In this SimScale student success story, we engage with Team Maverick from Pimpri Chinchwad College of Engineering (PCCoE), India, as they unveil their transformation in enhancing aerodynamics through SimScale. Beginning with an exploration of UAVs, their diverse applications, and the upcoming competitions in which the team is participating, this narrative sheds light on Team Maverick’s navigation through challenges and innovative strategies.

Team Maverick, an aero design engineering team, is dedicated to designing, innovating, fabricating, and testing fixed-wing UAVs. The team is currently engaged in two prominent competitions scheduled for the 2024 season. Initially, they will participate in the SAE Aero Design Challenge (ADC) International taking place in California. This globally renowned competition draws in approximately 75 teams from around the world, offering a platform to showcase aerodynamic innovations and skills on an international platform. The challenge to design UAVs embodies a vision for the future, where engineering prowess meets technological advancement. It is an opportunity for students to leave an indelible mark on the world, shaping the trajectory of UAVs and unlocking their limitless potential.

Additionally, the team is preparing for the SAE Design and Development Challenge (DDC) India in Chennai. This national competition unites around 87 teams from across India, providing a common ground for colleges to test and demonstrate their aircraft’s aerodynamic capabilities. Both competitions present significant opportunities for the team to excel on both global and national levels.

“Efficiency redefined: SimScale minimises computing demands and maximises productivity.”

– Team Maverick

A Look Into Unmanned Aerial Vehicles (UAVs)

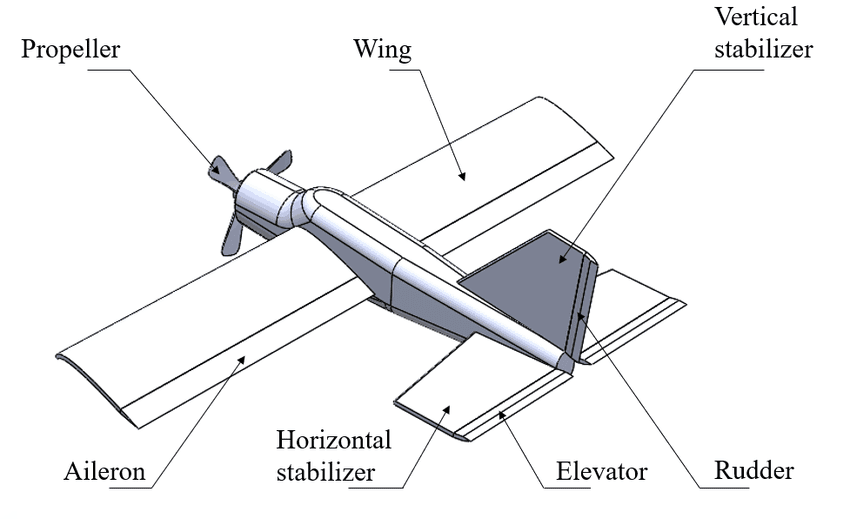

Before diving into Team Maverick’s journey, it’s crucial to understand the pivotal role that Unmanned Aerial Vehicles (UAVs) play in modern aviation. Fixed-wing UAVs, often recognized for their likeness to conventional airplanes, rely on wings to create lift while in motion through the air. This design, a common variant among UAVs, has revolutionised industries by offering extended flight ranges and remarkable endurance. These aircraft offer extended flight times and faster speeds compared to rotor-based models.

Available in various sizes and configurations, from compact drones to large reconnaissance units, they cater to diverse sectors like logistics, agriculture, and surveillance. Technological advancements, including AI-driven autonomy and improved battery efficiency, signal an even more integral role for UAVs in everyday operations. As regulations evolve to integrate them into airspace seamlessly, the future of UAVs promises increased efficiency, safety, and expanded applications across industries.

Team Maverick: Aeronautics & Beyond

Team Maverick describes its core objective as providing students with a transformative aerospace experience. Beyond aeronautics, the team focuses on developing project and resource management skills, fostering collaboration, and ensuring industry rules and regulations compliance. With a commitment to contributing to the expansion of the field, the team is devoted to building cutting-edge aircraft for future applications and societal impact.

“We aim to produce technologically skilled, socially responsible, and aesthetically conscious engineers.”

– Rifa Ansari, Team Maverick

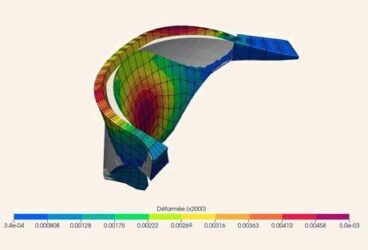

Every component of the aircraft they designed underwent extensive study and analysis, considering various aerodynamic parameters like wing lift and drag, empennage characteristics, and the overall aircraft performance. Determining downwash and vortex production by simulating wing behavior was a crucial aspect of their work. Additionally, they employed structural analysis methods to evaluate the strength and integrity of each individual component.

Analyzing Aerodynamics and Structural Integrity with SimScale

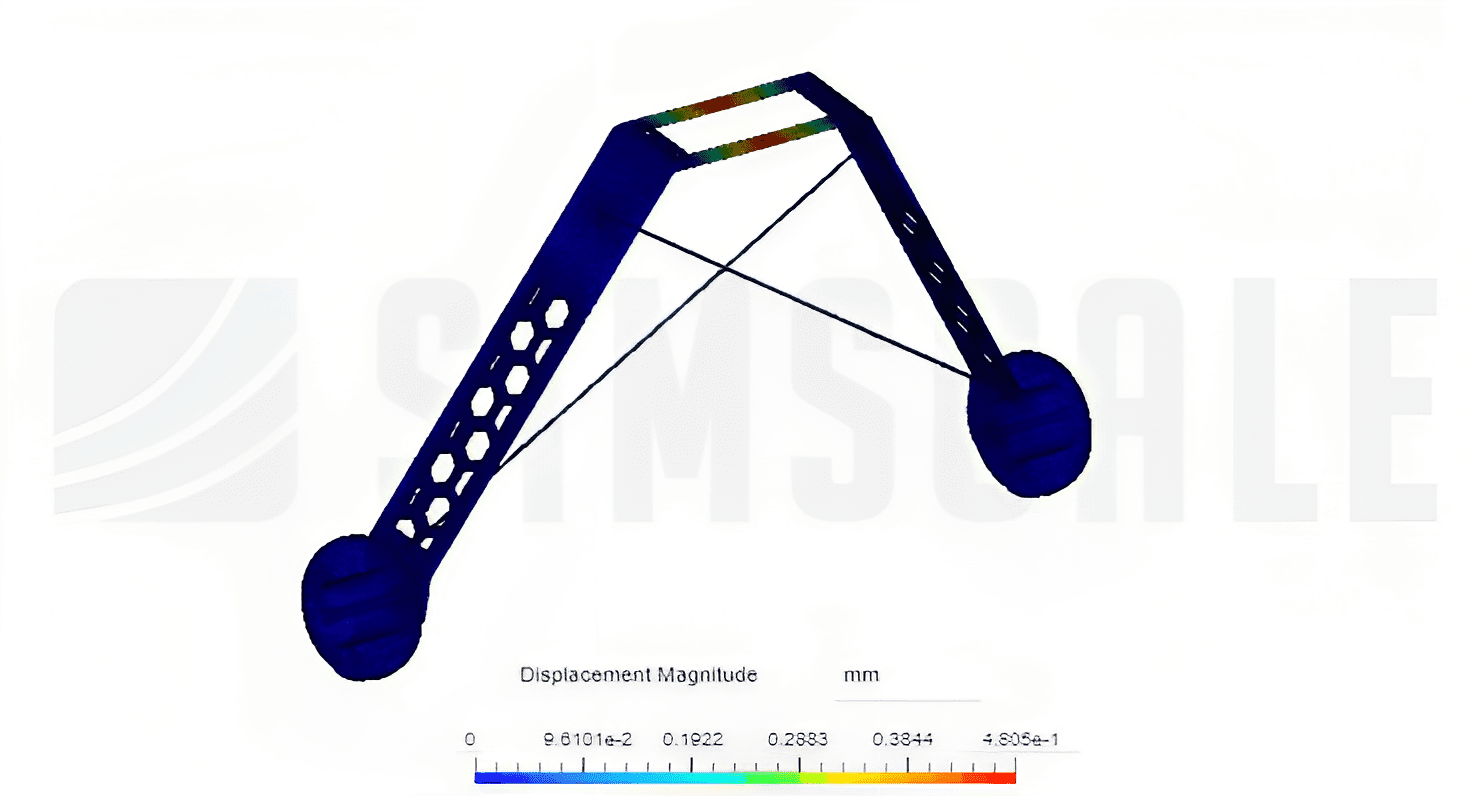

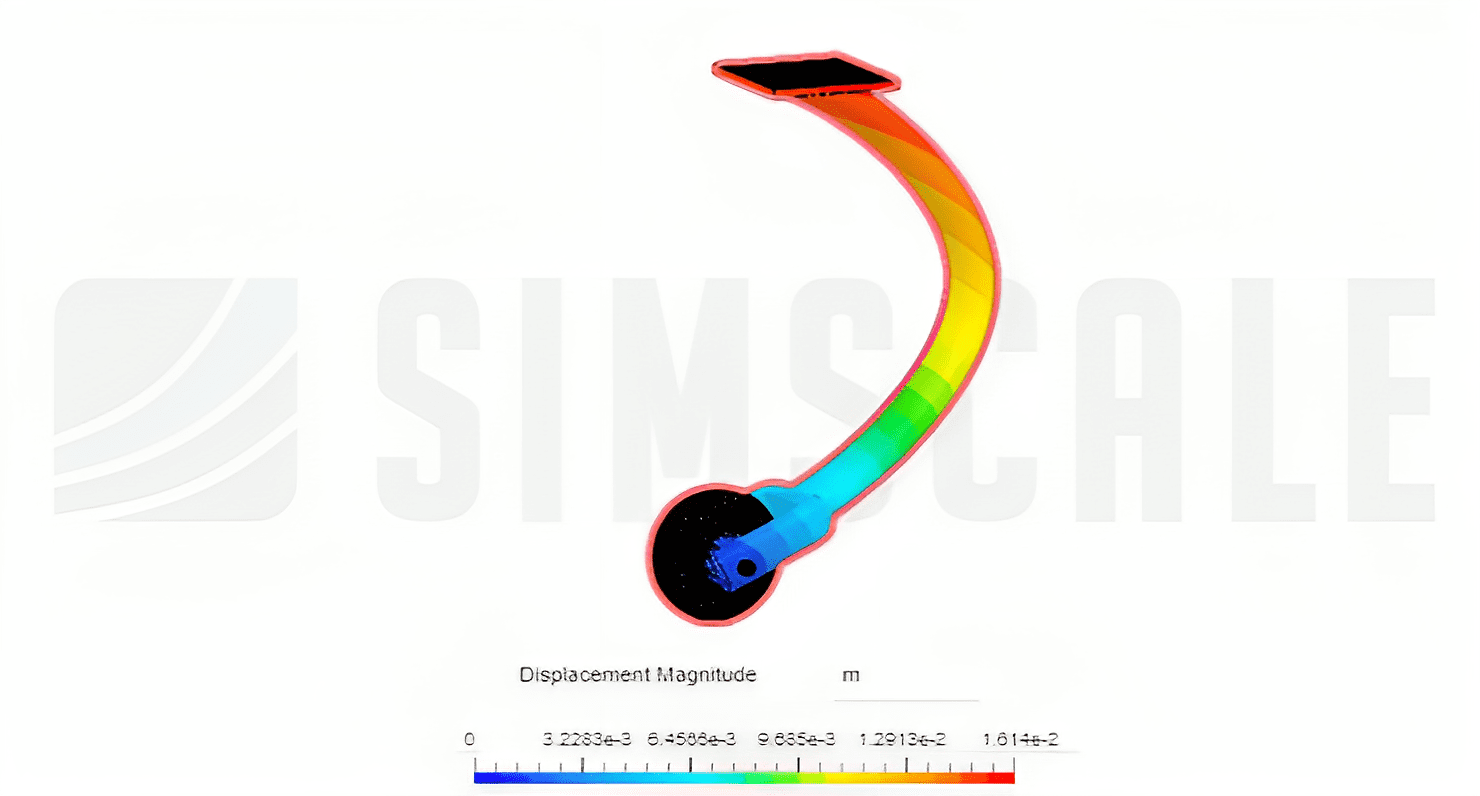

The team conducted simulations on various iterations of the wing, empennage, fuselage, and the entire aircraft, assessing different parameters such as takeoff and cruising conditions. To understand the aerodynamic performance of each section of the aircraft and evaluate the airflow around the entire plane, a steady-state laminar incompressible flow simulation was performed. Static structural analysis was carried out to better understand the structural integrity of components and to identify potential failure sites in the aircraft. The online tutorials provided by SimScale were instrumental in establishing the fundamental workflow for their project.

How SimScale Helped Address Challenges

The team encountered several challenges throughout the project, including difficulties with report generation, failure to generate lift and drag graphs, lower result accuracy, and issues with contact detection among multiple components.

“SimScale revolutionizes simulation with its cloud-based platform, eliminating the necessity for costly hardware. Its automated meshing tool generates top-tier computational meshes, while seamless integration with leading design applications, simplifying simulation setup. The SimScale Workbench serves as the hub for creating and overseeing simulations, offering an intuitive interface for defining setups with ease.”

– Rifa Ansari, Team Maverick

To tackle these obstacles, they sought assistance from SimScale support through online meetings, effectively addressing most of the challenges. Additionally, the team leveraged the SimScale forum, where they posted queries regarding the encountered issues, receiving valuable responses that contributed to resolving their simulation challenges.

The simulation results were analyzed and validated with manual calculations and wind tunnel testing. The analysis generated results that were close enough to the practical wind tunnel test. The simulations, employing 32 cores, typically took an average of 120-150 minutes to complete from start to finish. However, for particularly complex geometry simulations, the process required additional time. Lift and drag values were majorly obtained along with the coefficient of pitching moment for control surfaces obtained to determine the hinge moment coefficient. The designed bodies’ total deformation and overall structural strength were evaluated.

The team found the platform to offer remarkable convenience and simplicity. According to them, SimScale’s standout feature lay in its ability to utilize multiple cores, surpassing hardware limitations and significantly reducing time constraints. Team Maverick was particularly impressed by the meshing component, which seamlessly aligned with their desired mesh quality, presenting numerous parameters. Furthermore, the platform’s visual interface for analyzing solutions was not only comprehensive but also visually appealing.

“Through analysis across multiple iterations, SimScale has played a pivotal role in enhancing our project’s overall efficiency. Conducting studies swiftly and seamlessly has minimized both the cost and time associated with building numerous prototypes. In essence, SimScale has been instrumental in streamlining development timelines, cutting costs, minimizing prototype iterations, and amplifying overall efficiency”

– Rifa Ansari, Team Maverick

Next Steps for Team Maverick

On incorporating simulation results into further product development, the team strategises to execute this process in stages. They will soon finalise the entire design by analysing and evaluating various iterations. Specifically, for function-specific requirements, they are investigating the aircraft’s shape and iterating internal structures to guide its form or enhance structural integrity using CFD analysis and structural analysis. Additionally, the team aims to conduct Fluid-Structure Interaction (FSI) and crash analysis to gain insights into the product’s real-world performance.

We’re confident that SimScale’s diverse simulation capabilities will greatly benefit the Team Maverick Student team in upcoming endeavors, and we’re eager for future collaborations. If your team seeks academic sponsorship for optimizing your aircraft’s performance, whether for the SAE Aero Design Challenge or any other competition – make sure to check out our Academic Plan for students who are joining design competitions.

References

- Cui, Aiya & Zhang, Ying & Zhang, Pengyu & Dong, Wei & Wang, Chunyan. (2020). Intelligent Health Management of Fixed-Wing UAVs: A Deep-Learning-based Approach. 1055-1060. 10.1109/ICARCV50220.2020.9305491