Test, validate, and optimize valve designs iteratively and easily in a cloud-based platform

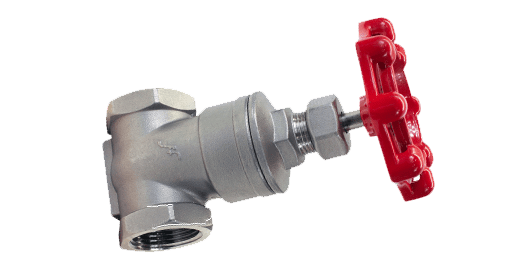

A gate valve, or sluice valve, differs from other applications in its family as it operates by raising a barrier up and down to control the fluid path. These types of valves require minimal space along a pipe’s axis, and have an extremely low resistance to fluid flow when the barrier is fully lifted allowing full stream power. A gate valve design’s main goal is to shut off the flow of fluid.

These types of valves are utilized in a number of different industrial applications, including but not limited to:

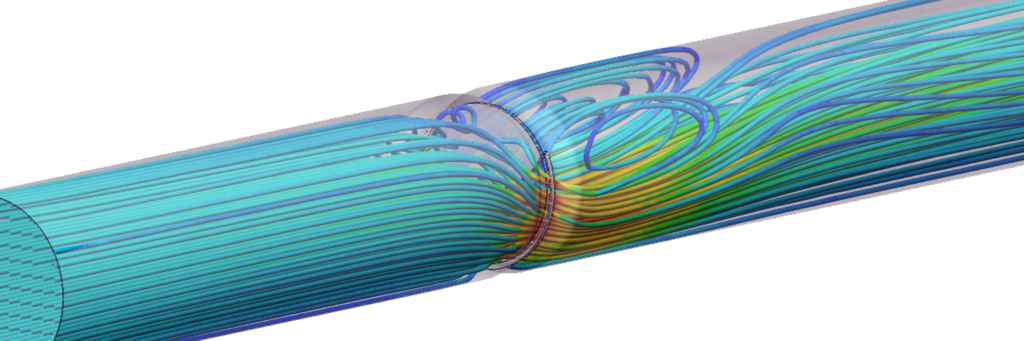

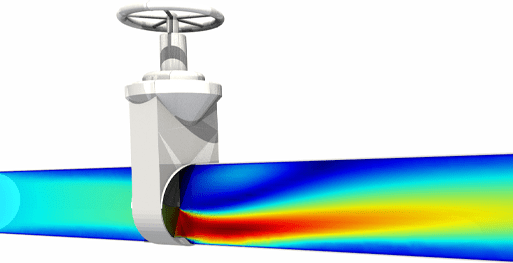

Gate valve applications need to be analyzed in the early design process to predict performance in terms of thermal as well as pressure shock. In addition to this, pressure drop and the force acting upon the walls of the valve should be evaluated.

Simulating as early as possible in the design process means more iterations and opportunities for design improvements. However, the high cost of hardware and steep learning curves of traditional, on-premises tools leave many designers to feel that virtual simulation is not an option.

SimScale has eliminated such traditional hurdles, thanks to the power of the cloud. With SimScale, engineers can:

Sign up for SimScale

and start simulating now