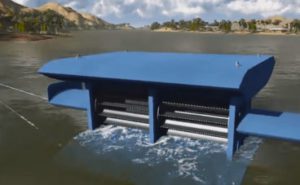

Founded in 2002 in Orkney, Orbital Marine Power Limited develops cost-effective floating tidal stream turbines. Over the years, the company continued to expand by gradually improving their core product, acquiring business and technology partners, and obtaining significant EU grants. With over 17 engineers and technicians onboard, Orbital Marine Power is unquestionably one of the world’s leaders in the tidal energy transformation industry.

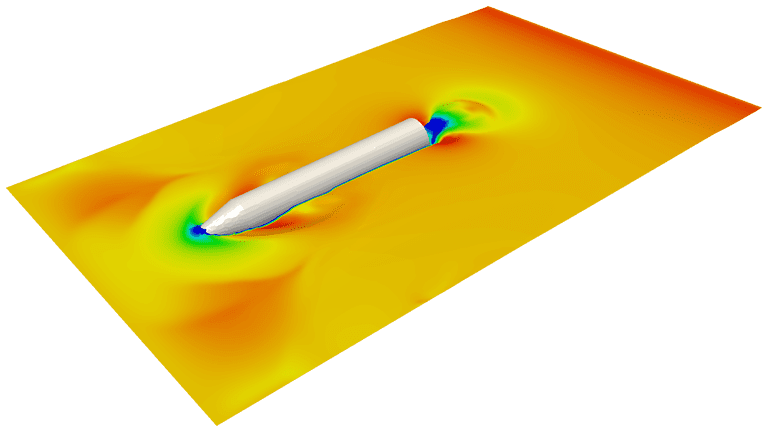

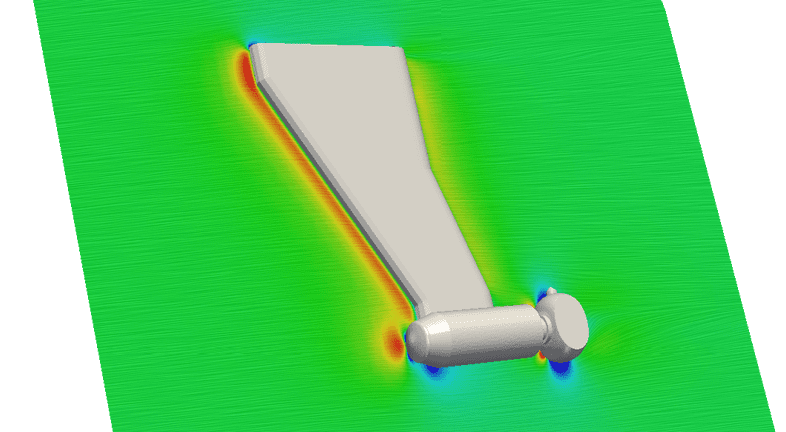

The incorporation of computer-aided engineering (CAE) at Orbital Marine Power was driven by two main reasons. The first one was to model the turbine leg and nacelle to optimise the hydrodynamic performance and reduce the impact of the shadow effect. This would result in an increased performance of the turbine. With this in mind, simulations were carried out to better quantify the drag and lift coefficients.

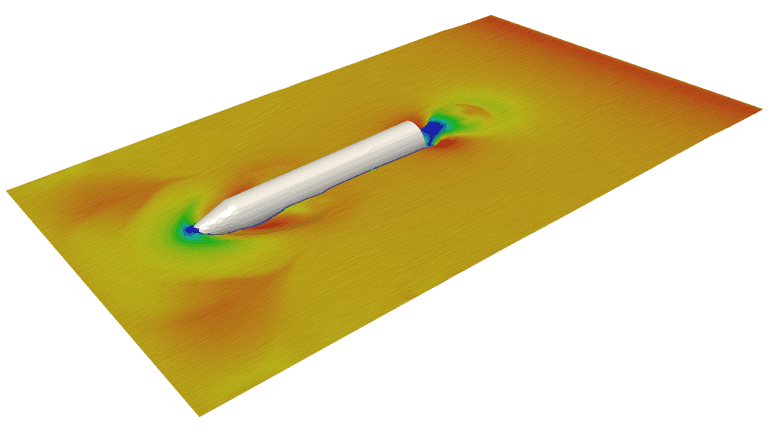

The second main area of interest included carrying out multiphase simulations of the turbine, the leg and nacelle in the up (maintenance) position. The aim was to help visualise how the tide flow will interact with the turbine so that the maintenance access can be examined. This is of particular importance at the nose of the turbine, where the towing point is situated.

Although it is designed for minimal manual intervention, it still needs to be accessible for safety reasons. Alongside the nose of the turbine, further critical points of modeling were at the nacelle and leg. These are to be accessed on site, with potentially strong tidal conditions. The nacelle and leg have two important entry points: one on the hub for accessing the variable pitch system and one on the nacelle body. It is critical that both areas are easy to access in the event of any failures.

Prior to using SimScale, the Orbital Marine Power team simulated with other CFD packages, but they had high subscription costs and were considerably more limiting in availability of use in their two different offices. Being cloud-based, SimScale enabled the engineers located at the Orkney office to collaborate on the projects with their collagues in Edinburgh. This is important due to the nature of the company’s business, where the engineers are required to spend a lot of their time at construction and production sites.

SimScale can be easily accessed from wherever an Internet connection is available, which was a great benefit to the team. With the platform, cumbersome remote desktop connections that were previously needed to access desktop-based software were completely avoided, providing a quick, reliable, and easy-to-use interface instead.

SimScale is an amazing platform that enables CAE to be carried out with minimal fuss and resources. Being cloud-based, it opens us access to anyone with an Internet connection and gives the ability to select the amount of cores to be used, therefore there is no physical computing power resource requirement for the user.

Mark Byers

Hydrodynamics Engineer at Orbital Marine Power

The main reason for Orbital Marine Power to be using SimScale was that, being cloud-based, it made it easy to run simulations and share results with other engineers. Since calculations were carried out in the cloud, the computer resources within the company were not put under any additional strain. This also led to the simulations being run quicker—engineers could specify how much CPU to use on the analyses.

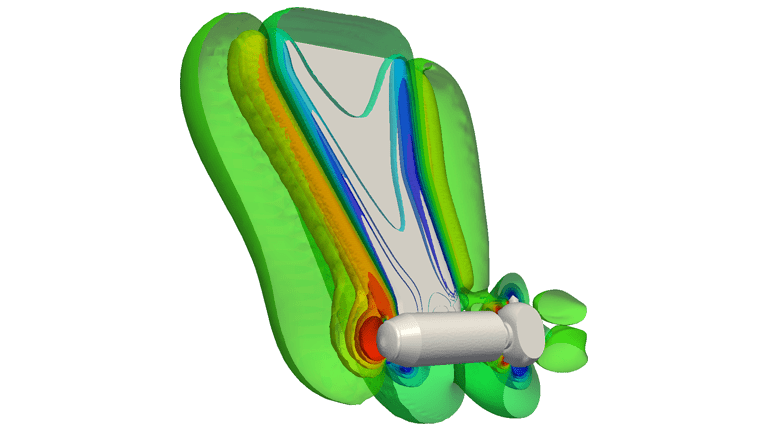

The focus was carrying out multiphase simulations, which allowed Orbital Marine Power to investigate the free surface surrounding both the turbine and the nacelle and hub geometries.

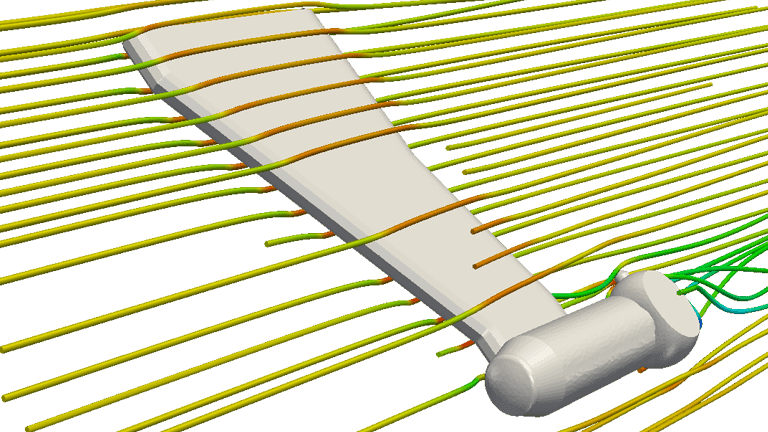

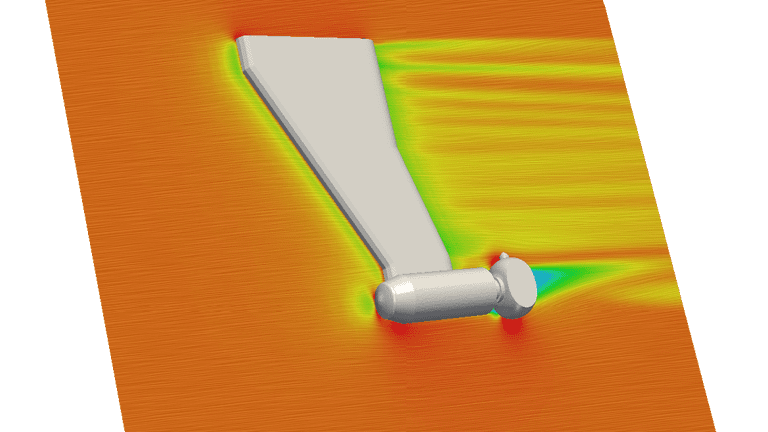

For investigating the flow around the leg to better quantify the CD (drag) and CL (lift) coefficients, the geometry was prepared for simulating wind tunnel conditions. An additional thin slice was added to the leg geometry to better understand the velocity deficit caused by the presence of the leg.

Predominantly hex-dominant parametric meshes were used of approximately 1-3 mln control volumes. A couple of instances used hex-dominant parametric wind tunnel for external flow.

In the beginning, the setup for the multiphase simulation has proven to be particularly challenging. Fortunately, SimScale’s online support staff helped address all the issues with it

“SimScale’s customer support and online help is second to none. Especially the chat option made it very easy to contact support, and the ability to share the project meant that we could download a copy and work through to find a solution. The process was very quick and it proved to be incomparably better to any support that our team has come across. It really is an outstanding platform,” said Mark Byers, Hydrodynamic Engineer at Orbital Marine Power.

All performed simulations ran well and all reached at least 1e-4 in residual within the maximum prescribed runtime. For the leg performance, a number of simulations were run to ensure repeatability. Simulations were carried out at various inflow speeds to validate the aerodynamic performance of the leg. In addition, several simulations were run for the investigation of the wake patterns.

The results obtained allowed the team to confirm the CD and CL of the leg, plot streamlines and track velocity deficit. This helped to feed directly into the design of the legs and to optimise the turbine’s performance.

Computer-aided engineering has proven to be a great tool in the design process of Orbital Marine Power, enabling small changes to be investigated and optimized. Without CAE, various scale model tests would have needed to be undertaken, which would have been costly and very time-consuming. With each new iteration of design, further tank tests would have been needed until the final design was reached. CAE with SimScale allowed Orbital Marine Power to reach the final design within a much quicker timeframe and saving considerable costs. It is planned that the final design will eventually be subjected to tank tests to validate the findings and ensure all design goals are met.

With the modeling done online, the Orbital Marine Power team saved several months as the design, manufacturing and testing iterations could be reduced. Coupled with this was the monetary saving, as the manufacture of scale models and testing can be costly ($3,000/day for tank hire).

In addition, the results provides by SimScale were directly used in the planning of marine operations and servicing of the nacelle and hub once the turbine will be in operation. It will allow for a decision to be made on suitable environmental conditions at which access can be attempted.

“To get the results from a scale model testing program would have taken 1-2 months and cost £10k for each iteration of the design. With SimScale, we were able to run simulations in just under an hour and make small design changes and run again, this condensed the iterative design process down to several days,” said Jonathan Meason, CTO at Orbital Marine Power.

By not having to do live scale testing of new concepts, Orbital Marine Power saved over £10,000. The design process was also shortened by at least 2-3 months. The use of the SimScale platform is already planned for and will take a significant part of the company’s latest turbine design.

With the product getting close to full commercialization, the simulations done on SimScale play a great role in impacting the tidal energy industry.

“SimScale is an incredible platform. It really increases the access to CAE for users of all abilities. It has the potentially to totally change the industry and has the capabilities of reaching considerably more users. The interface is incredibly easy to follow and allows to quickly gain a high level of competence. Finally the support either through expert chat or forums really makes the complete tool an incredibly enjoyable experience,” said Mark.

Sign up for SimScale

and start simulating now