One of the projects of SolidTrust was the optimization of a car muffler design’s performance, which is determined by three main factors:

At the same time, the design of a muffler also influences the amount of noise generated by the gas exhaust. SolidTrust carried out CFD simulations with SimScale to test and analyze the flow patterns within different proposed designs of the muffler, as well as to measure the pressure resistance of the device.

Being a cloud-based platform, SimScale helped us run more simulations and consequently iterate more design changes, compared to traditional on-premises CAE solutions. The ease of login and work in a web browser further adds to the most interesting part of SimScale, which allows us to work anywhere and anytime.

Manisankar V.

Head of Technology at SolidTrust

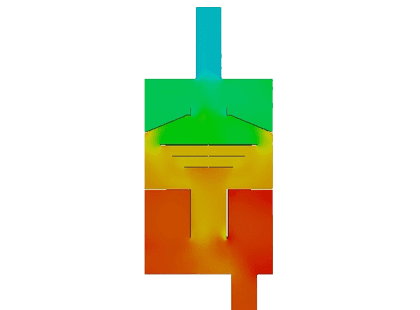

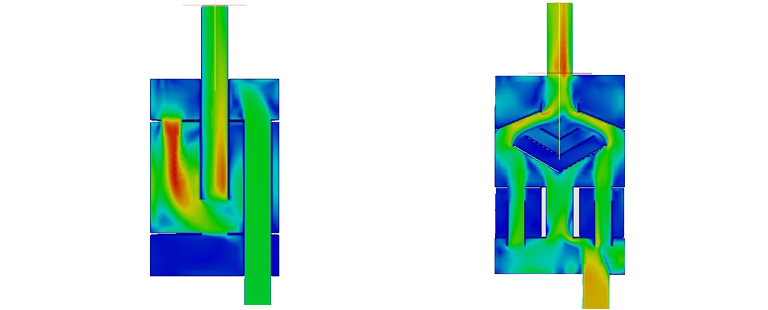

For the numerical analysis of the flow, an incompressible, turbulent airflow model was chosen. The inlet conditions were kept at engine operating conditions of 28mps. The obtained data were analyzed with the aim of acquiring pressure drop from inlet to outlet, high and low air velocity areas, and overall flow patterns within the design.

A CFD analysis was performed on the original design of the manufacturer (OEM). The muffler included simple, long pipes inside 3 chambers. The results from this simulation were later used as a reference point for the improved designs.

The first proposed modification of the muffler involved the shortening of the inlet and outlet pipes. A complete redesign of the internal part of the chamber was performed, i.e., extra flow diverters were added and three rows of straight fins were introduced.

For the second version, additional channels between chambers were added and the fins were put at an angle.

The modification of the muffler proved to significantly improve its performance. Even the first design iteration reduced the pressure drop by 50% and the maximum velocity by 38%.

The final CAD design based on the results of the simulations carried out with SimScale allowed SolidTrust’s engineers to improve pressure drop by 75% and reduce the maximum velocity by 44%.

At operating conditions, the newly developed muffler is expected to bring a significant noise reduction and better working conditions for the engine.

Sign up for SimScale

and start simulating now