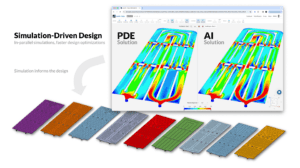

Foresee future circumstances, discover omissions in designs and apply corrections. The SimScale cloud-based simulation platform can be used to test and optimize designs in the construction and architecture industry including buildings, tunnels, roads, railways, canals, dams, flood and bridges.

Aerospace & defense companies can design next-generation aircraft and parts, optimize safety and comfort of commercial planes, improve fuel efficiency and decrease the negative impact on the environment. Everything with the SimScale cloud-based simulation software.

The largest automobile manufacturers in the world have adopted CAE as a compulsory step in their product development process. With SimScale, you can simulate automobiles, motorcycles, buses, trains, trucks, helicopters, watercraft, spacecraft, or any other vehicle.

SimScale supports the simulation of consumer products and parts, as diverse as mobile phones, beverage containers, car seats, racing bikes, and many more, with plenty of different simulation types, including solid mechanics, fluid dynamics and thermodynamics.

From electronic chips and printed circuit boards (PCBs) to smartphones or computers, SimScale is the perfect tool for electronics simulation, enabling companies to ensure power optimization, durability, efficiency or thermal performance for their products.

Enabling energy producers and transportation firms to simulate devices, tools, machinery or storage tanks, computer simulation is playing an important role in testing designs, making repeated changes and increasing overall efficiency in the energy industry.

Regardless of the industries they are specialized in, engineering offices from all over the world are using the SimScale simulation platform to virtually test their design via a standard Web browser and deliver the best quality to their customers in less time.

With SimScale, the innovation within the healthcare industry can be combined with improved design reliability and more affordable development process. The platform enables simulation of arteries or bones, medical and orthopedic equipment.

Perfectly suited for simulating all types of machinery and industrial equipment — with mounting, clamping, adjusting, rotating and other elements, SimScale is used for testing in construction, mining, automotive, chemical, steel and metal.

Optimized for a wide range of machines, tools and processes, the SimScale cloud-based simulation platform is being intensively used in manufacturing, for industry-specific applications.

Being an integral part of the design process, from concept to product release and certifications, CFD simulation is an indispensable tool in the marine industry.

Your hub for everything you need to know about simulation and the world of CAE

Sign up for SimScale

and start simulating now