Documentation

This validation case belongs to solid mechanics. The aim of this test case is to validate the following parameters on a fixed beam, that is subjected to a temperature change of 10

The simulation results of SimScale were compared to the results presented in [Roark]

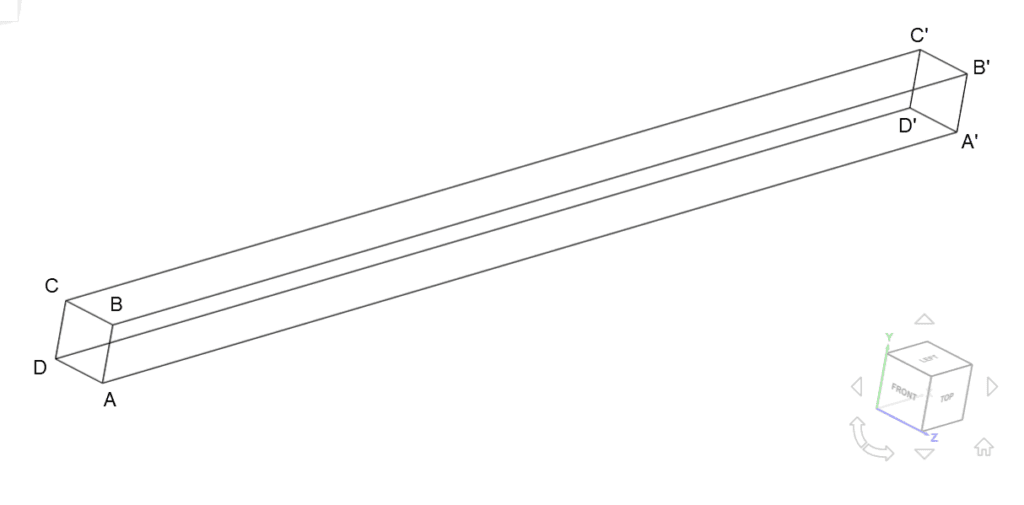

A bar with a square cross-section was used for this case:

The cross section area of the bar is

Tool Type: Code_Aster

Analysis Type: Thermomechanical, linear with static inertia effect

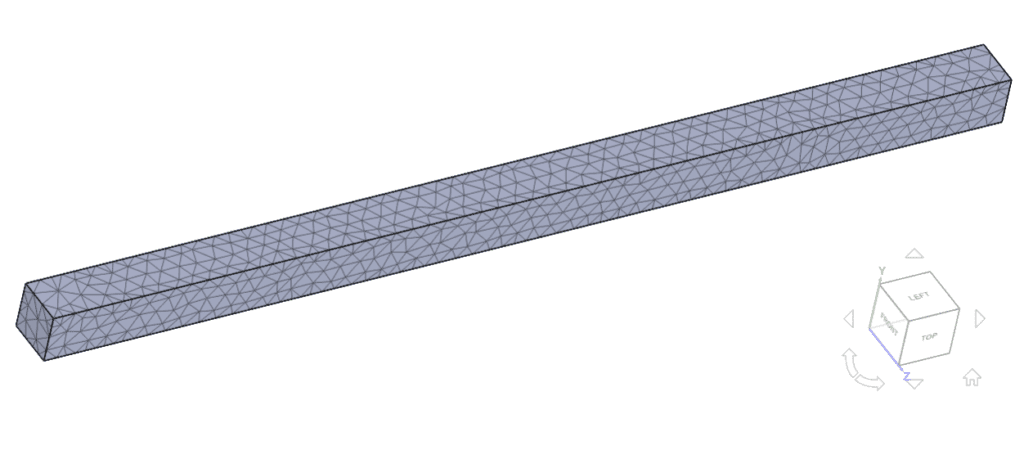

Mesh and Element Types:

The meshes used in (A) and (B) were created with the Standard mesher tool on the SimScale platform. Details can be found in Table 1:

| Case | Mesh type | Number of nodes | Element type |

| A | Standard | 1484 | 1st order tetrahedral |

| B | Standard | 9320 | 2nd order tetrahedral |

Material:

Boundary Conditions:

The analytical solution for the unit stress is given by the following equation:

where:

As a result, the analytical calculation gives a unit stress of:

Comparison of the unit stress

| Case | [Roark] | SimScale | Error |

| A | 24.6 | 24.6 | 0.00 |

| B | 24.6 | 24.6 | 0.00 |

As shown in Table 2, the SimScale results perfectly match the analytical ones with 0.00% error.

Last updated: July 21st, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now