Documentation

This 3D punch contact validation case belongs to solid mechanics. This test case aims to validate the following parameters:

The simulation results of SimScale were compared to the analytical results derived from [NAFEMS_R94]\(^1\).

The geometry consists of a punch (DGHIJK) on top of a foundation (ABCDEF). The 3D punch has a 10 \(mm\) radius fillet at the edge of the contact with the foundation. Figure 1 shows a wireframe of the geometry:

Due to the symmetry of the problem, only a quarter of the model is used for the simulations. These are the coordinates for each of the points:

| A | B | C | D | E | F | G | H | I | J | K | |

| x \([mm]\) | 0 | 0 | 0.1 | 0 | 0 | 0.1 | 0 | 0.04 | 0 | 0 | 0.05 |

| y \([mm]\) | -0.2 | -0.2 | -0.2 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0.1 | 0.1 |

| z \([mm]\) | 0 | 0.1 | 0 | 0 | 0.1 | 0 | 0.4 | 0 | 0 | 0.5 | 0 |

The following dimensions are used in the creation of the geometry:

| Geometry Feature | Dimension \([mm]\) |

| Punch diameter | 100 |

| Punch height | 100 |

| Foundation diameter | 200 |

| Foundation height | 200 |

| Fillet radius at the edge of the punch contact | 10 |

Tool Type: Code_Aster

Analysis Type: Dynamic

Mesh and Element Types: The meshes used in this project were created in SimScale with the standard algorithm.

| Case | Element Type | Nodes | Element Technology | Solution Method | Contact Smoothing | Penalty Coefficient | Coefficient of Friction |

| A | 1st Order Tetrahedral | 32101 | Standard | Penalty | On | 1e14 | 0 |

| B | 2nd Order Tetrahedral | 50226 | Reduced Integration | Penalty | On | 1e14 | 0 |

| C | 1st Order Tetrahedral | 32101 | Standard | Penalty | On | 1e14 | 0.1 |

| D | 2nd Order Tetrahedral | 50226 | Reduced Integration | Penalty | On | 1e14 | 0.1 |

Find below the mesh used for cases B and D. It’s a standard mesh with second-order tetrahedral cells.

Material:

Boundary Conditions:

Comparison of the displacements and the normal pressure of the nodes on edge DE. The values of reference in all figures were calculated with MSC.MARC and extracted from [NAFEMS_R94]\(^1\) with WebPlotDigitizer.

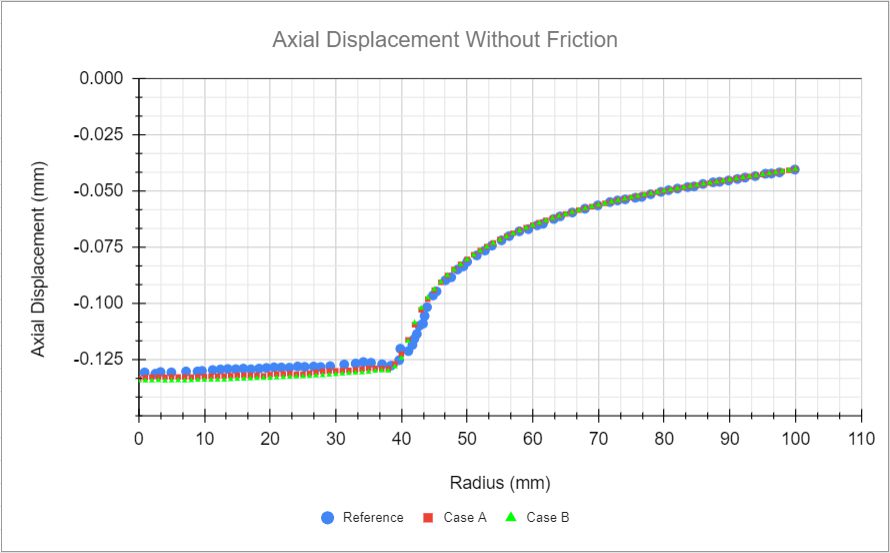

The first plot is a comparison between the axial displacements from the cases without friction and the reference values:

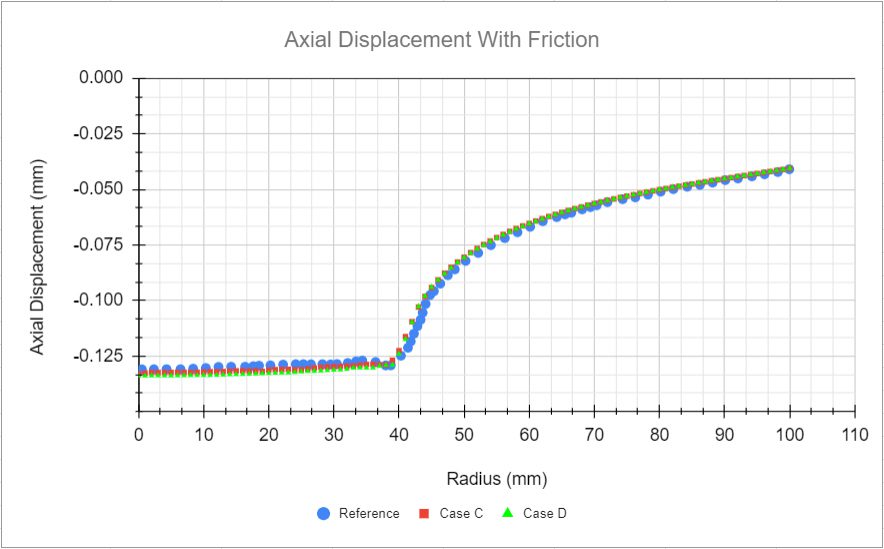

Now, comparing axial displacement from the cases with the friction and the reference values. Similarly to the previous case, a very good agreement is observed here:

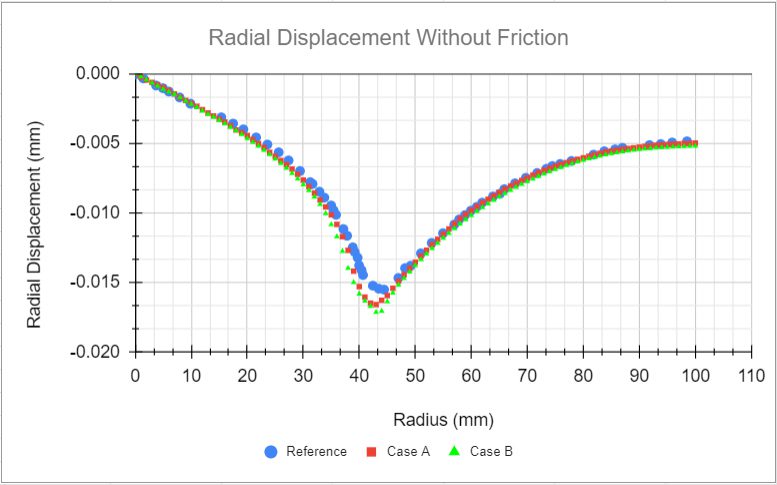

Now, still analyzing the results over the DE edge, we will compare the radial displacements obtained with SimScale to the reference ones.

Figure 6 shows contours for \(y\) displacement, in meters, for case D:

References

Last updated: September 30th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now