Founded in 2012, Malaika (translated as ‘baby’ or ‘angel’ in Swahili) was initially started to create a more lightweight and user-friendly car seat. However, the company quickly broadened its approach to include safety features, to ensure the highest possible level of safety for child car seats that technology permits.

The worst situation any parent could imagine is the loss of a child. Every year in Europe alone, 400 children die as a result of motor vehicle accidents and another 2,800 suffer serious injuries causing permanent disability. The forces at play in these accidents can be enormous and quite often the resulting injuries sustained by children are greater than those sustained by the adults in the vehicle.

So how can the crash forces on children be reduced and safety increased? To tackle this issue, the engineers at Malaika have designed the world’s first range of child car seats to surpass every international safety standard, effectively raising the bar for child vehicle safety.

We believe that children in cars should have the highest possible level of safety that technology permits. We don’t feel like we need to be satisfied with what we have today, we actually want to deliver something that makes it better.

Karl Hearst

CEO Malaika

To meet such an extreme design challenge, the engineers at Malaika implemented rigorous product testing and design verification procedures at both the component-level and system-level. The SimScale platform has been a requisite part of this process and a series of component simulations have been done to validate the structural integrity of the primary ISOfix connection to the main chassis and the adjustment rack. As a supplement to physical testing, structural simulations were conducted with SimScale based on worst case scenarios to a force of 3600 N.

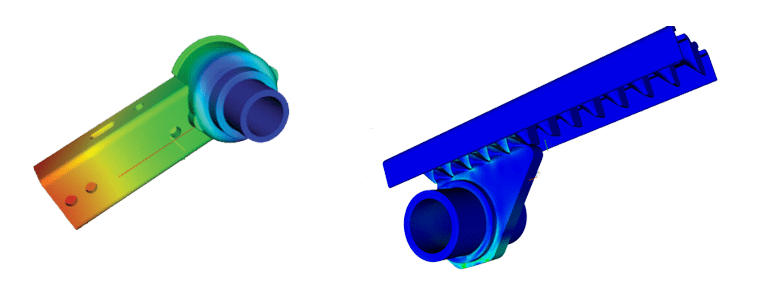

The primary ISOfix Connector is a steel component that attaches the adjustment bar on the base of the car seat to a fixed anchorage point in the vehicle’s body. In a crash, it is a critical component for ensuring that the car seat remains in place. The impact force is applied to the 4 bolts at the base of the connector. There is a sliding contact between the adjustment bar (which is fixed) and the circular connector head.

A second rim has been added to the circular connector head to increase the rigidity and strength of the part. As the simulations show, high-stress zones are present on the circular connector head and near bolt holes. The greatest displacements are seen at the base of the connector where the forces are applied. These are very small, however, and do not introduce design concerns.

The length adjustment rack is part of the base of the car seat and consists of a set of grooves into which steel teeth from the adjustment bar fit. Sliding occurs between the grooves and teeth when a force is applied. There are significant stresses at the locations of contact under the worst case loading conditions. Under these simulation conditions, the highest stresses occurred at the middle tooth.

These stresses exceed the tensile strength of steel, which means that material yielding is occurring. Locating these zones of yielding provides information as to where additional design considerations should be made before physical testing is done. Having launched its car seat, the Malaika team planned to continue using structural simulations with SimScale to frequently test the designs and reduce the number of required physical prototypes. As a complement to physical testing, the SimScale platform completes the design cycle.

The stresses exceed the tensile strength of steel, which means that material yielding is occurring.

Sign up for SimScale

and start simulating now