Documentation

In the ever-evolving landscape of engineering and design, finding the perfect balance between conflicting objectives is often a challenging task. Traditional optimization techniques might struggle to cope with the complexity of real-world problems that involve multiple conflicting goals. However, with the advent of Multi-Objective Optimization (MOO) and cloud-based simulation tools like SimScale, engineers and designers now have a powerful combination at their disposal to streamline the design process and achieve remarkable shape optimization results.

Multi-Objective Optimization (MOO) is an optimization technique used to optimize designs when multiple objectives are involved. In engineering scenarios, it is quite common to have more than one simultaneous objective, such as minimizing weight, maximizing performance, and reducing costs. Unlike single-objective optimization, which aims to find a single optimal solution, MOO aims to identify a set of solutions, known as the Pareto front.

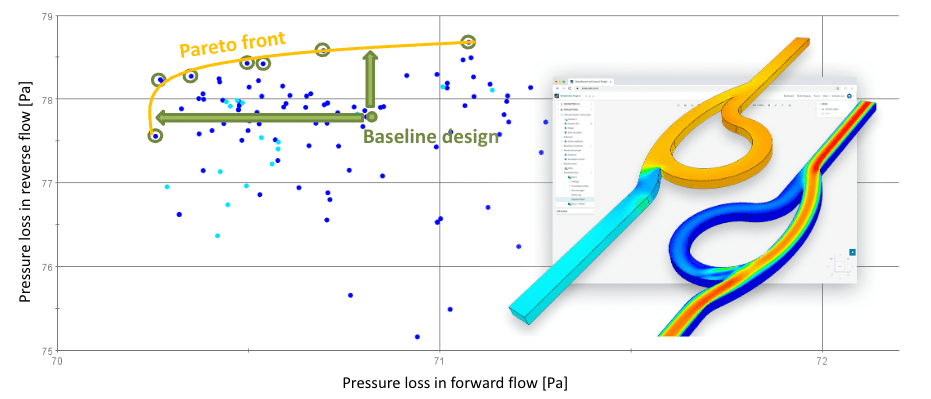

In Figure 1, the Pareto front is displayed for an optimization of a Tesla valve with Optimus, an Automation and Optimization tool by Noesis Solutions, and SimScale as the simulation tool.

Watch the on-demand webinar for this application here: Tesla Valve Design Optimization in SimScale.

The baseline design highlighted at the base of the arrows was improved upon for the pressure loss in both directions, and the plotted line shows the Pareto front with the non-dominated boundary points highlighted. The design cannot be improved beyond those points within the constraints used in the optimization.

Though the terms might sound similar, there is a notable distinction between multi-objective optimization and many-objective optimization. While both involve dealing with multiple objectives, multi-objective optimization describes scenarios with two or three objectives. On the other hand, many-objective optimization refers to scenarios where the number of objectives is relatively large, often in the range of four or more.

Handling many-objective optimization becomes significantly more complex due to the increased size of the Pareto front and the need for sophisticated visualization and decision-making techniques.

The Pareto front represents a unique concept in Multi-Objective Optimization, and knowing how to leverage the Pareto front is a crucial part of designing with Multi-Objective Optimization. The Pareto front is a collection of solutions where no improvement in one objective can be made without causing a deterioration in at least one other objective. In simpler terms, these solutions are considered non-dominated, as there is no single “best” solution but a range of compromises between objectives. Engineers and designers can then select the most suitable design from this Pareto front based on their specific requirements and preferences.

Pareto optimization lies at the core of MOO, as it seeks to explore and identify solutions on the Pareto front. This process involves using sophisticated algorithms to analyze a vast number of design alternatives, producing a diverse range of optimal solutions.

One of the key challenges in Pareto optimization is striking the right balance between the objectives, as enhancing one may negatively impact another. However, cloud-based simulation tools and optimization software have revolutionized this process, enabling engineers to efficiently compute the Pareto front and make informed decisions much more quickly and easily than ever before.

To achieve MOO efficiently, powerful optimization algorithms are employed. These algorithms intelligently navigate the vast design space, searching for solutions that closely approximate the Pareto front. Several state-of-the-art optimization algorithms are commonly used, including:

Shape optimization is a specific application of MOO that focuses on altering the shape of a design to achieve desired objectives. Whether it is optimizing the aerodynamics of an aircraft wing, reducing drag in a car’s body, or minimizing the pressure drop through a valve, shape optimization plays a crucial role in enhancing overall performance.

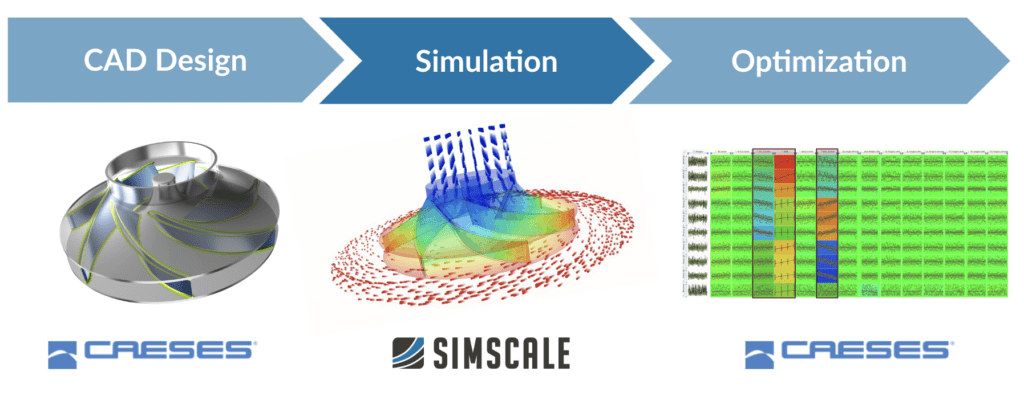

By leveraging cloud-based simulation tools like SimScale and automated shape optimization tools like Friendship Systems CAESES® and Optimus from Noesis Solutions, engineers can iterate through design variations rapidly and efficiently, leading to breakthroughs in product development.

There are some prerequisites for setting up a MOO, including:

Once the prerequisites are met, a MOO is typically conducted as follows:

An example of a workflow with CAESES and SimScale can be seen in Figures 3 and 4.

Comprehensive Decision-Making:

MOO provides engineers with a holistic view of the design space, revealing the trade-offs between different objectives. This empowers them to make informed decisions that align with project goals, customer requirements, and budget constraints.

Time and Cost Efficiency:

Cloud-based simulation tools, combined with MOO algorithms, significantly reduce the time and resources required for design iterations. Engineers can explore a vast range of design alternatives in parallel, leading to quicker convergence on optimal solutions.

Innovation and Creativity:

By unlocking the potential of the Pareto front, MOO encourages innovative thinking and creativity. Engineers can explore unconventional design ideas and push the boundaries of what’s possible to discover breakthrough solutions.

Scalability and Flexibility:

SimScale offers unparalleled scalability, allowing engineers to access vast computational resources on demand. This means simulations can be run in parallel, significantly reducing the time required for optimization tasks and enabling the exploration of more design alternatives.

Cost-Effectiveness:

Traditional on-premises simulation setups can be expensive to maintain and upgrade. SimScale eliminates the need for expensive hardware investments, allowing companies to pay only for the computing resources they use.

Collaboration and Accessibility:

SimScale promotes collaboration among team members regardless of their physical location. Designers, engineers, and stakeholders can access simulation data and optimization results from anywhere with an internet connection, streamlining the communication and decision-making processes.

Automated Workflows and API capability:

SimScale’s API connections mean that the whole process can be automated, enabling engineers to set up complex simulations and optimization workflows with ease. This automation reduces manual intervention, minimizes errors, and accelerates the entire design process.

Integration with Design Software:

SimScale integrates seamlessly with popular Computer-Aided Design (CAD) and optimization software. This allows engineers to easily transfer and modify design geometries for simulations, saving time and effort during the optimization process.

As the field of engineering continues to evolve, the importance of Multi-Objective Optimization and shape optimization cannot be overstated. These cutting-edge techniques, powered by advanced optimization algorithms like Friendship Systems CAESES and Optimus from Noesis Solutions, along with cloud-based simulation tools like SimScale, empower engineers and designers to achieve optimal designs, striking the perfect balance between conflicting objectives. Embracing these methodologies opens new possibilities, driving innovation and efficiency in product development while meeting the diverse needs of consumers in a rapidly changing world.

By leveraging the concepts of the Pareto front, Pareto optimization, optimization algorithms, and shape optimization, engineers can navigate the intricate trade-offs between competing objectives efficiently. These methodologies empower innovation, creativity, and robust decision-making, leading to groundbreaking designs.

Last updated: August 25th, 2023

We appreciate and value your feedback.

What's Next

Pre-processingSign up for SimScale

and start simulating now