It was yet another beautiful evening on July 26, 2016, in St. Louis, US. At around 8.15 pm, a fire started in a downtown parking garage. Multiple vehicles were involved and smoke engulfed a complete floor of the garage.

Fortunately, emergency services responded quickly and were able to control the flames. No one was injured in this case. A lucky factor that contributed to this relatively positive outcome was that the garage itself was not underground. This meant that it had enough surrounding ventilation to reduce heat and smoke—thus reducing the risk of fire spread, explosion, and flashover—and facilitate the safe evacuation of all persons in the building by firefighters.

In 2016 alone, there were four similar parking garages accidents. The consequences could have been tragic if a similar occurrence happened in an unmanaged underground parking garage. But this isn’t necessarily a reason to avoid as underground parking; in fact, they can reduce the emissions by about 40% compared to kerbside parking [1].

The air quality in closed environments is a growing concern. Apart from smoke and fire, carbon monoxide (CO) and particle-bound polycyclic aromatic hydrocarbons (pPAH) levels need to be constantly monitored and managed [2]. Studies have revealed that, in parking garage employees, 13 to 18% of the blood is CO saturated [3].

A number of research papers have investigated the pollution effects in underground parking garages. So how do we achieve proper ventilation in these conditions, and find a solution to this problem? In this regard, there are two elements of the problem that needs to be addressed:

- Study of smoke or contaminant propagation

- Clearance of smoke or contaminant from the underground garage through a SHEV (smoke and heat exhaust ventilation system)

Garage Ventilation Smoke Propagation in Underground Garage

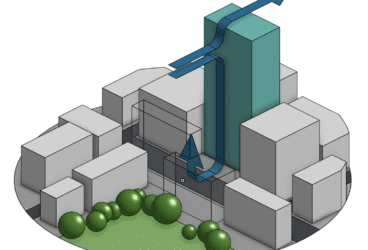

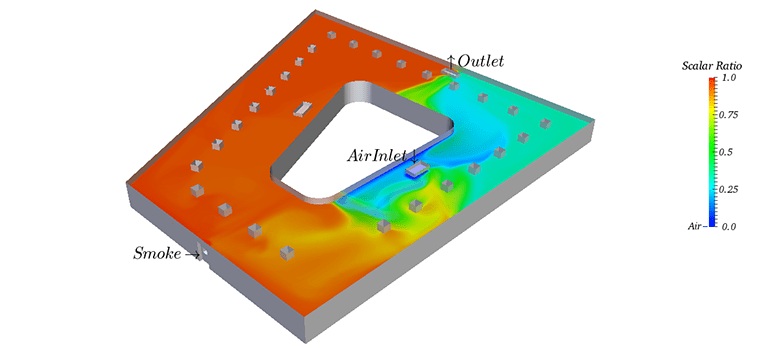

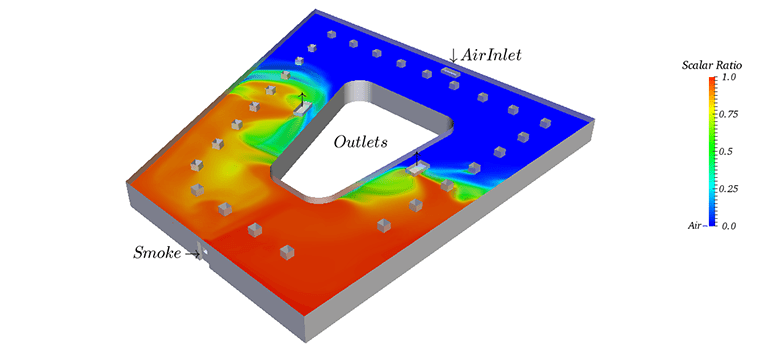

Why is this study significant? It is important to understand how ventilation affects the propagation of smoke or any other contaminant in a closed environment. The simulations are carried out with SimScale in an underground parking garage with different combinations of ventilation systems for smoke control. Look at the two images below. In both cases, smoke is coming from a particular point. In order to tackle an emergency, it is critical to understand how smoke circulates in the environment from the fire source. The term ‘scalar ratio’ is one where the value 1 refers to smoke and 0 refers to air, and the term ‘smoke ratio’ refers to the percentage of smoke present in the entire domain. The lesser the value of ‘smoke ratio’, the better the ventilation in the closed space.

Case 1: The average smoke ratio in this instance is 0.754, which represents that 75.4% of the garage is covered by smoke. This can be seen from the fact that a larger area in the domain is covered by red.

Case 2: The same setup is altered only by changing the inlet and outlets. The results are obtained after the same amount of time has passed—around 30 minutes in these trials—in order to compare them. In this case, the smoke ratio is 0.417, which reveals that this setup has one-third less smoke than the previous model.

What conclusions can we draw from this study? There are specific areas that are less prone to the effects of pollution. These could become designated emergency zones, so people can move to the lowest risk areas of the building during emergencies and accidents to minimize the health hazards.

Download this case study for free to learn how the SimScale CFD platform was used to investigate a ducting system and optimize its performance.

Garage Ventilation Smoke Clearance: Choosing a Good Ventilation System for Smoke Control

The next round of analysis is to find an efficient ventilation system for smoke control to clear a contaminated room. In the following analyses, the room is initialized to have a scalar ratio of 0.5, i.e. the room is contaminated by pollutants up to 50%.

Case 1: The domain has its inlets and outlets as shown below in the figure. The average smoke ratio is 0.166 after passing in the air for about 1.5 hours.

Case 2: The comparable smoke ratio in this configuration is 0.123 after the same duration. This illustrates that case two has better purification capabilities than the previous one.

These are just a few examples of smoke propagation or clearance through smoke control ventilation systems. These examples help us understand the importance of engineering simulation (in this case, mainly CFD) when designing proper ventilation systems.

In actual design methods for smoke control applications, all possible combinations should be tested, while also assuming the source of pollution to be at different points of the garage. The argument can also be extended to find the most energy-efficient type of ventilation. Hence, the simulation study proves to be a very simple method of gathering information that can save money, time, and potentially lives.

To learn more watch the recording of this workshop on smoke propagation and clearance. This smoke simulation project can be found here, which can be copied and worked upon to understand how engineering simulation works!

References

- Paul G. Höglund, Parking, energy consumption and air pollution, Science of The Total Environment, Volumes 334–335, 1 December 2004, Pages 39-45, ISSN 0048-9697

- Sung R. Kim, Francesca Dominici, Timothy J. Buckley, Concentrations of vehicle-related air pollutants in an urban parking garage, Environmental Research, Volume 105, Issue 3, November 2007, Pages 291-299, ISSN 0013-9351

- James M., Ramsey MS., Carboxyhemoglobinemia in Parking Garage Employees, Archives of Environmental Health: An International Journal, Volume 15, Number 3, 1967, Pages 580-583