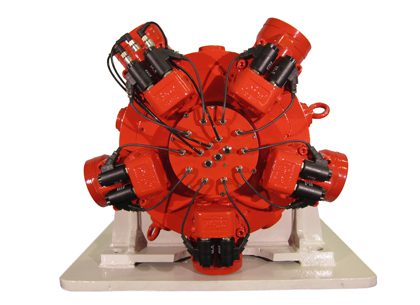

Working on the improvements of their hydraulic motor valve designs led the Diinef team to engage with computer-aided engineering (CAE). The operation of the valve involved opening and closing it while experiencing very high pressure differences (up to a few hundred bars). It was expected that these conditions would be accompanied by cavitation, which posed a risk of damaging the valve during prolonged operation.

Two targets were set for the CFD analysis:

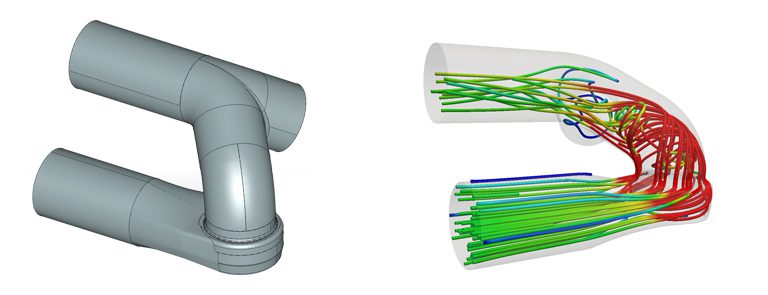

The initial analysis included a compressible flow simulation of the whole 3D valve at an early stage of the opening process. The geometry consisted in the basic shape of the valve, which allowed the Diinef team to obtain the results very fast. At the same time, the gathered information already allowed them to take the first engineering decisions.

It was also observed that simulations of the full valve configuration were not necessary and a more focused analysis of the opening gap was undertaken. This allowed a quick iteration of different shapes. The development process was speeded up even more when the analysis was shifted to a semi-2D model.

The straightforward approach to the problem enabled the Diinef team to easily analyze the obtained results and perform fast design iterations. The first positive result was the reduction of the pressure drop on the slightly open valve by 80%, which put it within the desired operation range. The simulations also indicated a redirection of the flow. This moved the zone of potential cavitation several millimeters away from the wall. Physical tests of the valve confirmed the reduction of the back-pressure drops.

The cavitation phenomenon was still observed and it was difficult to judge if the actual tendency was removed. At the same time, the knowledge gained from simulating the phenomenon with SimScale drove the team to include extra material in the risk zone to prevent any possible cavitation damage.

Approaching the design process using simulation with SimScale allowed Diinef to avoid a costly and slow testing process of physical models in the early stages of the project.

Sign up for SimScale

and start simulating now