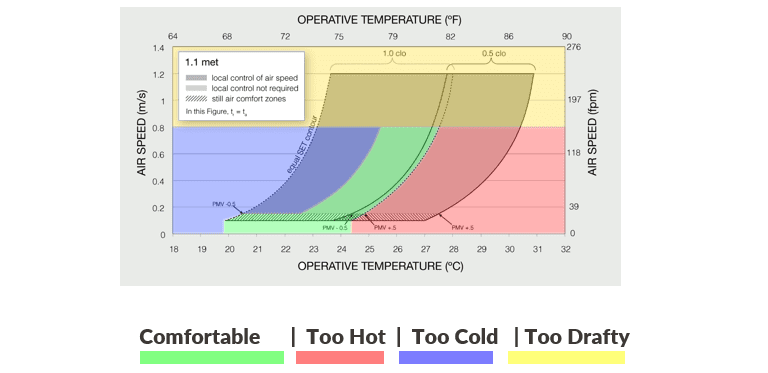

When designing an HVAC system—especially for large spaces such as theaters—you, as the engineer, face a large number of constraints. The final system needs to provide proper thermal comfort for the occupants, achieve energy efficiency, and still ensure that different industry standards, such as the ASHRAE Standard 55, are fully met.

Ashrae Standard 55 What is ASHRAE Standard 55?

ASHRAE Standard 55 (Thermal Environmental Conditions for Human Occupancy) has been in existence since 1966. It is published and periodically updated by the industry experts of ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). It is based on Fanger’s PMV index (a predictive rating scale), which is the most recognized model in thermal comfort research. It can also be found in international standards, such as Europe’s EN 15251 and ISO 7730 and China’s GB/T 50785 [1]. The ASHRAE Standard 55 thermal comfort conditions are less restrictive than Effective Draft Temperature (EDT).

The ASHRAE 55 standard is used for specifying the combinations of factors that produce thermally comfortable environmental conditions that will be acceptable to a majority of the occupants. It is a thermal comfort standard that is referenced by many green building rating schemes and is used for both commercial and residential spaces. ASHRAE Standard 55 takes into consideration the following personal and environmental factors: metabolic rate (met), clothing insulation (clo), air temperature, radiant temperature, air velocity, and relative humidity. [2]

While personal factors such as metabolic rate and clothing, cannot be influenced by the HVAC system designer, he or she can ensure thermal comfort by manipulating air temperature, airspeed, humidity, and other environmental factors.

For the purpose of this analysis, we will consider the following assumptions:

- Humidity Ratio = 0.1

- Radiant Temperature = Flow Temperature

- Occupants:

- 1 met (sitting)

- 1 clo (indoor winter clothes)

How CFD Simulation Can Help You Comply with ASHRAE Standard 55

Until recently, HVAC design engineers mainly relied on hand calculations in their efforts to comply with ASHRAE 55 and other standards. Today, with the advent of accessible and easy-to-use computational fluid dynamics (CFD) simulation tools, designers can virtually test and optimize their HVAC systems in the earliest stages of the design process. You can subsequently make alterations to existing designs based on the simulation results, intercepting design flaws early on, without the need to build physical prototypes.

To see a live demonstration of how CFD simulation can help you ensure thermal comfort in indoor spaces and comply with the ASHRAE Standard 55, watch this webinar:

Ashrae Standard 55 Case Study: Ensuring Thermal Comfort in a Theater Room through Ventilation

The project used for this case study can be freely accessed in the SimScale Simulation Project Library: Thermal Comfort for HVAC Design and ASHRAE 55.

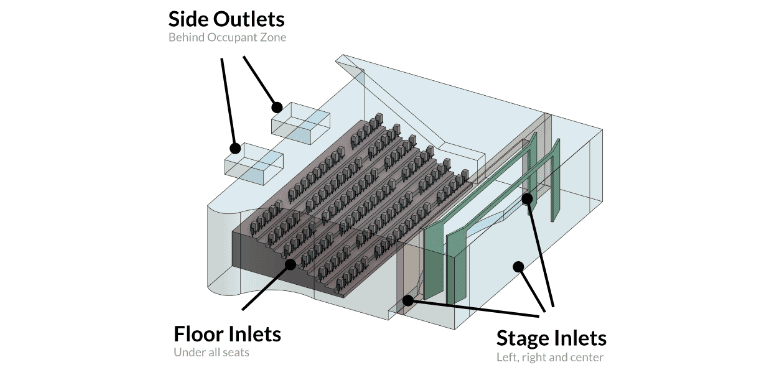

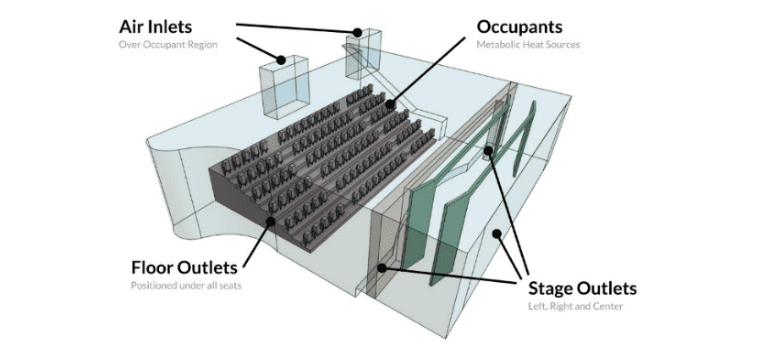

In this project, we will explore the design of an HVAC system for a large theater room, with the goal of improving the thermal comfort of the occupants inside. The main design decisions we will investigate in this particular analysis are the inlet and outlet ventilation locations. We will use SimScale’s convective heat simulation to analyze an initial outlet design configuration. From this analysis, we will design a second, better configuration where we address the identified flow issues. A follow-up analysis is then performed on the second, improved design configuration and the total improvements are highlighted.

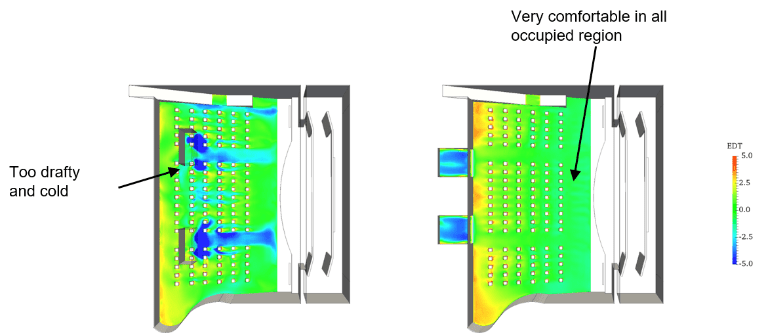

The second design goes into a completely different direction, the inlets were placed underneath the seats and at the stage floor (the outlets of the previous design), and two large outlets were placed behind the last row of occupants, in the room’s back wall. This kind of design was recently used in a large performance show’s room [3].

Simulation Results

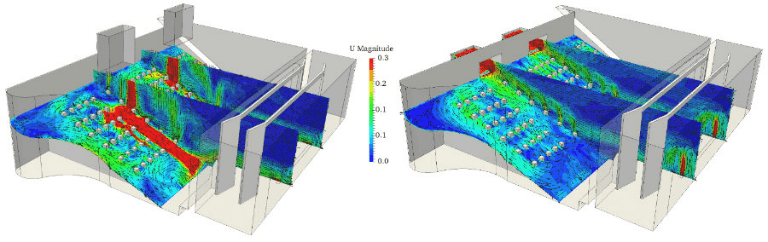

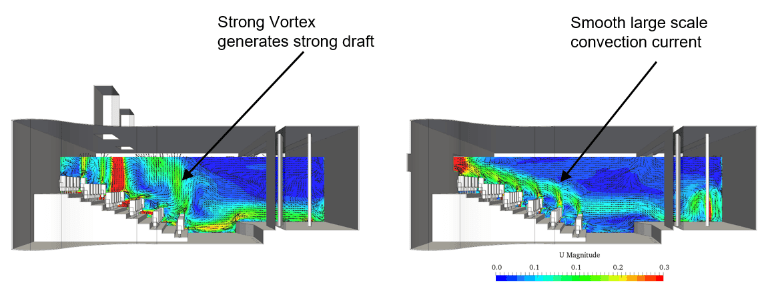

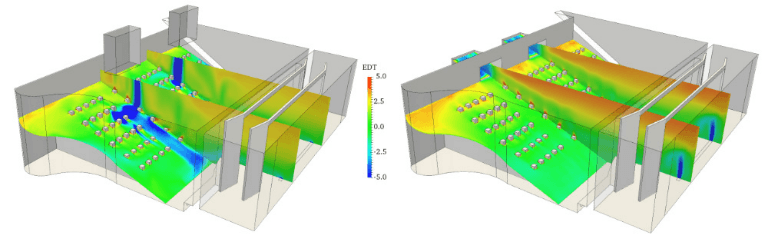

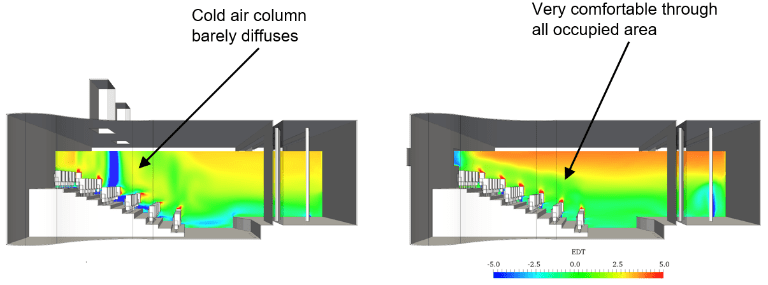

CFD simulation allows us to analyze the detailed aspects of both designs by visualizing the airflow velocity and direction, the air temperature, and the effective draft temperature (EDT), which combines the velocity and temperature information.

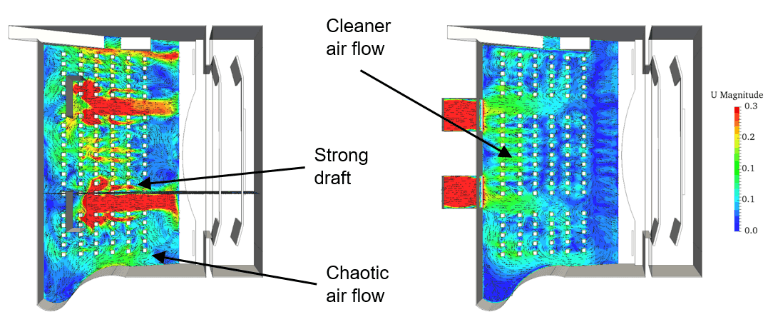

Air Velocity

Very strong drafts can be observed in the occupied region of the first design. The flow from the inlets is very poorly distributed through space, and the flow around the occupants is dominated by small-scale erratic vortices. The second design, however, reveals no strong drafts near occupants and a relatively large convection current renewing air near the occupied area.

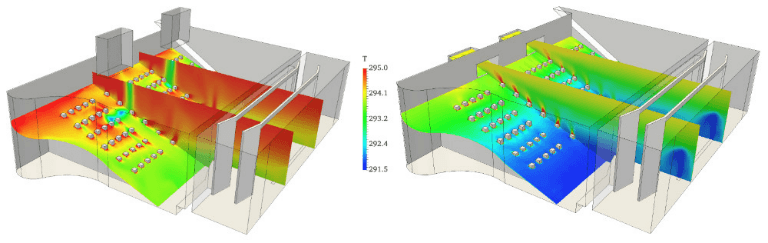

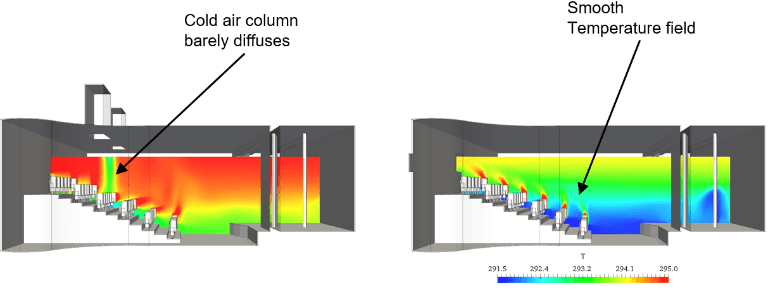

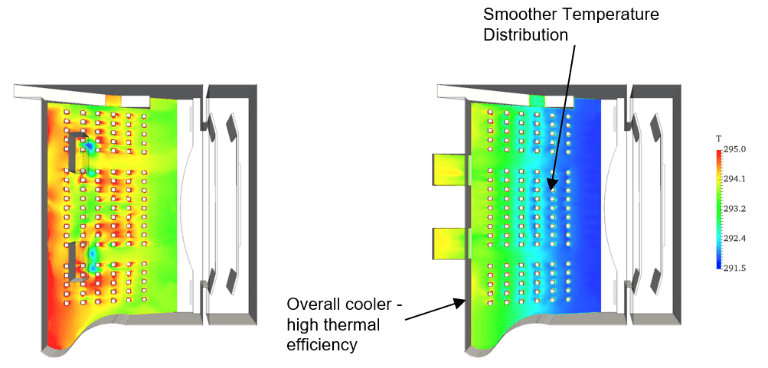

Temperature

The simulation revealed large temperature differences throughout the occupied region, with some occupants getting exposed to very cold air. The thermal efficiency is also poor, as evidenced by relatively warm air. In the second configuration, all occupants are within the temperature comfort region, and the air temperature shows greater stratification.

EDT

In the first design, a large number of occupants find themselves outside the comfort standard (–3°F<EDT<+2°F). On the other hand, no discomfort can be observed for any occupant location, and occupants are well within the comfort limits.

Ashrae Standard 55 Conclusions

The simulation results reveal significant flaws in the first design, including strong drafts near the occupants, large differences in temperature across occupants, with many occupants seated outside of the thermal comfort zone. The area directly underneath the inlets is particularly thermally uncomfortable. The second design clearly shows a significant improvement; the air patterns are optimized and no drafts or large temperature gradients can be seen near the occupants.

Overall, the above post-processing images reveal vast differences between the two designs, with the second one being clearly superior in terms of thermal comfort. With a few simple modifications to the original ventilation system design, the overall thermal comfort was improved dramatically. The whole simulation took only a few hours of manual and computational time, but it allowed us to identify the flaws and test potential design improvements. Whatever design idea you might have—no matter how unconventional—with virtual prototyping you are only a few clicks away from predicting its performance.

So why aren’t all designers using simulation yet?

-

Accessibility: Traditional software needs to be installed locally on expensive high-performing computers, the majority of which remain idle most of the time. With SimScale, all computations are cloud-based—all that is needed is a web browser.

-

Operating costs: Standard commercial simulation software packages are notoriously expensive. With SimScale, there is an option to start simulating right away with a free Community Plan.

-

Know-how: Most modern tools are designed for experts and experienced simulation engineers. To bridge that knowledge gap, SimScale offers a large public projects library, free training, and live support chat.

Don’t forget to watch this free on-demand webinar to learn more about using CFD to ensure thermal comfort and comply with the ASHRAE Standard 55:

If you want to read more about how CFD simulation helps engineers and architects improve building performance, download this free white paper.

References

- http://www.healthyheating.com/Myth_No.3.Thermal_Comfort_too_complicated.htm#.Wn1qR6inHIU

- ASHRAE Standard 55, Thermal Environmental Conditions for Human Occupancy, https://www.ashrae.org/resources–publications/bookstore/standard-55-and-user-s-manual

- https://www.csemag.com/single-article/hvac-design-for-a-performing-arts-center/3ebe6ec4adc10aff1f0ca22ad25ddf3f.html