Trond Gudmundsen is a technical engineer with a background in blacksmithing and construction welding in Oslo, Norway. He started his consultancy office Designcraft in 2010 and works with his customers in metal construction design and general product development projects. Currently, he is working on a project for DeepRiver AS, a company that is active in the research and development of power plants that produce electricity from slow/fast moving river, ocean, and tidal currents.

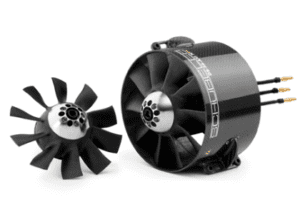

DeepRiver AS needed to test the energy efficiency of its turbine design called the Pilot Turbine to determine which design solutions would improve its product. The physical prototype was based on an old water wheel concept, which was full-scale tested in Klapeida, Lithuania.

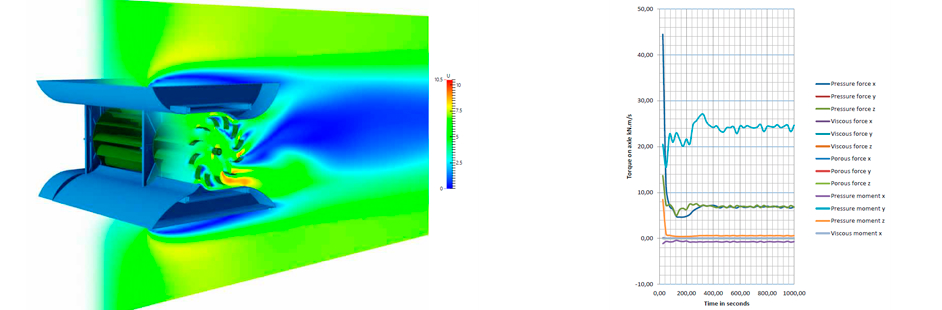

Although paper calculations gave a promising expected efficiency and the physical test also showed good results, it was still important to deeper understand the behavior of water through the turbine construction; for example, how the pressure is distributed on the turbine blades.

The project then moved to a critical stage, where modifications and improvements to the design had to be implemented in the technical drawings for the construction of the final turbine version.

SimScale's customer support is positively surprising, because usually the customer pays a lot of money but needs to wait days or even weeks for support reply. SimScale service has a very clear structure, that one account manager and one support engineer are my only points of contact to listen to my request, and positively keep me updated.

Trond Gudmundsen

Founder

For the validations, Trond considered investing in on‐site testing with an on‐premise CFD simulation software license, however, the costs proved to be too high. While searching for a more optimal solution, Trond learned about SimScale, a powerful, cost‐efficient, numerical analysis tool that could be used to verify each of the design changes before the company started the production.

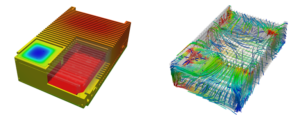

With SimScale, Trond was able to set up and run CFD simulations to better understand the local conditions and analyze parameters, including flow rate, turbulence, frequency, and the rotations effect on flow.

Firstly, Trond ran 2 simulations on the pilot turbine. Physical tests and simulations matched each other’s conclusion, and both made it obvious that the turbine construction should be more streamlined. Later, incremental changes to the design were made. Each version was tested using simulation until the final version was ready.

The simulation results helped Trond to better understand how to capture pressure to obtain more energy from the water flow, and how to avoid unnecessary turbulence and drag. The simulations have also contributed to increasing the effectiveness of the turbine design. Although the optimized turbine construction is reduced by 30% in size, it has almost half the number of turbine blades and a smaller diameter, the new design is still as effective as its predecessor.

With on-premises simulation software, it would have taken one hour to prepare the geometry, one hour to set up the simulation, and up to 49 computing hours to complete one run. With SimScale, on the other hand, the processing time was dramatically decreased to 1,5 hours in real time on 32 cores (48 hour computing time on 32 cores).

Furthermore, with the ability to run multiple simulations at the same time, Trond was able to use up to 150 computing hours in just 2 working days. The progress bar on the platform, as well as the e‐mail notifications also gave him a clear overview of ongoing and finished work, and let Trond better control the pace of client projects.

Although the optimized turbine construction is reduced by 30% in size, it has almost half the number of turbine blades and a smaller diameter, the new design is still as effective as its predecessor.

Sign up for SimScale

and start simulating now