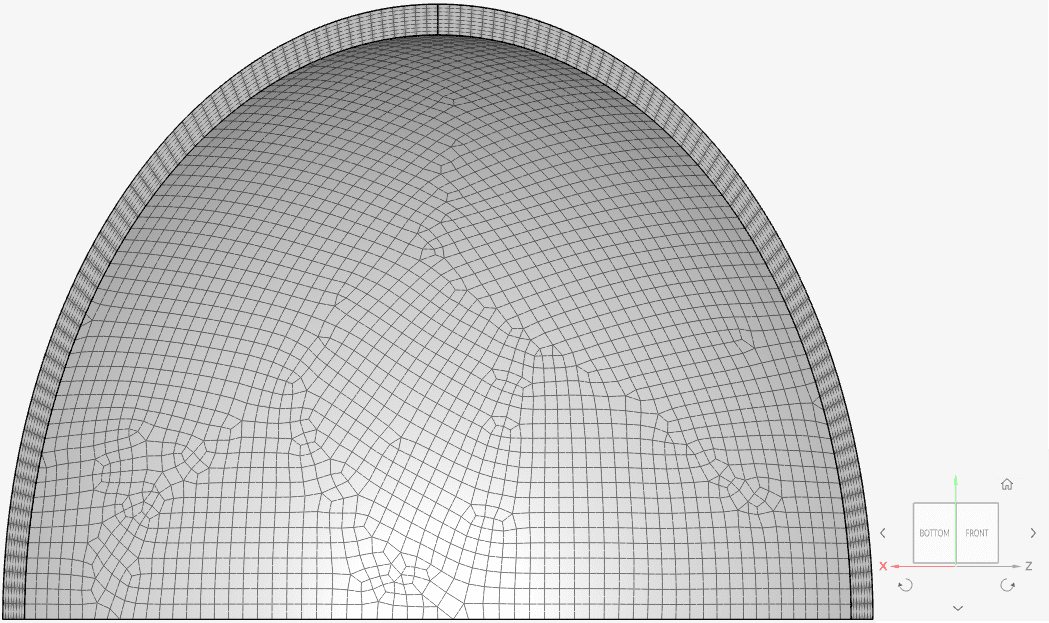

Mesh and Element Types: The mesh for cases A and B was created with the standard algorithm coupled with a quad-dominant extrusion refinement along the thickness of the vessel. A second order mechanical element and first order thermal element with lumped mass were considered.

The setup from cases A and B is the same, except for the thermal conductivity \(\kappa\).

| Case | Mesh Type | Nodes | Thermal Conductivity \(\kappa\) | Element Type |

| (A) | 2nd order Standard | 87962 | 20 \([\frac {W}{m.K}]\) | Hex-dominated |

| (B) | 2nd order Standard | 87962 | 22 \([\frac {W}{m.K}]\) | Hex-dominated |

Find below the mesh used for both cases. It’s a standard mesh with second order hexahedral-dominant elements.

Material:

Initial Conditions

Temperature is 300 \(K\) in the entire pressure vessel.

Boundary Conditions:

The analytical solution is given by the equations presented in [Afkar]\(^1\).

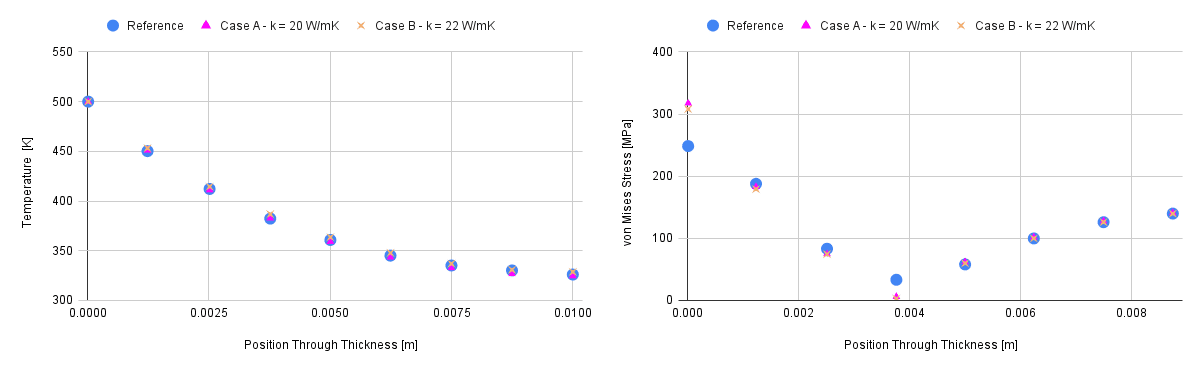

Since no value for thermal conductivity \(\kappa\) was provided, the values of 20 \(\frac {W}{m.K}\) and 22 \(\frac {W}{m.K}\) were used. For the final time step, the SimScale results for von Mises stress \([MPa]\) and temperature \([K]\) over the edge EF are compared to those from [Afkar]\(^1\).

In Figure 4, we can see how temperature is changing in the sphere’s width, for the last time step:

Last updated: September 26th, 2025

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now