A light-emitting diode (LED) is a semiconductor device that emits light when an electric current passes through it. LEDs are common in consumer electronics, and they need to have a proper cooling mechanism (usually a heat sink) as the temperature can affect the LED performance over the product’s lifecycle.

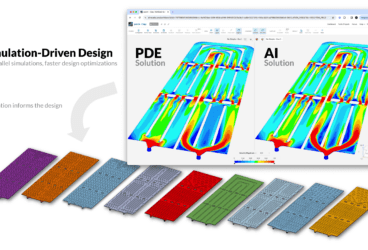

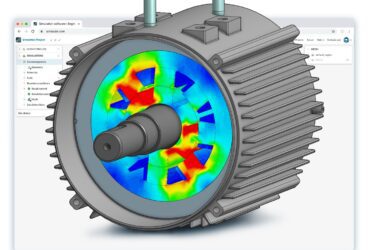

Using the usual Design – Build – Test – Redesign approach to assess a heat sink’s cooling efficiency is time-consuming and expensive. Designers are now turning to CFD, FEA, and thermal analysis to evaluate, test, and optimize designs virtually before they are built, saving production time and cost. Using online simulation cuts production costs even further because they eliminate the need for a high-powered computer.

Thermal simulation is the computerized method to study the heat dissipation efficiency of a heat sink both in conceptual and detailed design stages. With SimScale, engineers can quickly analyze heat sink designs for thermal resistance and conductivity, using only a web browser. They can even compare different types of heat sinks, including active, passive, stamped, single fin, forged, and more.

Studying the Heat Sink Cooling Performance for Different LED Packages

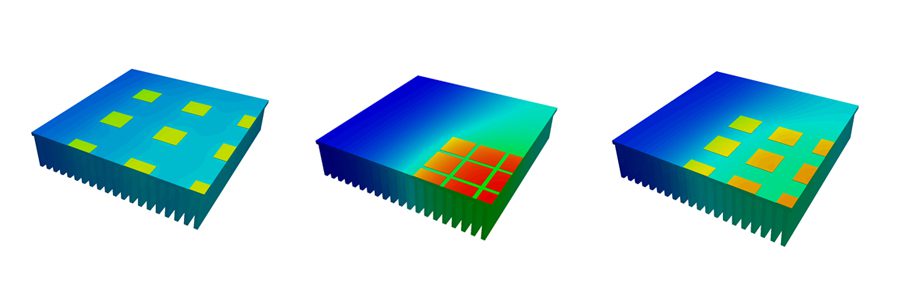

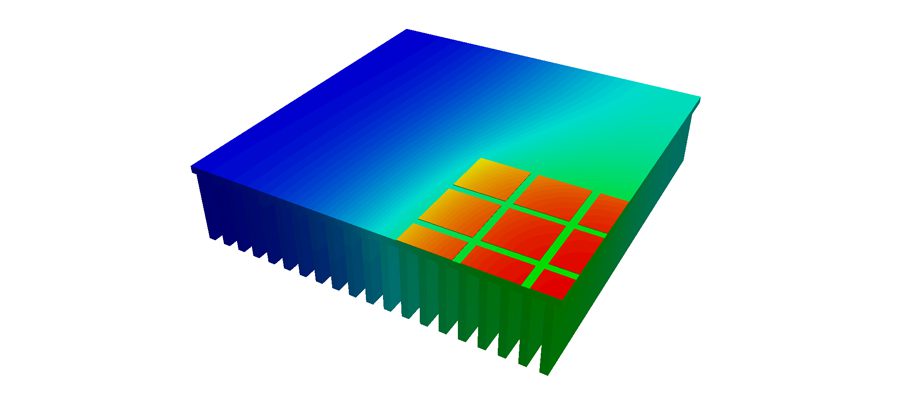

This heat transfer analysis was performed on three different Light Emitting Diode (LED) packages used in consumer electronics. This analysis focused on evaluating the cooling performance for several different array placements of LEDs.

In order to show the utility of SimScale, and how it can be used for LED cooling, the analysis took the highest temperature for the LED packages with a pitch of 1 cm (left), 5 mm (middle), and 1 mm (right) on different operating power were compared to experimental data.

The comparison clearly shows a major difference in the results of the 1 mm pitch package. This clearly indicates that the narrow placement of LEDs resulted in a poor cooling performance, as shown in the figure above. In conclusion, if a narrow placement is required, the design of the heat sink needs to be optimized.

For a detailed study, visit the Thermal Effects in High Power LED Packaging documentation. To learn more about heat sink simulation with SimScale, visit this dedicated page.

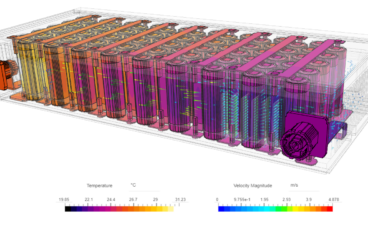

Despite the significant manufacturing cost reduction of electronic boards and prototype enclosures for devices, it is still a daunting and time-consuming task to analyze the thermal performance of a new design. Download this free case study to learn how the thermal performance of a printed circuit board was investigated with SimScale.