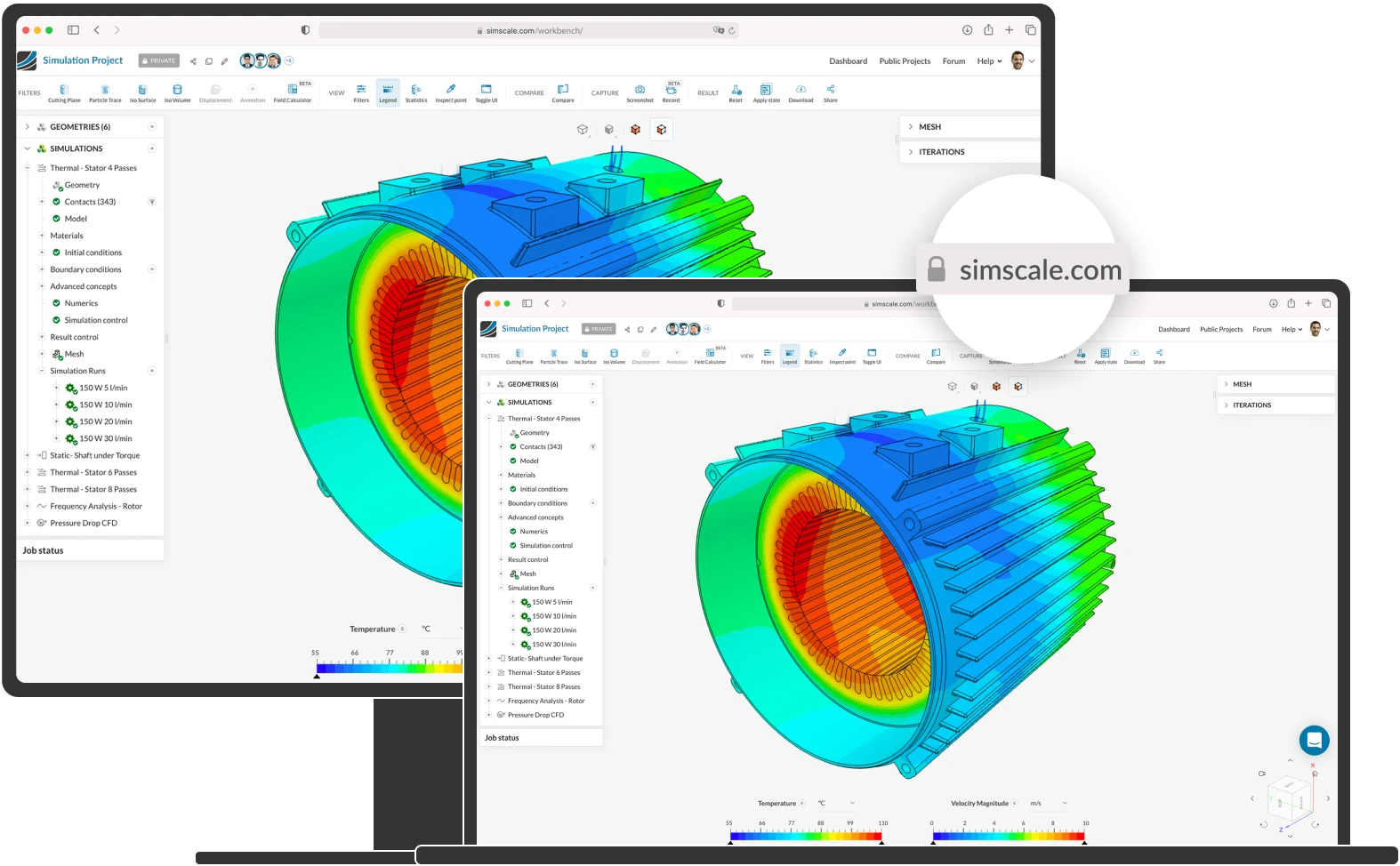

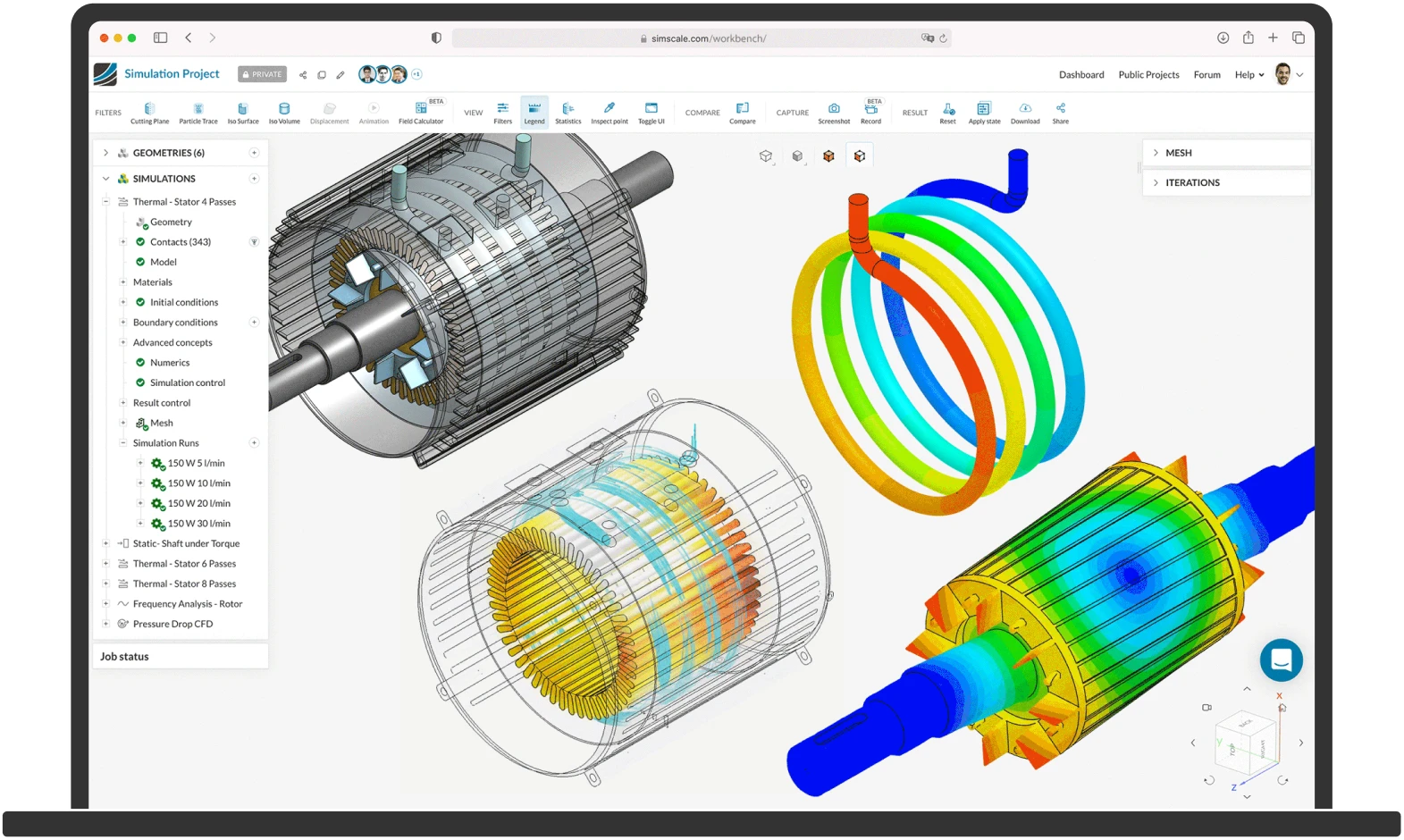

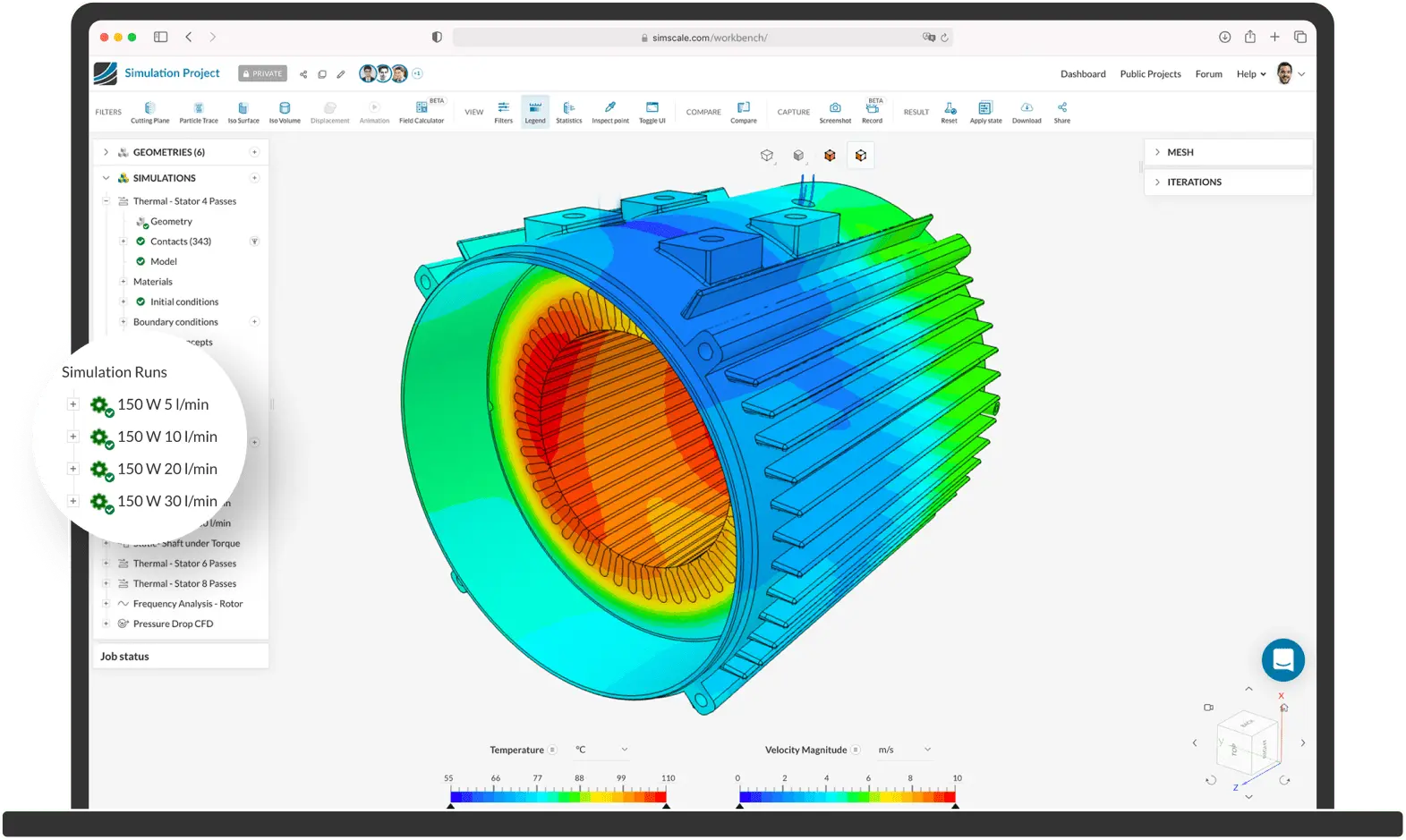

SimScale empowers engineers with: fluid dynamics, structural mechanics, thermodynamics, electromagnetics and multiphysics analysis in the cloud.

Trusted by 500,000+ users

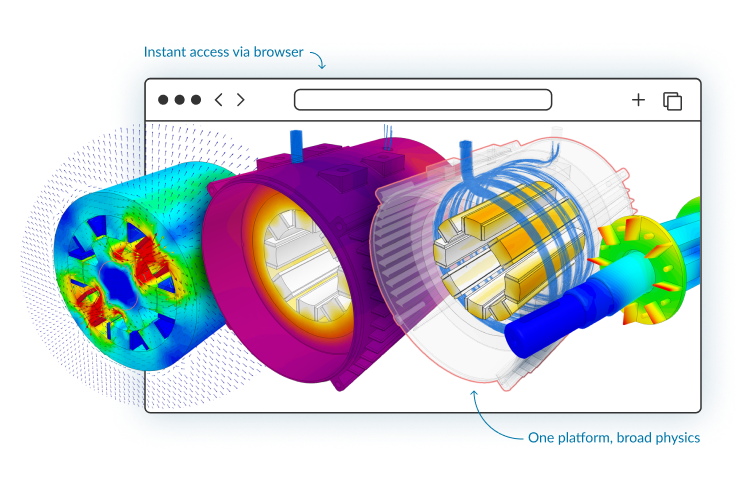

No VPN, No remote desktop. True SaaS with instant access anywhere & anytime from a browser without any special hardware.

No disconnected tools used in silos. A single platform with broad physics capabilities for both rough early- and detailed late-stage simulations.

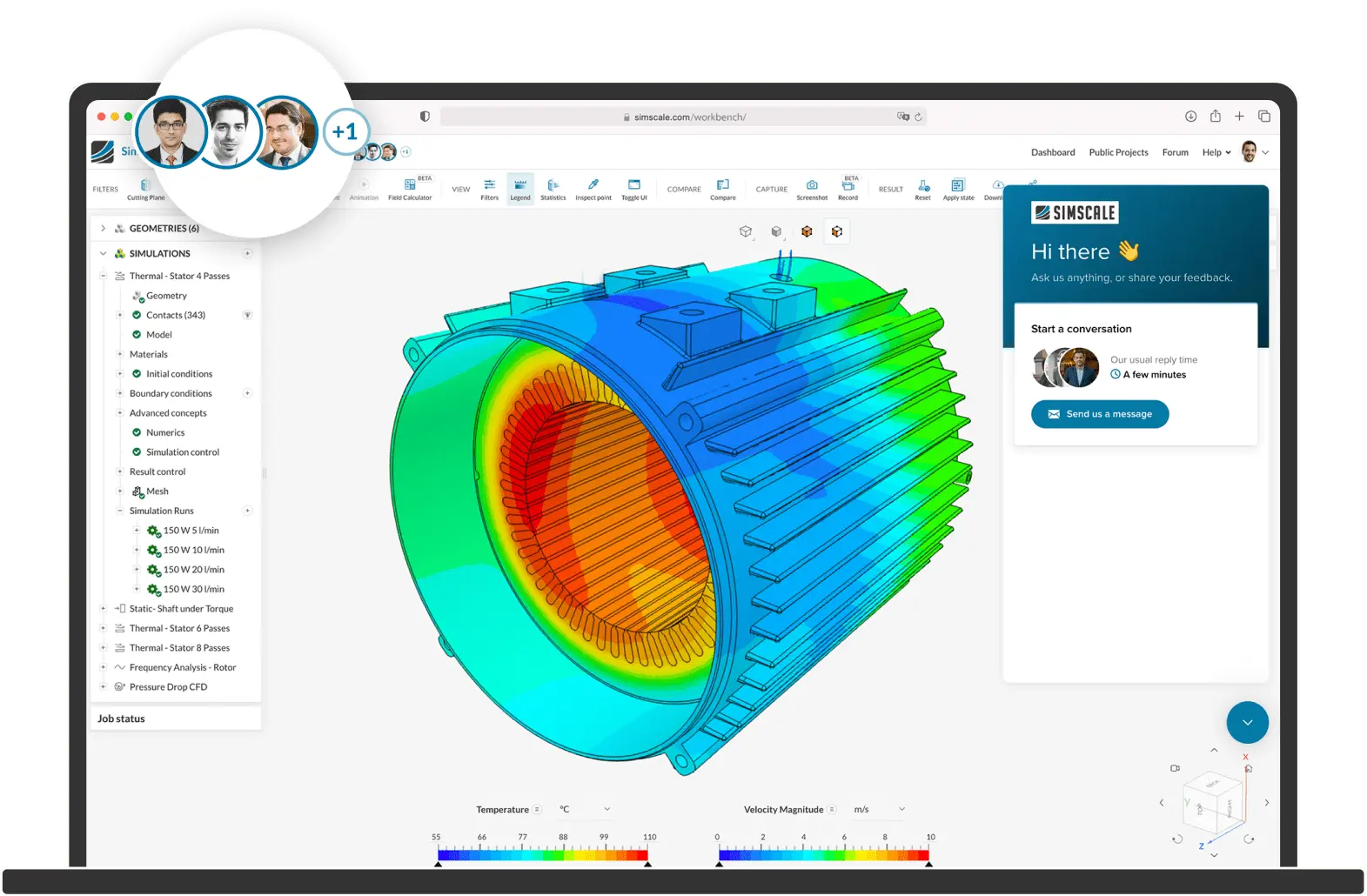

Google-Docs-style collaboration built-in, enabling unparalleled in-app support as well as sharing simulations with colleagues.

Practically no limits to simulation size, number of parallel simulations and storage. From one-off runs to programmatic design space exploration.

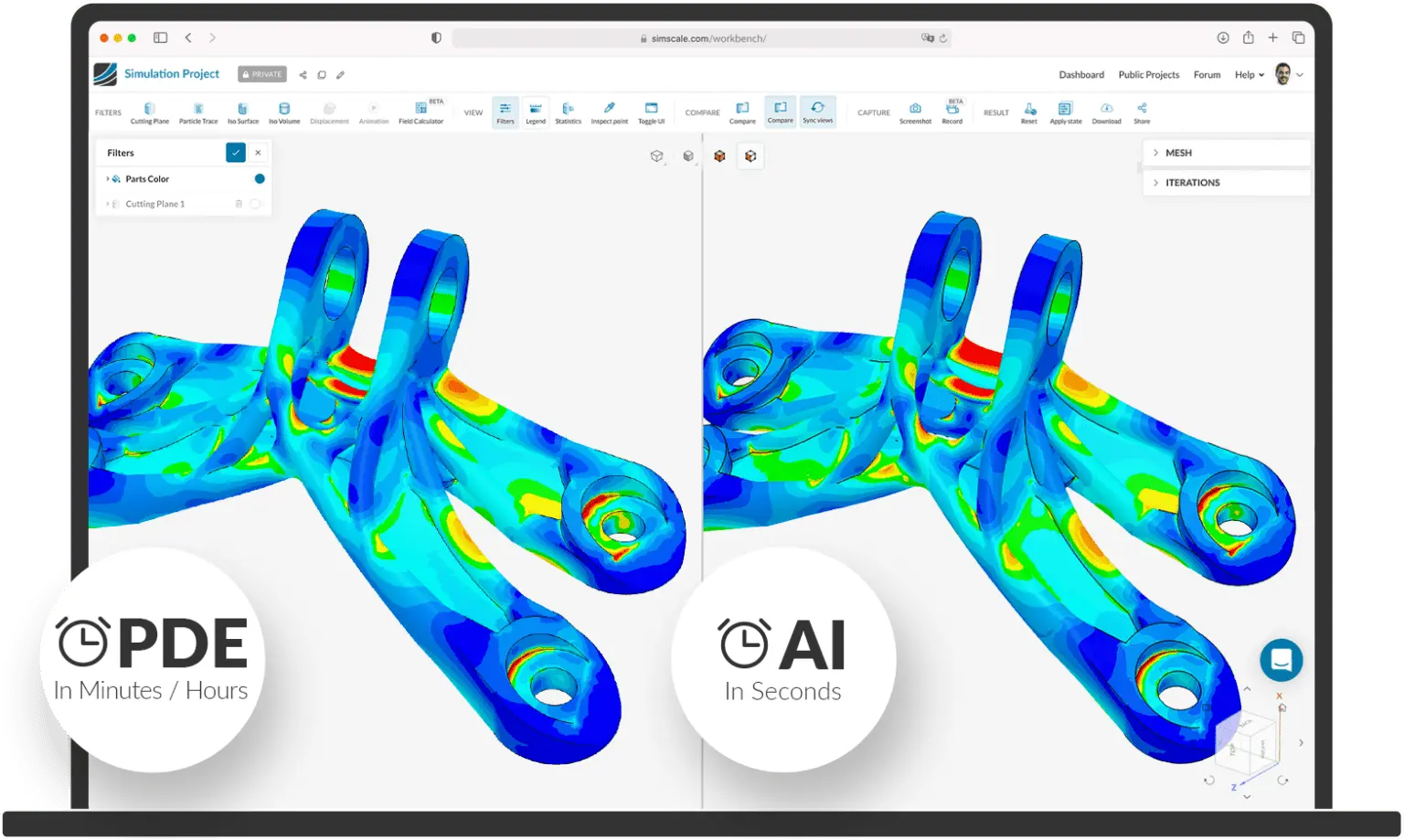

Simulation data is persisted in a way to directly be used for AI training (i.e., hardware selection process is done via AI models. More in progress.)

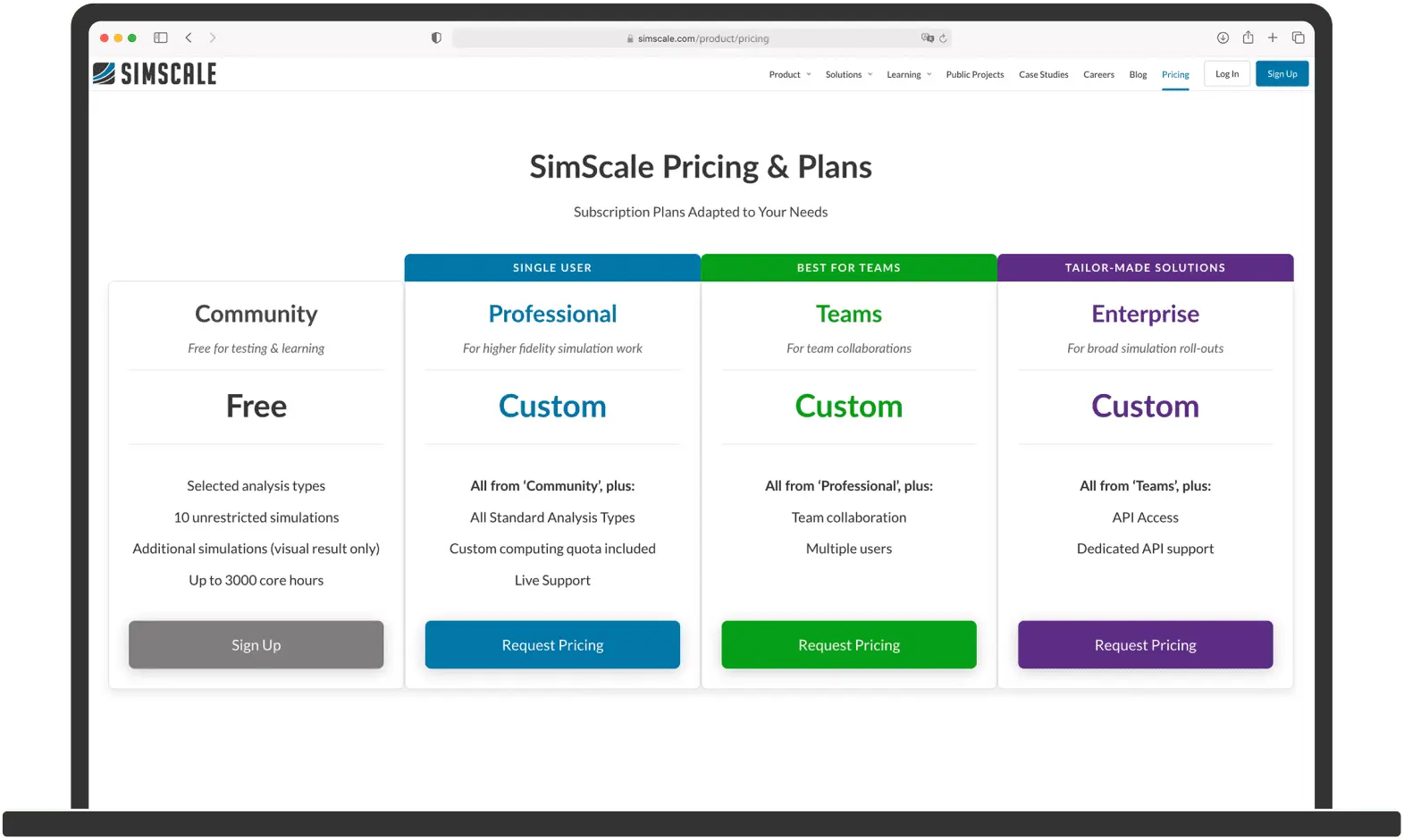

Capex-free, low ‘total cost of ownership’. Economically viable from a single user to 100s of seats.

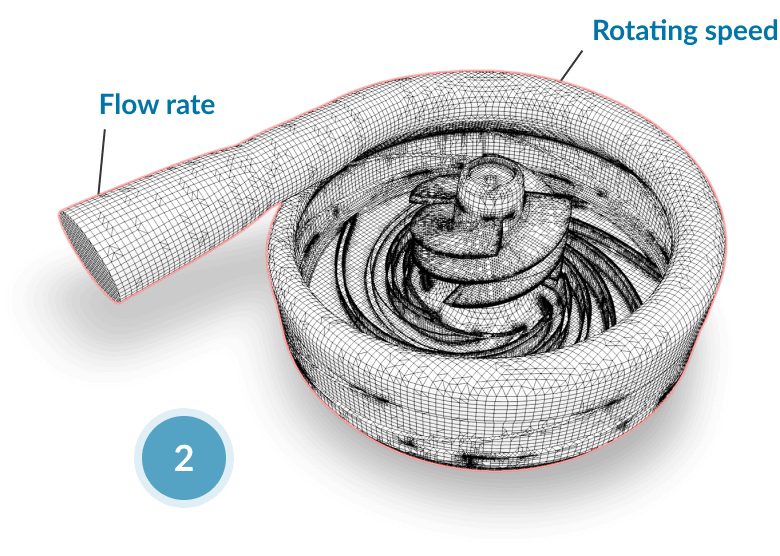

Upload or import

via CAD Plugins

Define physics and run

simulation in the cloud

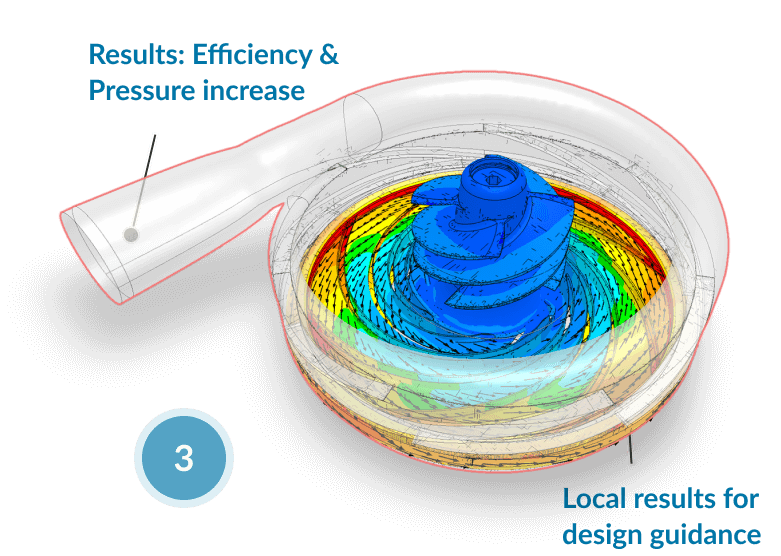

Review results and make better

design decisions earlier

Product lifetime

More power output

Lower pressure drop

Lower aero drag

Force reduction

Faster design-to-prototype cycle

Faster development

Faster pre-testing

Faster time-to-result

Faster cycle time

Saved per experiment

Fewer prototypes needed

Lower costs vs. lab test

Lower hardware costs

Fewer lab prototypes

Material savings

Lower mfg. costs

Material savings (per unit)

Less energy used

Smaller turbine size

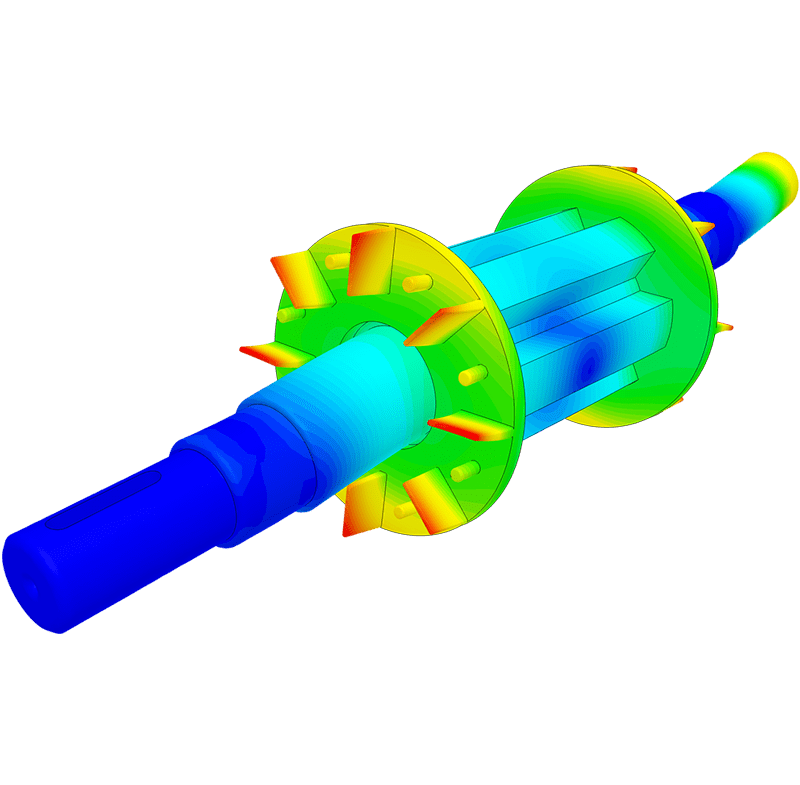

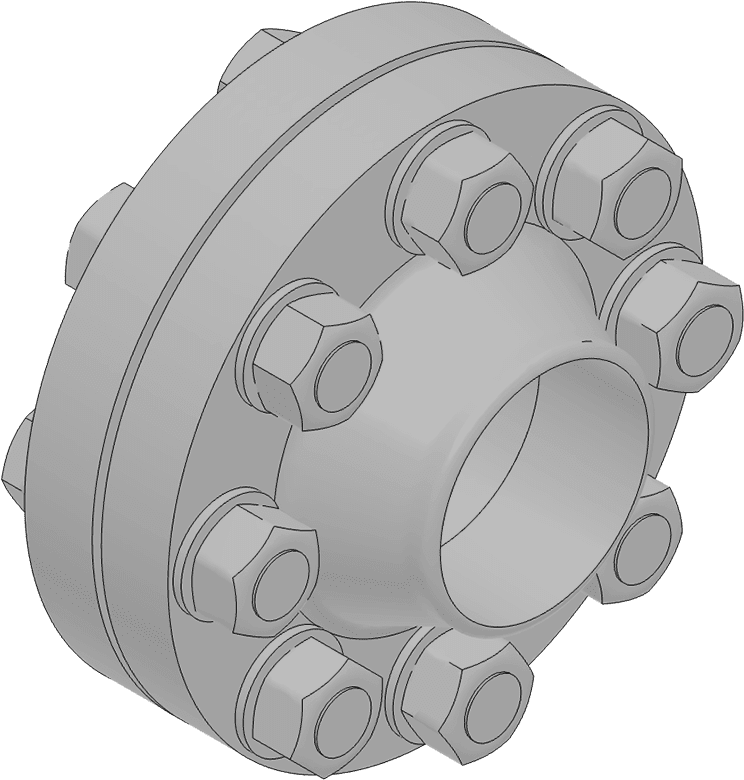

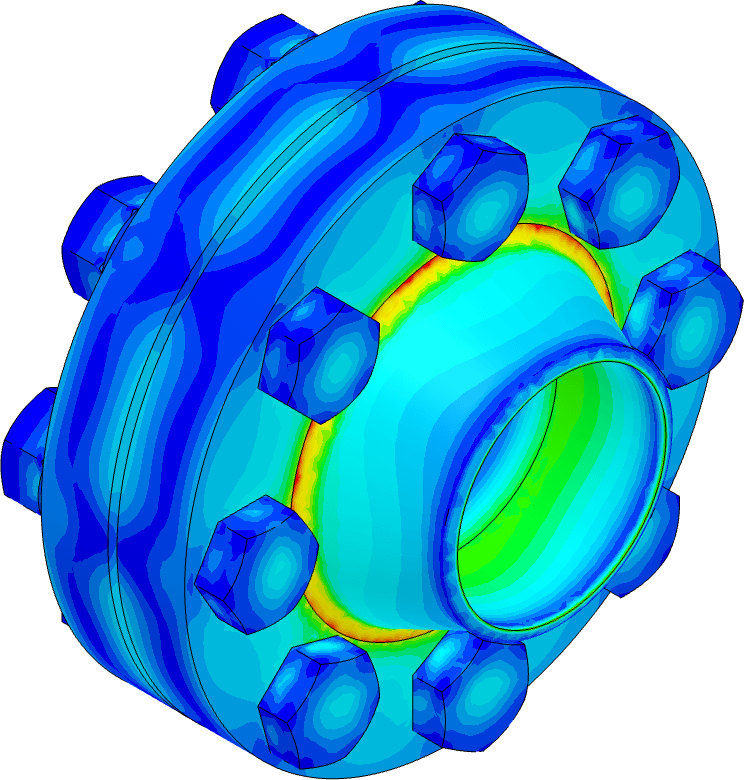

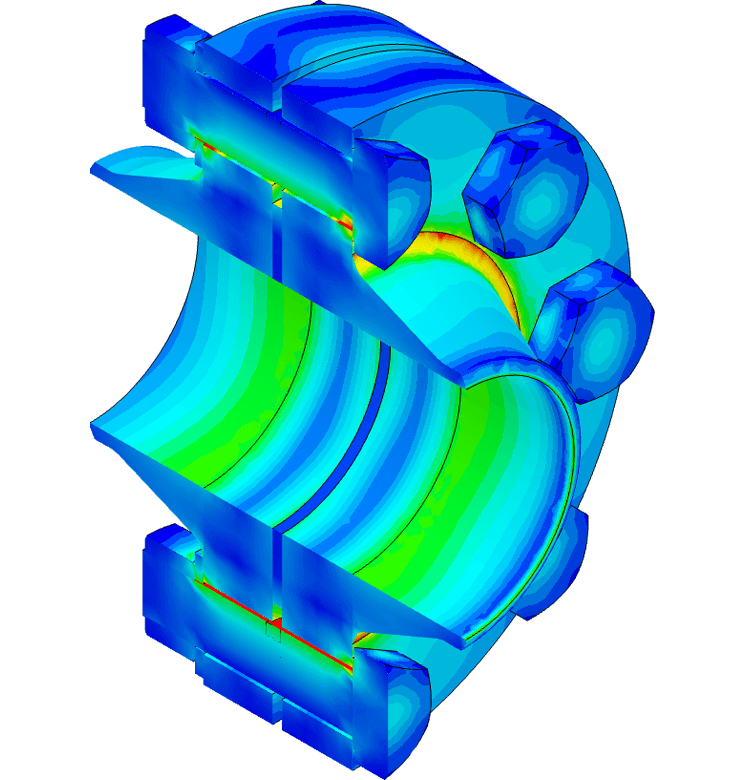

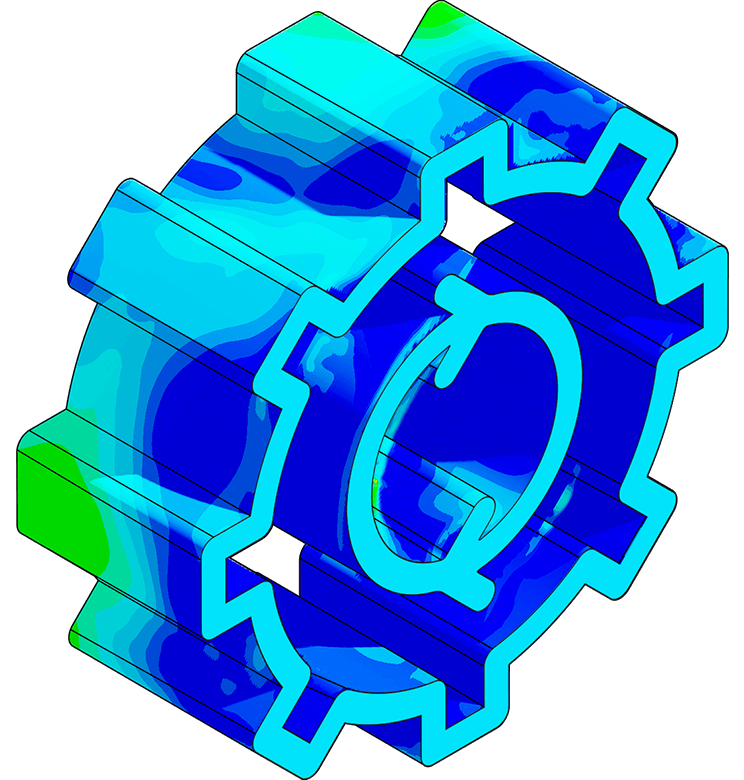

Stress & deformation, vibration, harmonic responses, transient dynamics, and more →

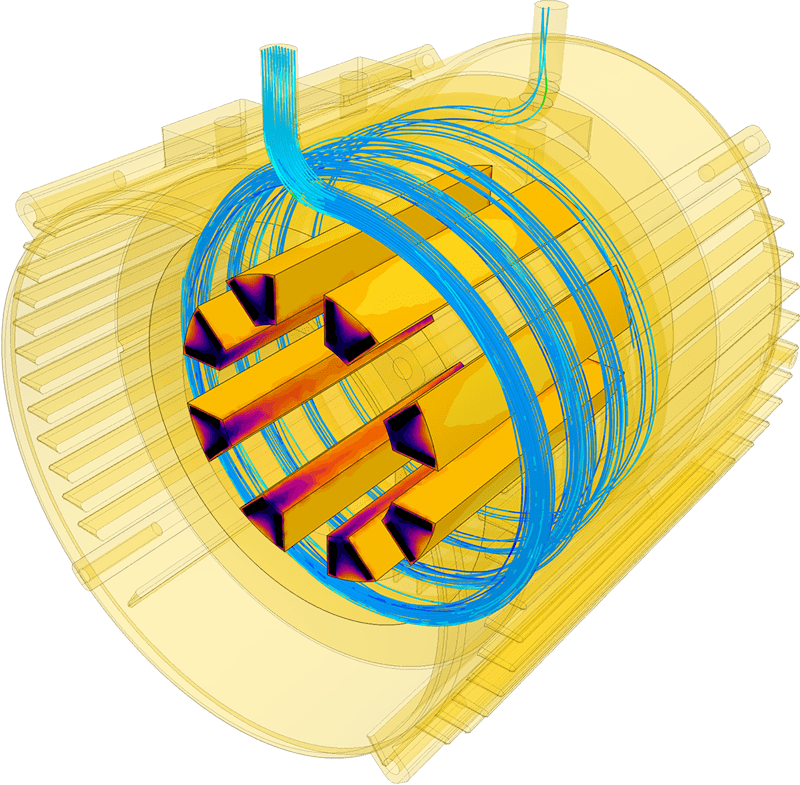

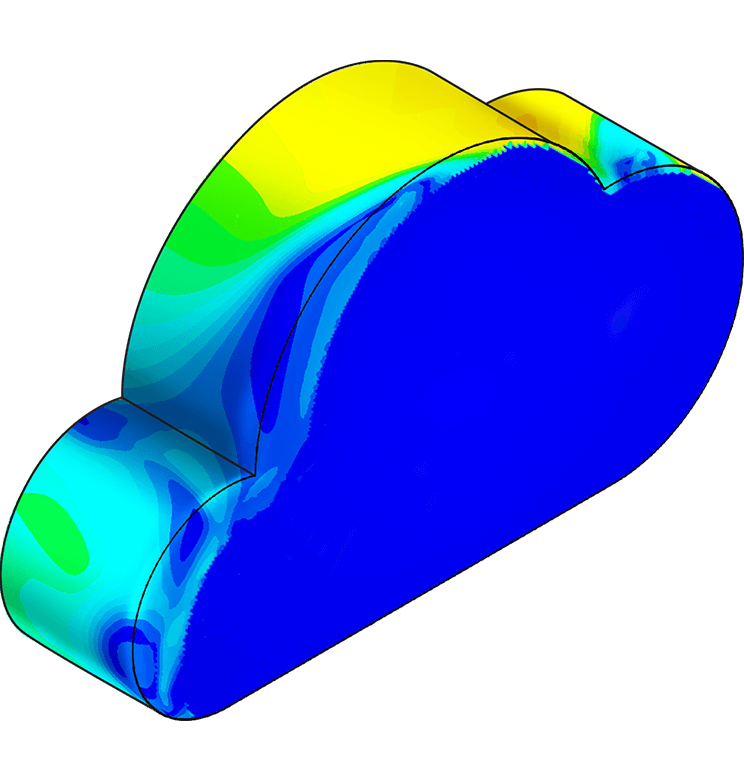

Coupled thermo-mechanical analyses, conjugate heat transfer, and more

Any CAD format, direct editing capabilities

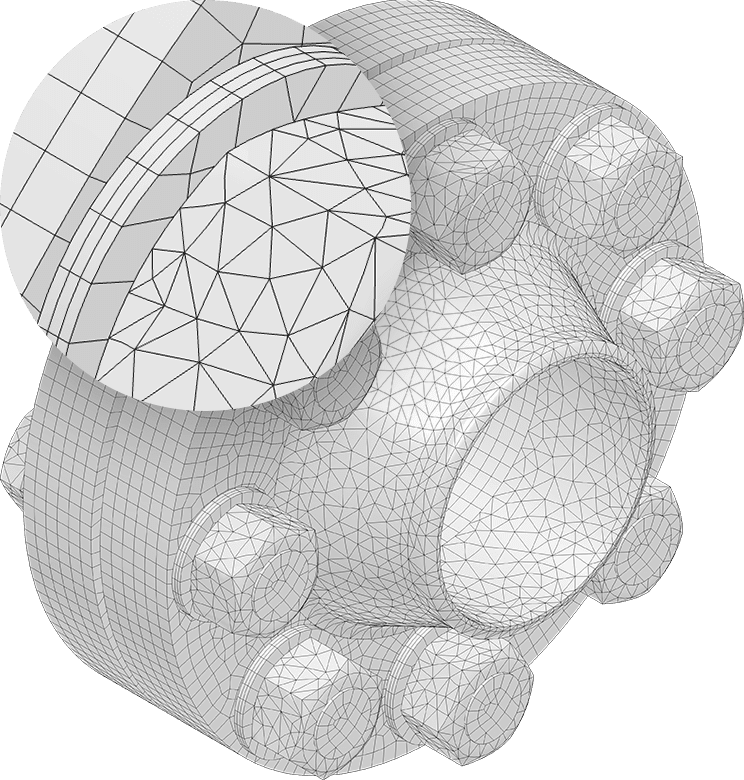

Automatic & manual, tet-, hex-, or polyhedral meshing

Best-of-breed solvers from each method (FV, FE, LBM, and more)

Integrated 3D post-processing environment

Manage simulation users, data, and processes in one place

Unlimited storage and computing capacity

Taught at leading academic institutions

Explore the community

Sign up for SimScale

and start simulating now