Sandro Pinent, managing partner at Schübeler Technologies, is in charge of numerical calculations (CFD and FEA) and project management. Although he and his team were getting reasonable results from conventional data analysis, they decided to go one step further with numerical analysis. For finite element analysis, his team first relied on Code_Aster, but putting effort into the understanding of this complex program was a bottleneck and shouted for alternatives. Knowing the advantages of the solver itself, Sandro was looking for an easier way to use it.

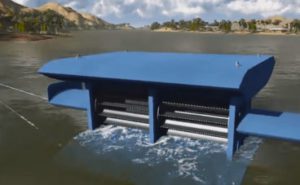

Although paper calculations gave a promising efficiency and the physical test also showed good results, it was still important to better understand the behavior of water through the turbine—how the pressure is distributed on the turbine blades for example. The project then moved to a critical stage, where modifications and improvements to the design had to be implemented in the technical drawings for the construction of the final turbine version.

He came across the SimScale platform by reading one of the company’s newsletters and decided to test it. Soon Sandro realized that SimScale made Code_Aster accessible to every engineer in the team. The original code is very hard to handle, let alone reading all the documentations in French. With the help of SimScale’s user interface, Sandro and his colleagues at Schübeler Technologies were able to easily set up a simulation and work efficiently.

The main advantage to use SimScale for us is to have a fast and simple way to get FEM calculation results. We don’t really need experience with Code_Aster but still get really quick and reliable results. Also, the subscription price is reasonable.

Sandro Pinent

Managing Partner Schübeler Technologies

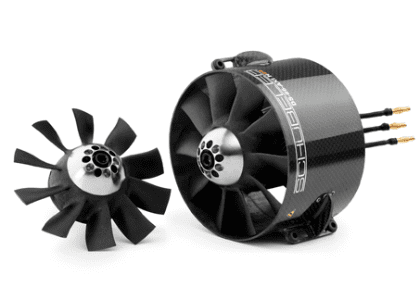

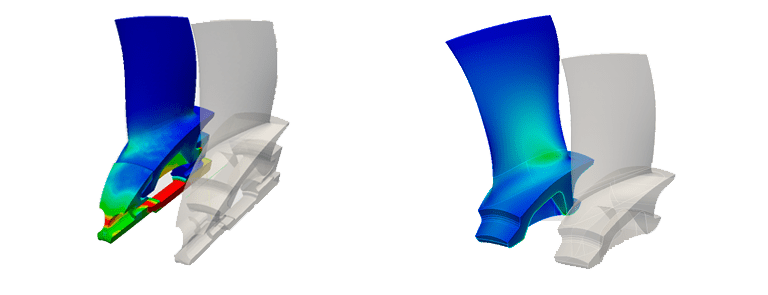

The first project performed on the SimScale platform was an analysis of the stress acting on a turbomachinery blade. The goal was to prove that the blades and mounting could withstand the operating conditions and that the design decisions taken in order to reduce the weight of the elements would not hinder the safety of the equipment.

With a step-by-step approach, only the blade was simulated at the beginning. Using a static, linear analysis our customer investigated the stress response of the blade up to a high rotation speed. Having obtained satisfactory results, Sandro was able to begin the investigation of the blade assembly. This stage required using a nonlinear static analysis with physical contacts. The simulations measured the stress response and the system’s deformation in working conditions of 50,000 rpm. In order to ensure a quick analysis workflow, the first simulation was performed using a coarse mesh. After proving that the setup was correct, a full-scale analysis on a refined mesh was done.

The nonlinear simulation of the blade assembly on the coarse mesh of 20,000 nodes took 24 minutes to run on a 4-core machine. A refined full study was done using 95,000 nodes and took 21 minutes on 32 cores.

This clearly shows the advantage of having easy access to supercomputer resources. The results obtained with the simulations have proven that the weight-optimized design is safe and can operate properly under working conditions.

Using the CAE approach, Sandro and his team saved time and money by reducing the number of physical prototypes of the fan that needed to be built and tested.

Sign up for SimScale

and start simulating now