ON-DEMAND WEBINAR

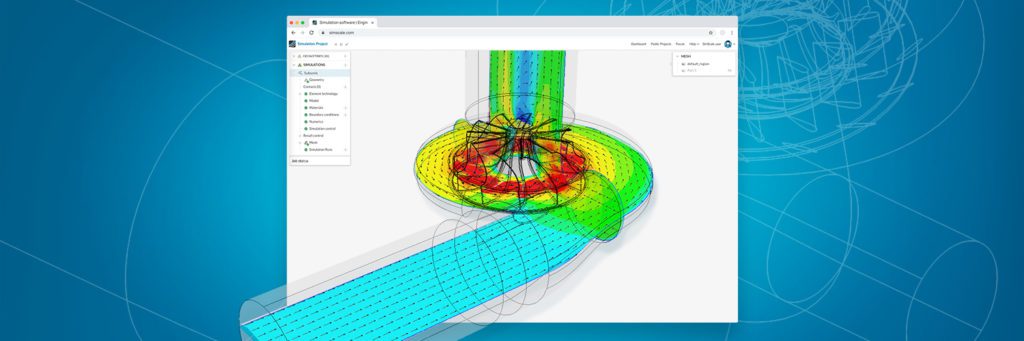

Pump Performance - Analysis of Cavitation Effects with Engineering Simulation in the Cloud

One of the leading causes of performance deterioration of pumps and hydraulic turbines is cavitation, which refers to the formation of vapor bubbles inside the working liquid. Cavitation manifests itself in the form of vibrations, noise, and a drop in pump efficiency, and if left unchecked, it can lead to total equipment failure.

Watch this webinar to learn how you can use the cavitation modeling capability available in SimScale to understand its effect on the performance of a real-life pump. A thorough characterization of the cavitation phenomenon, along with an understanding of the design factors that lead to cavitation, is possible thanks to the practically unlimited computational power of engineering simulation in the cloud.

Our experts demonstrate the step-by-step process of setting up a cavitation simulation in SimScale, including how to recognize cavitating flow and the effect of important design factors influencing the onset of cavitation, such as NPSHR, cavitation number, and inlet sizing.

Senior Application Engineer

With a background in Aeronautical/ Aerospace Engineering and a Master’s degree in Computational Engineering from Ruhr University Bochum, Ajit is a part of SimScale’s Application Engineering Team.

“SimScale drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage) and simulation accuracy. It allows us to complete development cycles within days instead of months which gives us a massive advantage over our competition. I would say that this software is not evolutionary but rather disruptive. My recommendation to use SimScale for anyone in the engineering design space cannot be higher.”

“SimScale is an amazing platform that enables CAE to be carried out with minimal fuss and resources. Being cloud-based, it opens us access to anyone with an Internet connection and gives the ability to select the number of cores to be used, therefore there is no physical computing power resource requirement for the user.”

SimScale is the world’s first cloud-native SaaS engineering simulation platform, giving engineers and designers immediate access to digital prototyping early in the design stage, throughout the entire R&D cycle, and across the entire enterprise. By providing instant access to a single fluid, thermal, and structural simulation tool built on the latest cloud computing technology, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly web application, accessible to any designer and engineer in the world.

Sign up for SimScale

and start simulating now