Documentation

This design analysis of a spherical pressure vessel validation case belongs to thermomechanics. This test case aims to validate the following parameters:

The simulation results of SimScale were compared to the analytical results presented in [Afkar]

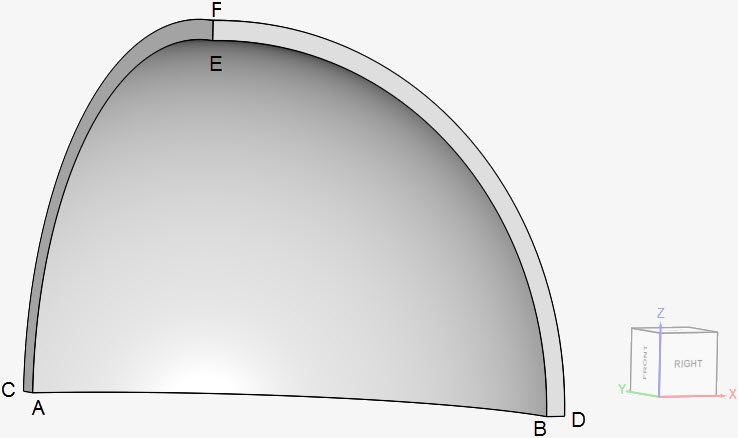

The geometry consists of 1/8th of a sphere, with an inner radius of 0.19

The coordinates for the points in the sphere are as tabulated below:

| A | B | C | D | E | F | |

| x | 0 | 0.19 | 0 | 0.2 | 0 | 0 |

| y | 0.19 | 0 | 0.2 | 0 | 0 | 0 |

| z | 0 | 0 | 0 | 0 | 0.19 | 0.2 |

Tool Type: Code_Aster

Analysis Type: Transient thermomechanical, linear

Mesh and Element Types: The mesh for cases A and B was created with the standard algorithm, with first order elements.

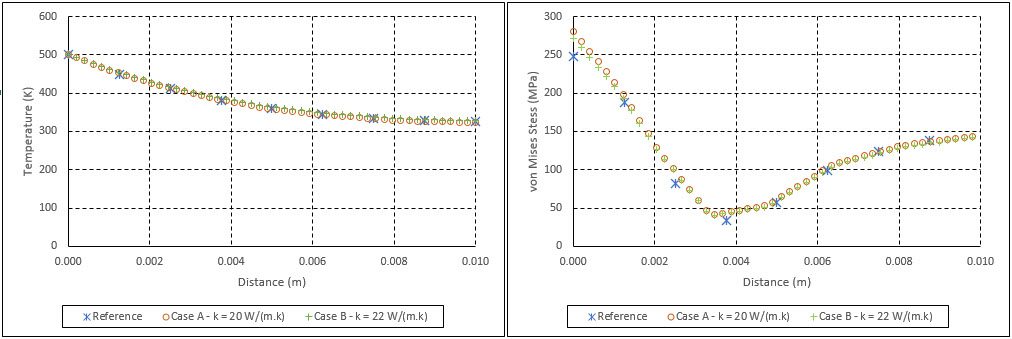

The setup from cases A and B is the same, except for the thermal conductivity

| Case | Mesh Type | Nodes | Thermal Conductivity | Element Type |

| (A) | 1st order standard | 172833 | 20 | Standard |

| (B) | 1st order standard | 172833 | 22 | Standard |

Find below the mesh used for both cases. It’s a standard mesh with first order tetrahedral cells.

Material:

Initial Conditions

Temperature is 300

Boundary Conditions:

The analytical solution is given by the equations presented in [Afkar]

Since no value for thermal conductivity

In Figure 4, we can see how temperature is changing in the sphere’s width, for the last time step:

Last updated: November 7th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now