High efficiency is an important criterion in the fan design process, as fans consume 18% of electricity in commercial and industrial buildings and processes. With standards such as ASHRAE 90.1-2013 and Commission Regulation (EU) No 327/2011, there are requirements for fan efficiency based on metrics like FEG, FMEG, and FEI. These standards greatly impact fan design conditions and thus their selection by customers. To meet efficiency goals, the classical approach to Design – Build – Test – Redesign is time-consuming and expensive. Commercial and industrial fans designers are now turning to an effective method to virtually test, make an accurate aerodynamic assessment, and optimize using engineering simulation. Computational Fluid Dynamics (CFD) is the method that is used for the computerized calculation of fan aerodynamic quality to accurately predict fan performance earlier in the design stage, analyze various designs, reduce the number of physical prototypes and expensive testing, optimize designs for maximum performance, shorten the design cycle and minimize costs.

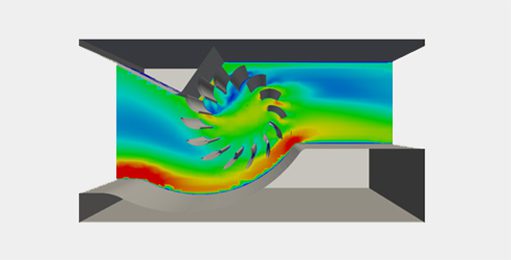

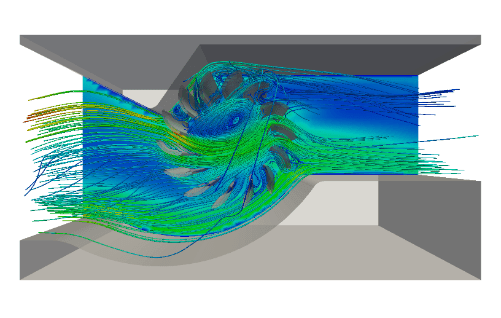

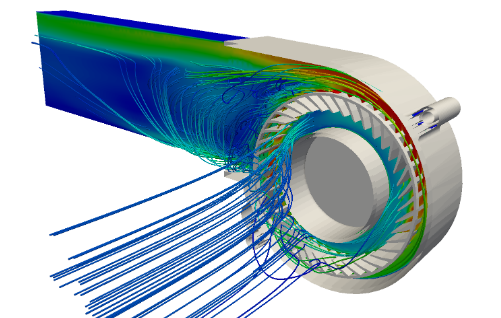

CFD enables you to predict the 3D flow field distribution for your fan design and determine the output velocities and flow rates for different operating conditions.

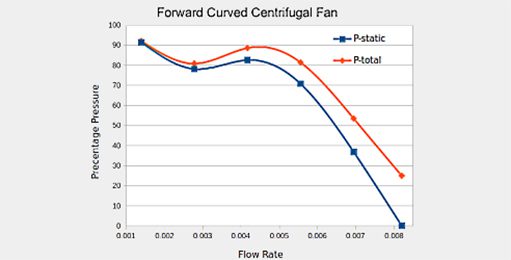

Analyze existing designs to determine the static and total pressure rise of the fan. Optimize current fan and blade designs to improve their performance.

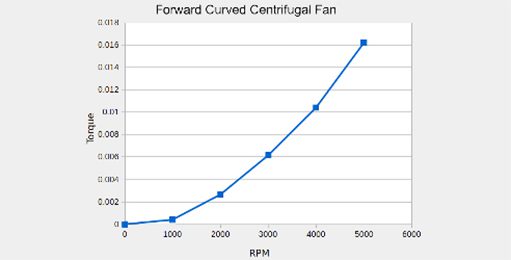

Calculate the aerodynamic forces and moments acting on the rotor to determine the torque for various flow rates and RPMs.

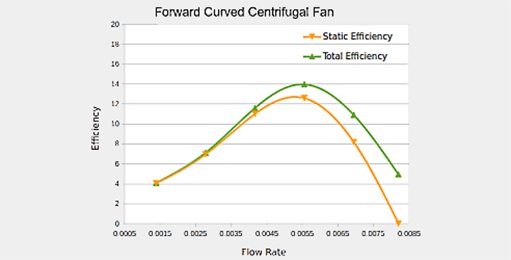

Evaluate the static and total fan efficiency for an existing design at different flow rates to determine the peak operating condition. Analyze the designs and based on the results, make improvements in increasing efficiency and costs saving. With this white paper, discover how to use CFD to improve energy efficiency of fans for air handling units.

Investigate fan designs and determine their performance in terms of static and total pressure rise for a range of operating flow rates. The performance curves obtained are key indicators for deciding whether the design meets the requirements or needs optimization. Watch this webinar to learn how to optimize a fan design using online CFD.

Determine the net torque on the rotor due to aerodynamic forces for a range of operating revolutions per minute (RPMs).

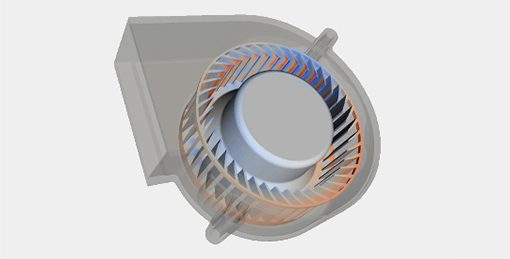

Producing an even laminar airflow and allowing horizontal or vertical mounting, a cross flow fan prevents the overheating of electronic components. Early in the design process, fans can be virtually tested with CFD to make sure the highest efficiency and performance and the lowest noise are achieved. A simulation software can also help in performing vibration analyses and predicting the aerodynamics of the fan, everything long before creating a physical prototype.

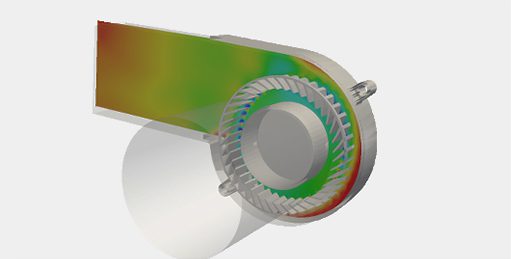

When selecting fans for HVAC applications, many engineers choose centrifugal fans for their energy efficiency, durability, and ease of maintenance. SimScale’s CFD solution allows designers of centrifugal fans to accurately calculate flow rates, static pressure, total pressure, static efficiency, total efficiency, peak total efficiency, forces and moments acting on the fans, and more.

Fans need to fulfill very strict governmental regulations which is why it is crucial that they are designed to be as effective as possible. Bringing the design faster to the market is also important to stay ahead of the competition. You can achieve this with the simulation techniques you learn here!

I loved the fact that I could do what I need to do in a browser. I started working without installing any software. Using any computer I could upload the model and start the analysis. That was the big “wow” moment.

Ben Lewis President at Custom Machines

Sign up for SimScale

and start simulating now