The hydrogen fuel cell is an essential component of emerging sustainable energy programs. In our search for greener energy, hydrogen fuel cells can be an effective solution.

Fuel cells are one of the cleanest and most effective technologies for producing electricity [1]. They generate electricity through an electrochemical process that combines hydrogen and oxygen, expelling water and heat as byproducts. There are several uses for fuel cells, including powering homes, automobiles, and even spacecraft.

Harnessing the full potential of a hydrogen fuel cell requires a thorough understanding of how it operates and how its performance can be optimized. To that purpose, engineers are designing effective and long-lasting fuel cell systems using fuel cell simulation and modeling phenomena like heat transfer, fluid flow, structural integrity, and electrochemical processes that take place within the fuel cell structure.

This article aims to explore the intricacies of hydrogen fuel cell simulation and modeling and the ways we can leverage them to enhance the design and performance of hydrogen fuel cells.

How Does a Hydrogen Fuel Cell Work?

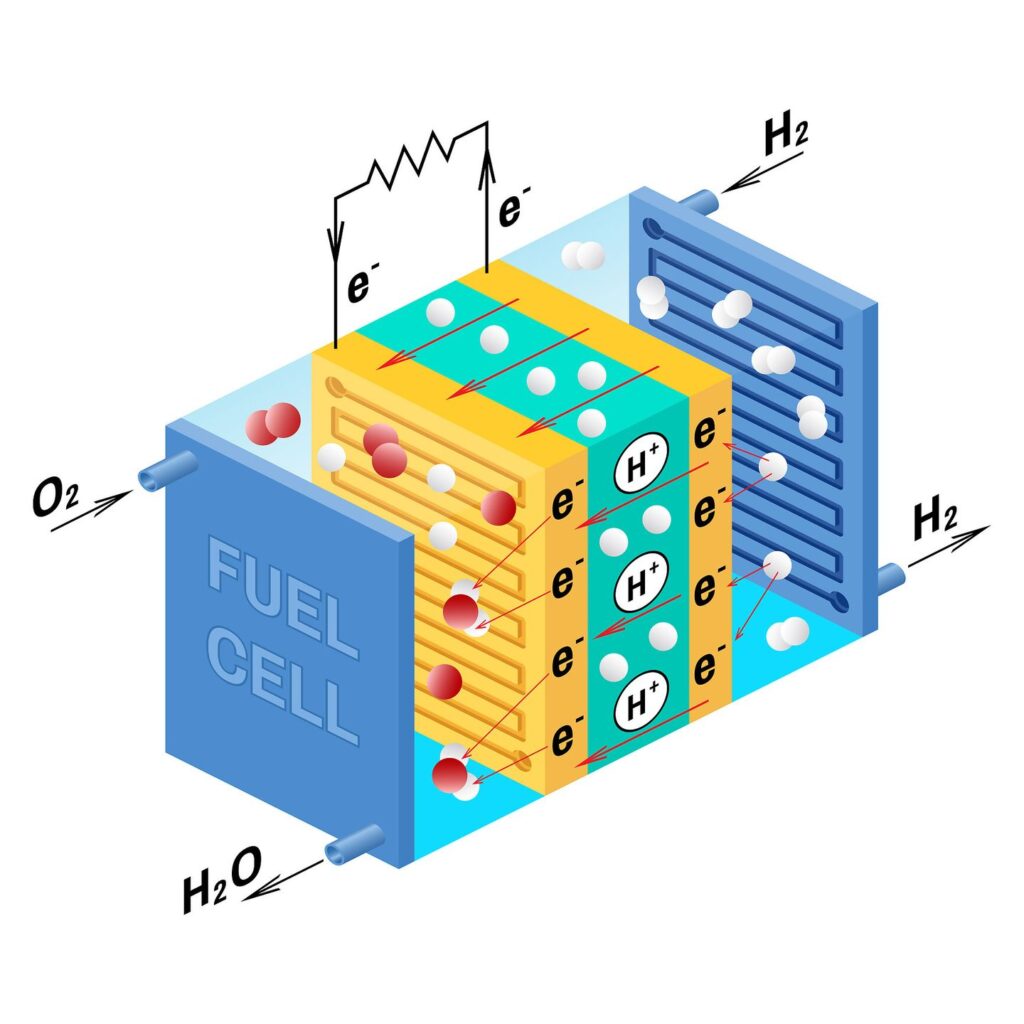

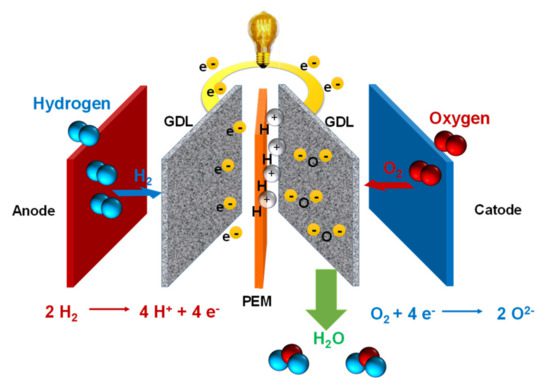

A hydrogen fuel cell is essentially an electrochemical device that produces electricity by utilizing the chemical energy generated during the interaction between hydrogen and an oxidizing substance, usually oxygen [2]. The main benefit of hydrogen fuel cells is their clean emissions, which are a drastic environmental advantage over the CO2 emissions produced by conventional energy sources. They only include heat and water as byproducts.

A fuel cell has an anode and a cathode (the electrodes) separated by an electrolyte. At the anode, Hydrogen is divided into protons and electrons.

Only protons may flow through the electrolyte, which forces the electrons to move along an external circuit and generate electrical energy. The electrons and protons interact with oxygen at the cathode to produce water.

Types of Fuel Cells

There are various types of fuel cells, primarily characterized by the electrolyte type they employ, which influences their operational properties and appropriate applications. Some of the most popular types are Polymer Electrolyte Membrane Fuel Cells, Alkaline Fuel Cells, and Phosphoric Acid Fuel Cells. Other types worth mentioning are Direct Methanol Fuel Cells, Molten Carbonate Fuel Cells, Solid Oxide Fuel Cells, and Reversible Fuel Cells [4].

Polymer Electrolyte Membrane Fuel Cells (PEMFC)

Solid polymer is used as the electrolyte in polymer electrolyte membrane fuel cells (PEM), also referred to as proton exchange membrane fuel cells. Because of their low operating temperature (about 80 °C), they can start quickly and sustain less wear. PEM fuel cells normally employ a platinum or platinum alloy as a catalyst and only need hydrogen, oxygen, and water to function. They are renowned for being both compact and having a high power density [4]. The PEMFC is one of the most promising fuel cell types, especially for use in vehicles. They are appropriate for quick start-up and shut-down cycles.

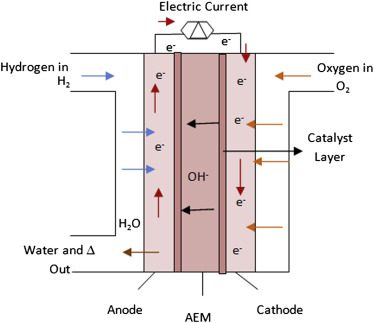

Alkaline Fuel Cells (AFC)

The electrolyte in these cells is an aqueous solution of sodium hydroxide or potassium hydroxide. AFCs typically function at temperatures below 100 °C. They are primarily powered by hydrogen gas and oxygen, though under some circumstances, other materials like zinc and aluminum may also be employed. Applications like the American space shuttle orbiters have made use of AFCs [6].

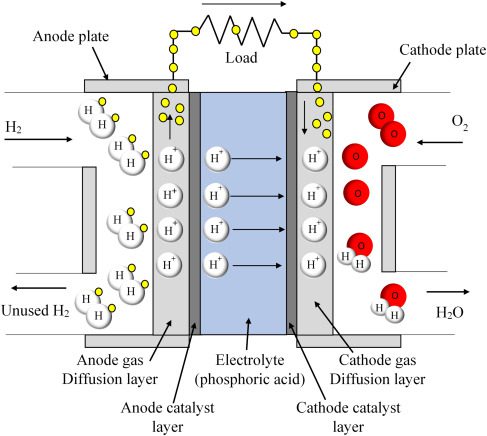

Phosphoric Acid Fuel Cells (PAFC)

These fuel cells have an efficiency of roughly 40–50% and operate between 150–200 °C. The phosphoric acid is the electrolyte. At high temperatures, they can tolerate fuel impurities, but at lower temperatures, they can be damaged by carbon monoxide. Hospitals, lodging facilities, workplaces, airports, and educational institutions use PAFCs [8].

Simulating and Modeling Fuel Cells

Simulation and modeling of fuel cells permit the analysis of complicated phenomena prior to actual implementation, saving time and money.

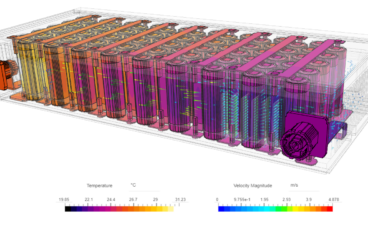

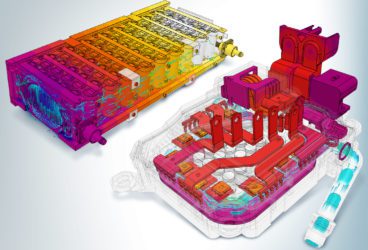

By enabling engineers to visualize multiple complex phenomena (like heat transfer, fluid flow, and structural integrity) within the cells, fuel cell simulation and modeling support the design and development of efficient and long-lasting fuel cell systems.

Simulation software like SimScale can help perform measurements and analyses that would be otherwise difficult to do in situ. SimScale is an all-in-one, cloud-native simulation software across CFD, FEA, and Thermal Analysis that enables users to conduct their analyses directly in their browser.

Engineers can simulate and optimize hydrogen fuel cell designs with SimScale, minimizing the need for costly physical prototypes. It offers crucial insights into the design and operation of fuel cells, including how different operating and environmental parameters affect performance. For instance, engineers can investigate various hydrogen fuel cell topologies and evaluate design trade-offs to ensure optimal performance and reliability of the fuel cell.

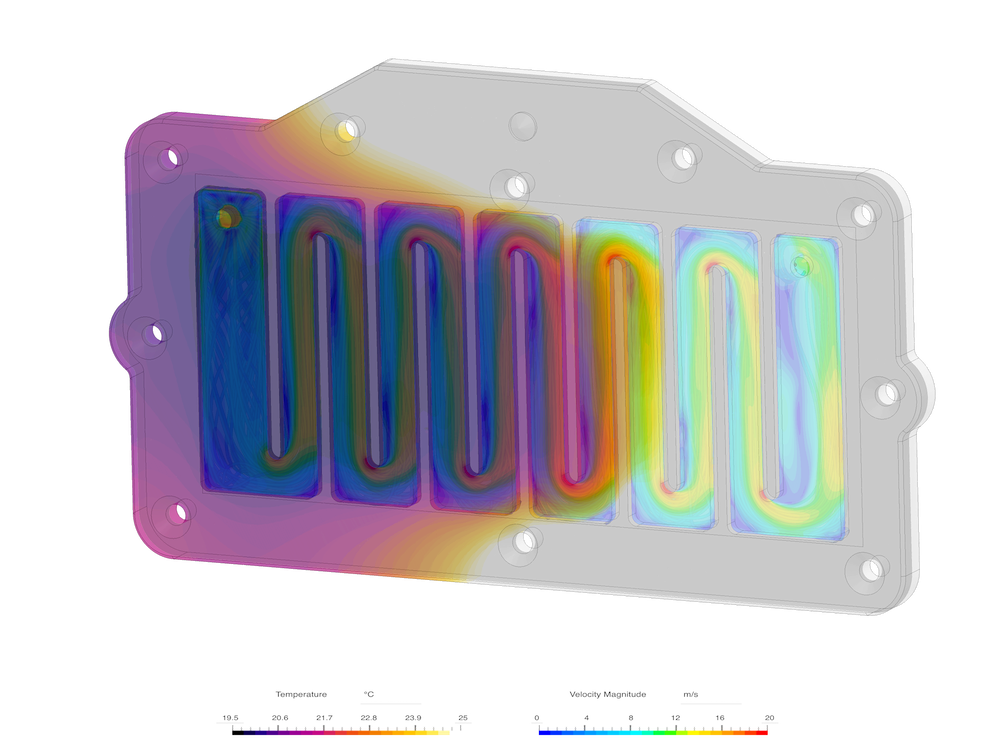

Thermal Analysis of Hydrogen Fuel Cell

Heat management poses a significant challenge in operating hydrogen fuel cells because it directly affects cell performance and efficiency, particularly in air-cooled PEM fuel cells [8]. If the heat generated by the fuel cell’s electrochemical process is not effectively controlled, it may harm its components or worsen its performance. Therefore, it is essential to have a thorough understanding of the thermal behavior and heat sources within the fuel cell system [10].

PEM fuel cell thermal management requires effective heat removal and a uniform temperature distribution. The latter is made even more challenging by low-temperature generated heat and limited exchange regions, particularly in mobile applications [11].

A thermal analysis tool can address these issues quickly and help predict airflow, temperature distribution, and heat transfer, owing to its accessibility, scalability, and capacity to run multiple simultaneous thermal simulations in parallel. The stack, the anode and cathode gas supply subsystems, and the tail gas exhaustion subsystem can all be included in the simulation’s overall model of the PEM fuel cell system.

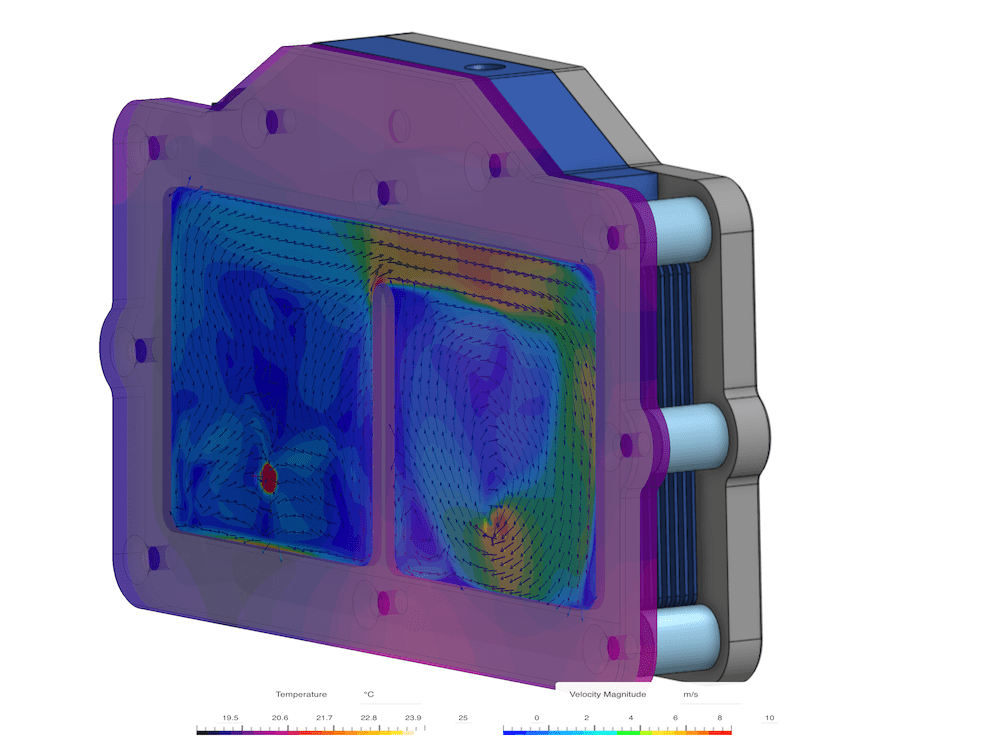

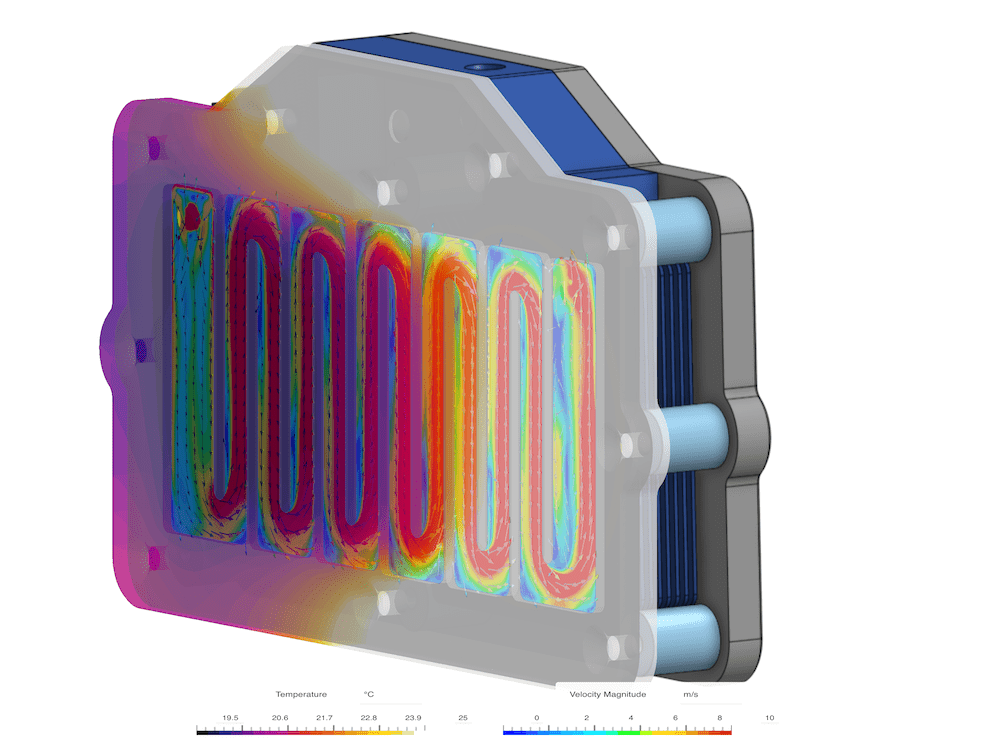

In the example below, a multiphysics simulation of a cooling plate for a hydrogen fuel cell was run in SimScale. Different design iterations were studied using thermal analysis and flow analysis to identify the best design for optimal cooling. To further explore and analyze this application, you can simply copy the project by clicking on the “Copy Project” button and run your own simulations with your desired parameters.

Case Studies of Hydrogen Fuel Cell Simulation

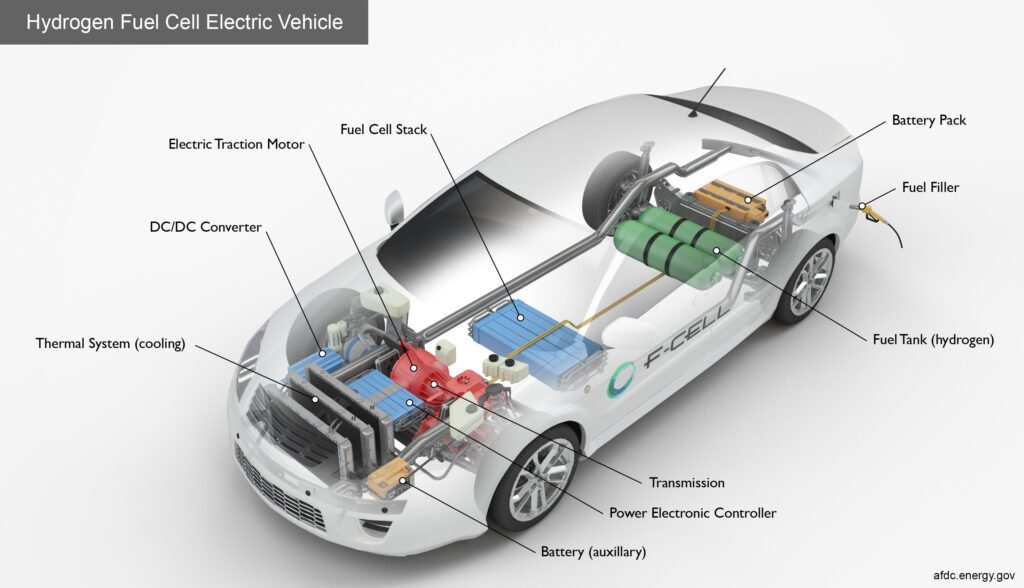

Hydrogen fuel cell simulations have been effectively used in a number of industries, emphasizing their critical importance in the advancement of clean energy. The automotive industry serves as a prime illustration of this, with engineers creating fuel cell systems for automobiles.

So, how does the hydrogen fuel cell work in this context? PEM fuel cells provide an alternative to fossil fuels by converting chemical energy from hydrogen into electrical energy. However, building these systems for real-world applications necessitates a thorough examination of a wide range of factors, from fluid dynamics to heat management.

In a noteworthy work, PEM fuel cells with metal foam were simulated to enhance overall cell performance [13]. The simulation showed that the use of metal foam leads to a more uniform distribution of reactant gas and temperature, improving fuel cell performance.

Another successful application involves marine power systems. For efficient scaling and feasibility studies, which are crucial for correct sizing in maritime applications, several PEM fuel cells were simulated to understand the PEM fuel cell behavior at different sizes and configurations in power systems [14].

SimScale provides various industries, including the automotive and energy industries, with simulation and analysis tools that enable testing and optimization of fuel cell designs early in the design process. With its cloud-native multiphysics capabilities, engineers can leverage SimScale’s powerful solvers and ease of use to run multiple simulations in parallel directly in their web browser without having to worry about expensive hardware. This enables collaboration across the product design cycle by simply sharing the simulation project with team members with a simple click of a button.

Future of Hydrogen as Fuel

The technology for hydrogen fuel cells has a promising and ever-expanding future. Recent advancements include enhancing PEM fuel cell performance with novel materials like metal foam and improving temperature distribution and reactant gas flow [13].

Using software like SimScale, researchers, engineers, and designers all over the world are utilizing fuel cell simulation to innovate faster, optimize their designs early in the design process, and boost their R&D efforts. According to current trends, hydrogen fuel cell designs should be optimized for particular uses where thorough simulations are essential for feasibility studies and appropriate scaling [14].

A majority of energy and utility companies are expected to invest in low-carbon hydrogen initiatives by 2030 [15], reflecting the industry’s particular interest in hydrogen. As a result, hydrogen has the potential to influence a number of industries and lead to a cleaner and more sustainable future.

By 2030, the value of the hydrogen economy could reach $500 billion. Achieving commercial feasibility and ensuring effective storage and production are two issues that have hindered its implementation so far [16]. Additionally, continued research is needed to improve heat transfer and decrease energy waste in PEM fuel cells [17].

Nevertheless, these difficulties also bring about new possibilities. The integration of cloud-based simulation software like SimScale into the design workflow allows for more extensive testing and development of solutions in a cost-effective manner. The use of hydrogen as a fuel has enormous promise as the world shifts to cleaner energy.

Hydrogen fuel cells have enormous promise for the development of a sustainable future. As we have seen, these cells use an eco-friendly electrochemical method to produce energy, with the only waste being heat and water.

Engineers can use platforms like SimScale’s fuel cell simulation and modeling tools to develop and tune these cells for best performance and longevity.

What does the future hold for hydrogen fuel cells? Only time will tell. With the help of advanced simulation and modeling tools like SimScale, engineers and designers can contribute to the development of hydrogen fuel cells toward a greener, more sustainable future.

References

- Felseghi, R.A. et al., “Hydrogen Fuel Cell Technology for the Sustainable Future of Stationary Applications,” Energies 2019, 12, 4593; doi:10.3390/en12234593

- Jain, K. and Jain, K., “Hydrogen Fuel Cell: A Review of different types of fuel Cells with Emphasis on PEM fuel cells and Catalysts used in the PEM fuel cell,” International Journal of All Research Education and Scientific Methods (IJARESM), ISSN: 2455-6211, Volume 9, Issue 9, 2021

- Bhatia, A., “Introduction to Fuel Cells. An Online PDH Course,” Course No.: R07-001, 2023. Available: CEDengineering, https://www.cedengineering.com/userfiles/Introduction%20to%20Fuel%20Cells.pdf

- Energy.Gov, “Types of Fuel Cells,” Office of Energy Efficiency & Renewable Energy. Available: Energy.Gov, https://www.energy.gov/eere/fuelcells/types-fuel-cells

- Tellez-Cruz, M. M. et al., “Proton Exchange Membrane Fuel Cells (PEMFCs): Advances and Challenges”, Polymers 2021, 13(18), 3064; https://doi.org/10.3390/polym13183064

- Schumm, B., “Types of Fuel Cells,” Britannica. Available: Britannica, https://www.britannica.com/technology/fuel-cell/Types-of-fuel-cells

- Dharmalingam, S. et al., “Chapter 1.7 – Membranes for Microbial Fuel Cells”, in Biomass, Biofuels and Biochemicals, Microbial Electrochemical Technology, Elsevier, 2019, Pages 143-194, https://doi.org/10.1016/B978-0-444-64052-9.00007-8

- Sunden, B., “Fuel Cell Types – overview,” Academic Press, published in Hydrogen, Batteries and Fuel Cells, 2019, pages 123-144, https://doi.org/10.1016/B978-0-12-816950-6.00008-7

- Kamran, M., “Chapter 7 – Fuel cell”, in Renewable Energy Conversion Systems, Academic Press, 2021, Pages 221-242, https://doi.org/10.1016/B978-0-12-823538-6.00005-1

- Ondrejicka, K. et al., “Modeling of the air-cooled PEM fuel cell,” IFAC PapersOnLine 52-27 (2019) 98–105. Available: Science Direct https://www.sciencedirect.com/science/article/pii/S2405896319326898

- Ramousse, J. et al., “Heat sources in proton exchange membrane (PEM) fuel cells,” Journal of Power Sources, Volume 192, Issue 2, 15 July 2009, Pages 435-441. Available: Science Direct https://www.sciencedirect.com/science/article/abs/pii/S0378775309005485

- Alternative Fuels Data Center, “How Do Fuel Cell Electric Vehicles Work Using Hydrogen?”, Available: https://afdc.energy.gov/vehicles/how-do-fuel-cell-electric-cars-work

- D’Adamo, A. and Corda, G., “Numerical Simulation of Advanced Bipolar Plates Materials for Hydrogen-Fueled PEM Fuel Cell,” SAE Technical Paper 2022-01-0683, 2022, https://doi.org/10.4271/2022-01-0683. Available at: SAE, https://www.sae.org/publications/technical-papers/content/2022-01-0683/

- Afshari, E., “Computational analysis of heat transfer in a PEM fuel cell with metal foam as a flow field,” Journal of Thermal Analysis and Calorimetry, 139 (4), 2019, DOI:10.1007/s10973-019-08354-x. Available: Research Gate, https://www.researchgate.net/publication/333083577_Computational_analysis_of_heat_transfer_in_a_PEM_fuel_cell_with_metal_foam_as_a_flow_field

- Bagherabadi, K.M. et al., “Dynamic modelling of PEM fuel cell system for simulation and sizing of marine power systems,” International Journal of Hydrogen Energy, Volume 47, Issue 40, 8 May 2022, Pages 17699-17712. Available: Science Direct, https://www.sciencedirect.com/science/article/abs/pii/S0360319922013970#preview-section-snippets

- Bharadwaj, A., “H2 – The Future of Automotive Fuel”. Capgemini. Available: CapGemini, https://www.capgemini.com/insights/expert-perspectives/hydrogen-the-future-of-automotive-fuel/

- The Economist, “Hydrogen: the fuel of the future?” The Economist. Climate Essentials, 2021. Available: Economist, https://www.economist.com/films/2021/08/25/hydrogen-the-fuel-of-the-future