Test, validate, and iterate designs more easily than ever before in a cloud-based platform

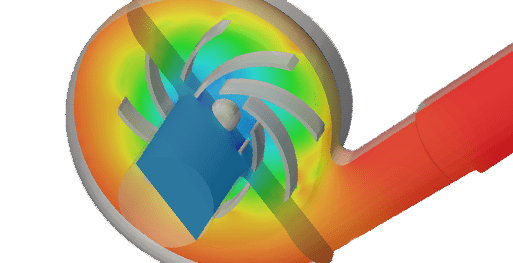

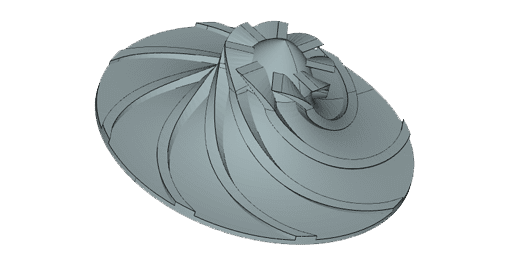

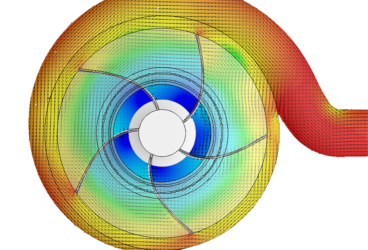

A pump impeller, or simply an impeller, is a rotating component of a pump device. This rotor transfers energy from the motor that moves and accelerates the fluid outwards from the center of rotation..

Pump impellers can be applied in a variety of scenarios, and exist as 3 main types that are then used in turbomachinery systems:

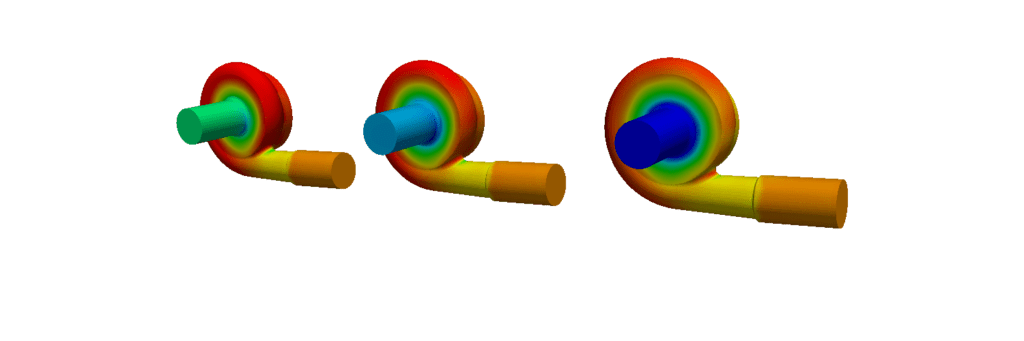

A pump impeller needs to be simulated and evaluated early in the design process to determine the optimal design. However, the high cost of hardware and steep learning curves of traditional, on-premises tools leave many designers to feel that simulation is not an option.

SimScale has eliminated such barriers , thanks to the power of the cloud. With SimScale, engineers can:

“At Quantex, the SimScale platform gives us access to powerful tools, in an economic package. The support is outstanding and helps add the most value to our engineering capabilities.”

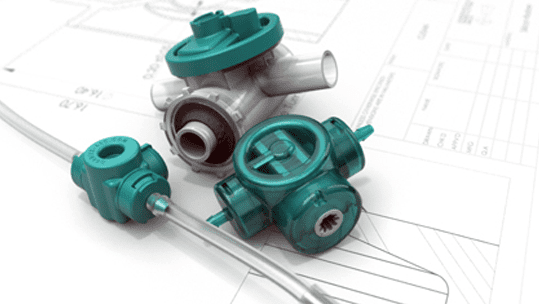

Your hub for everything you need to know about

valves and the world of simulation

Sign up for SimScale

and start simulating now