Documentation

This harmonic analysis of a straight beam validation case belongs to solid mechanics. It aims to validate the following parameter:

The harmonic analysis results from SimScale were compared to the analytical results from the formulation available in SHLL101

Find below the straight beam geometry used for this validation case:

The dimensions of the geometry are tabulated below. Furthermore, the center point C is located at the coordinates (0, 0, 0):

| Geometry Parameter | Dimension |

| Outer radius | 0.0925 |

| Inner radius | 0.08638 |

| Length | 10 |

Tool Type: Code_Aster

Analysis Type: Harmonic analysis

Mesh and Element Types: A total of four meshes are used in this validation case. The standard algorithm was used to create the meshes for cases A and B. The table below contains further information about the cases:

| Case | Mesh Type | Nodes | Element Type | Damping | Load Type |

| Case A1 | Standard | 83973 | 1st order tetrahedral | No | Tension |

| Case A2 | Standard | 83973 | 1st order tetrahedral | No | Bending |

| Case A3 | Standard | 83973 | 1st order tetrahedral | Rayleigh | Tension |

| Case A4 | Standard | 83973 | 1st order tetrahedral | Rayleigh | Bending |

| Case B1 | Standard | 503867 | 2nd order tetrahedral | No | Tension |

| Case B2 | Standard | 503867 | 2nd order tetrahedral | No | Bending |

| Case B3 | Standard | 503867 | 2nd order tetrahedral | Rayleigh | Tension |

| Case B4 | Standard | 503867 | 2nd order tetrahedral | Rayleigh | Bending |

Find below the tetrahedral mesh used for case A:

Material:

Boundary Conditions:

The analytical solution for the displacements, velocity, and acceleration on the point (10, 0, 0) are presented in SHLL101

Note

The point (10, 0, 0), where the reference results were calculated, is the center point of the annulus.

As this point is not within the solid walls of the pipe, a total of 4 points were created on the free end to assess the results:

The coordinates of the points are as follows:

– Left: (10, 0, 0.08944)

– Right: (10, 0, -0.08944)

– Top: (10, 0.08944, 0)

– Bottom: (10, -0.08944, 0)

SimScale results are the average of the values obtained at these four points. When tension is being applied, the results are evaluated in the x-direction. Otherwise, if a bending load is applied, the results are taken in the y-direction.

In Table 3, we compare SimScale results with the reference SHLL101

| Case | Displacement in x-direction [ | Error [%] | Velocity in x-direction [ | Error [%] | Acceleration in x-direction [ | Error [%] |

| SHLL101 (Real) | 5.3180E-05 | – | 0 | – | -2.0990E-01 | – |

| SHLL101 (Imaginary) | 0 | – | 3.3410E-03 | – | 0 | – |

| Case A1 (Real) | 5.3433E-05 | 0.4735 | 0 | 0 | -2.1095E-01 | 0.4973 |

| Case A1 (Imaginary) | 0 | 0 | 3.3580E-03 | 0.5060 | 0 | 0 |

| Case B1 (Real) | 5.3105E-05 | -0.1409 | 0 | 0 | -2.0965E-01 | -0.1188 |

| Case B1 (Imaginary) | 0 | 0 | 3.3367E-03 | -0.1292 | 0 | 0 |

Table 4 shows a similar comparison, but now for the cases with a bending load and no damping.

| Case | Displacement in y-direction [ | Error [%] | Velocity in y-direction [ | Error [%] | Acceleration in y-direction [ | Error [%] |

| SHLL101 (Real) | -2.1160E-02 | – | 0 | – | 8.3550E+01 | – |

| SHLL101 (Imaginary) | 0 | – | -1.3300E+00 | – | 0 | – |

| Case A2 (Real) | -2.1066E-02 | -0.4443 | 0 | 0 | 8.3167E+01 | -0.4606 |

| Case A2 (Imaginary) | 0 | 0 | -1.3236E+00 | -0.4805 | 0 | 0 |

| Case B2 (Real) | -2.1066E-02 | -0.4443 | 0 | 0 | 8.3167E+01 | -0.4606 |

| Case B2 (Imaginary) | 0 | 0 | -1.3237E+00 | -0.4797 | 0 | 0 |

Now, comparing the cases with tension load and the Rayleigh damping model:

| Case | Displacement in x-direction [ | Error [%] | Velocity in x-direction [ | Error [%] | Acceleration in x-direction [ | Error [%] |

| SHLL101 (Real) | 5.2960E-05 | – | 2.1130E-04 | – | -2.0910E-01 | – |

| SHLL101 (Imaginary) | -3.3630E-06 | – | 3.3270E-03 | – | 1.3270E-02 | – |

| Case A3 (Real) | 5.3219E-05 | 0.4859 | 2.1237E-04 | 0.5038 | -2.1010E-01 | 0.4764 |

| Case A3 (Imaginary) | -3.3800E-06 | 0.5021 | 3.3439E-03 | 0.5045 | 1.3344E-02 | 0.5516 |

| Case B3 (Real) | 5.3226E-05 | 0.4998 | 2.1262E-04 | 0.6208 | -2.1007E-01 | 0.4603 |

| Case B3 (Imaginary) | -3.3758E-06 | 0.3803 | 3.3433E-03 | 0.4881 | 1.3359E-02 | 0.6684 |

Lastly, the results for bending load and damping are compared in Table 6:

| Case | Displacement in y-direction [ | Error [%] | Velocity in y-direction [ | Error [%] | Acceleration in y-direction [ | Error [%] |

| SHLL101 (Real) | -2.1020E-02 | – | 1.1460E-01 | – | 8.2980E+01 | – |

| SHLL101 (Imaginary) | -1.8230E-03 | – | -1.3210E+00 | – | 7.1980E+00 | – |

| Case A4 (Real) | -2.0924E-02 | -0.4583 | 1.1325E-01 | -1.1903 | 8.2605E+01 | -0.4537 |

| Case A4 (Imaginary) | -1.8025E-03 | -1.1390 | -1.3147E+00 | -0.4784 | 7.1159E+00 | -1.1542 |

| Case B4 (Real) | -2.0924E-02 | -0.4583 | 1.1325E-01 | -1.1894 | 8.2605E+01 | -0.4537 |

| Case B4 (Imaginary) | -1.8025E-03 | -1.1390 | -1.3147E+00 | -0.4784 | 7.1159E+00 | -1.1542 |

SimScale results show great agreement with the analytical solution for all configurations.

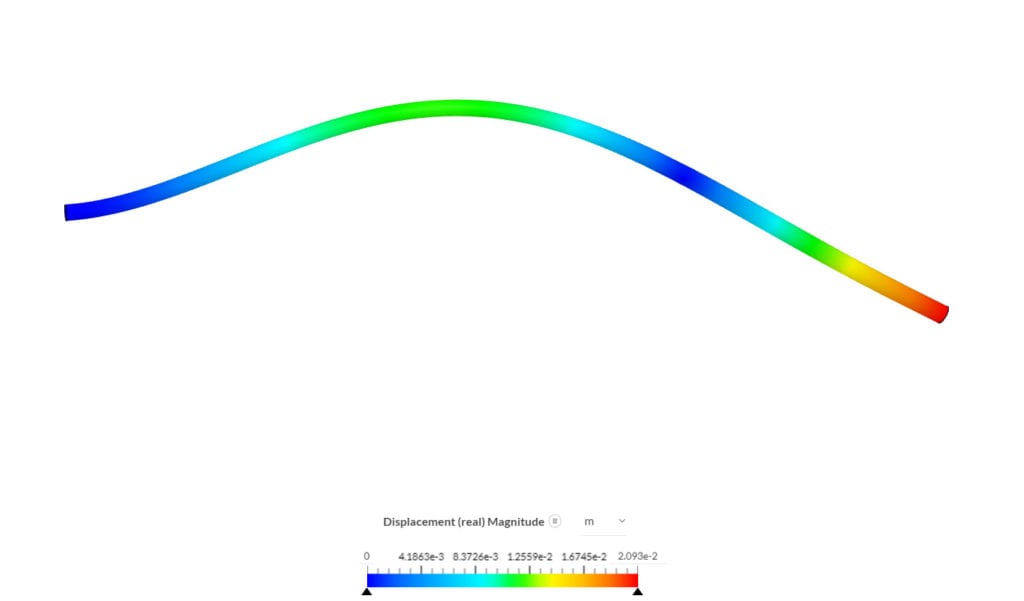

Inspecting the displacement magnitude for case B4 in the post-processor:

References

Last updated: June 14th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now